Amada India innovates sheet metal tech with AI, automation and proprietary laser breakthroughs

By Staff Report October 1, 2025 7:32 pm IST

The AMADA Group follows the philosophy of “Growing Together with our Customers,” with all products designed to support customers to improve profitability. According to Edwin Sequeira, President of AMADA (India) Pvt. Ltd., innovation lies at the core of their offerings, backed by over 1,000 active patents in Japan and overseas. He highlights the company’s advanced technologies and solutions in areas such as laser beam control technology, automation, and fiber welding with automation.

Amada has been introducing new technologies and solutions recently. What innovations are you most excited about right now, and how do they address current industry challenges?

The AMADA Group develops technologies that contribute to higherquality problem-solving by identifying the diverse issues faced by its customers. To provide processing technologies that align with our customers’ needs, we develop products tailored to regional characteristics and customer production activities across 16 development bases in Japan and overseas.

The AMADA Group maintains more than 1,000 patents at any given time in Japan and overseas. It conducts extensive research and development, including machines, automation equipment, control equipment, software, tooling, bandsaw blades, and processing technologies, to provide onestop solutions to our customers’ production issues.

Could you highlight some of the latest innovations?

Some of the latest technology innovations include,

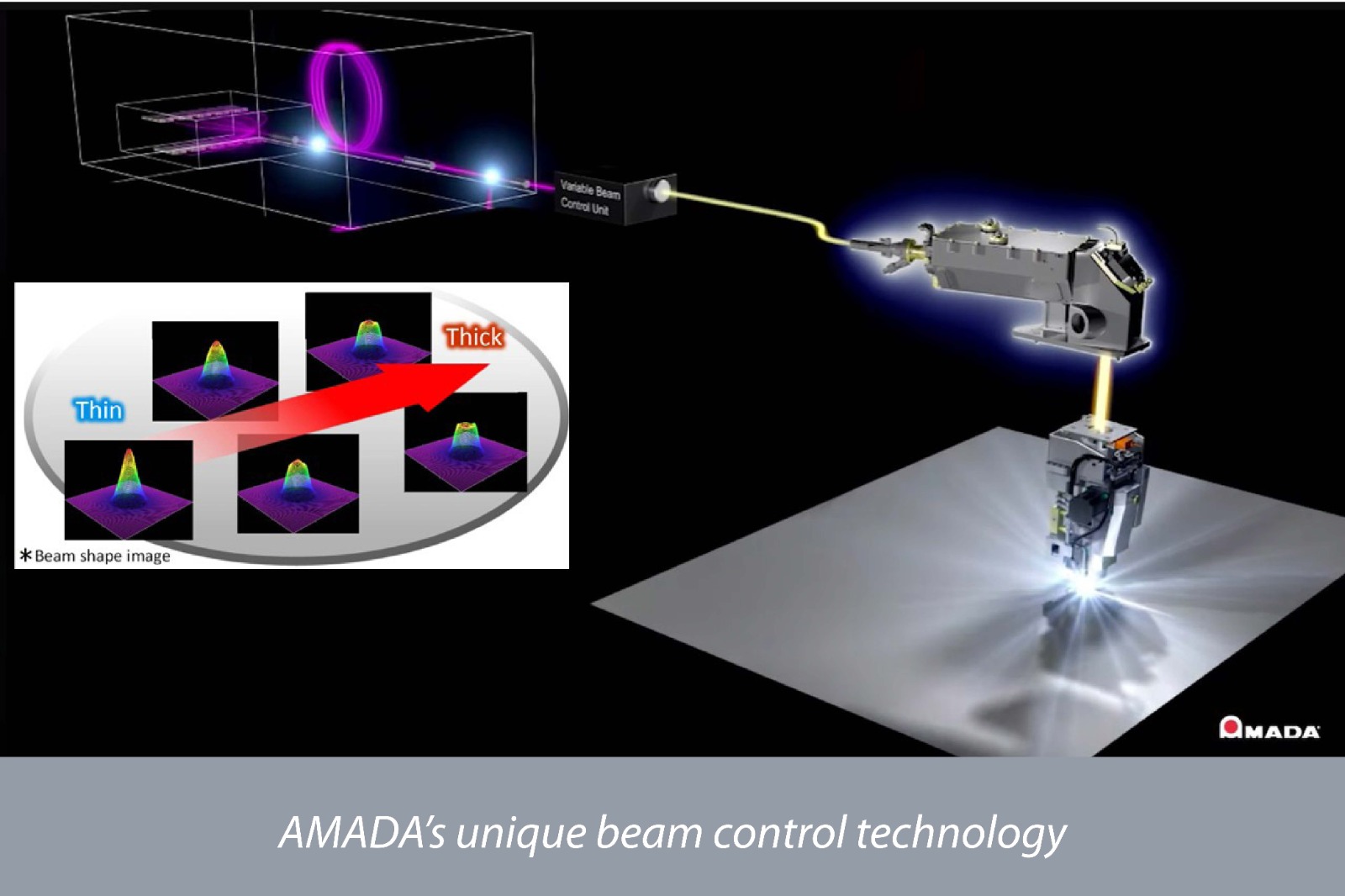

Cutting-edge laser technology: The demand for laser technology is increasing; thus, we have developed a variety of oscillators in-house, including fibre lasers, YVO4 lasers, YAG lasers, and direct diode lasers.

We have also developed proprietary technologies to control the shape and trajectory of laser beams, and have established a wide range of processing technologies for cutting, welding, marking, soldering, and laminated shaping.

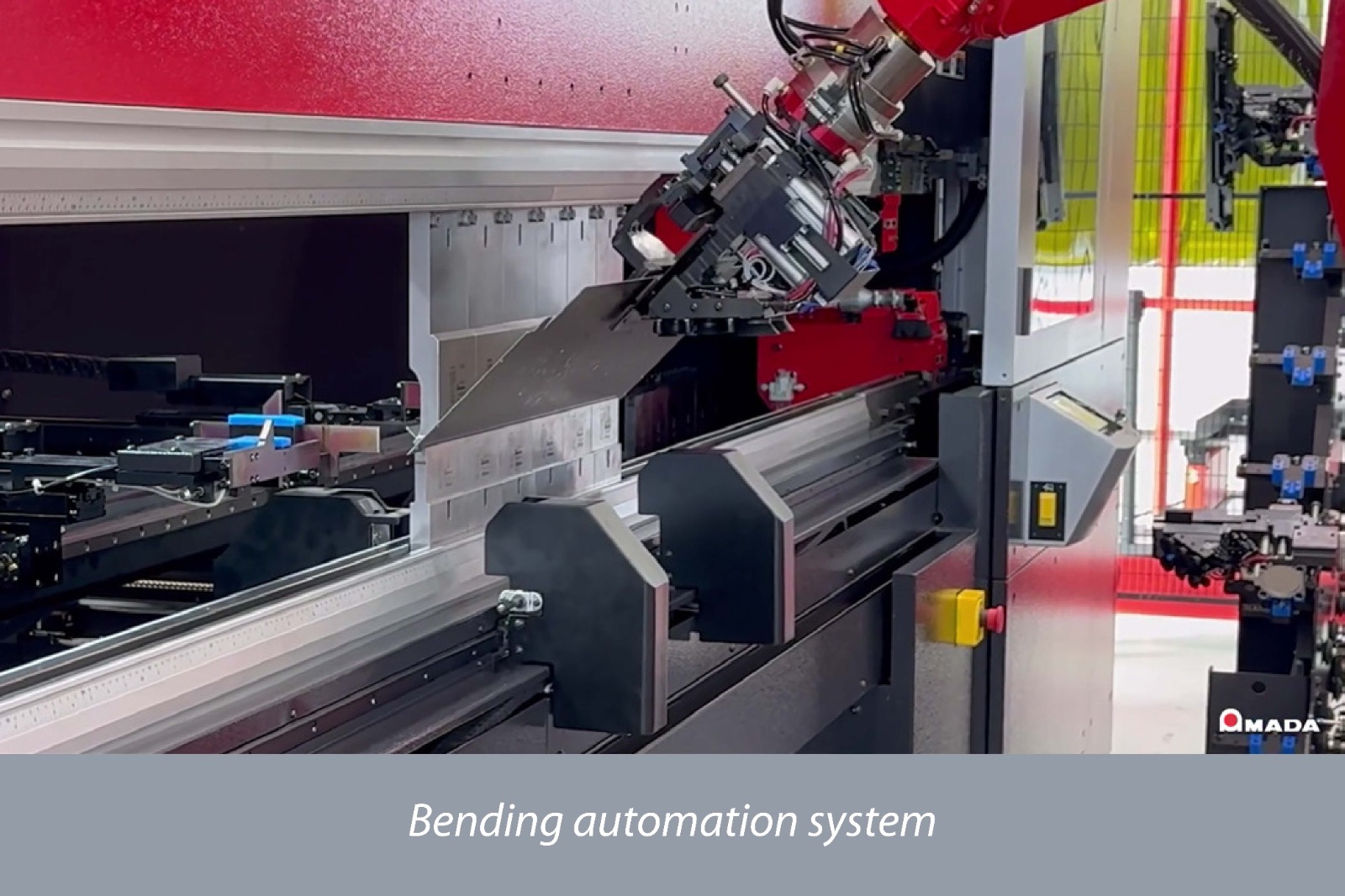

Control technology: AMADA has been working to automate bending processes since the 1980s. Despite its challenging nature, we have successfully automated bending by developing advanced coordinated control of processing machines and peripheral equipment. Furthermore, the system now automates setup work to accommodate high-mix, smalllot production. Since the 1990s, AMADA has been working to automate the even more challenging welding processes for thin sheets and has developed a compensation system using AI. Every day, we continue to develop our technologies to ensure universal usability.

Software: In machining, it is important to create accurate processing programs. AMADA develops unique automatic programming systems that use computer simulations to generate accurate programs.

We also develop systems for manufacturing DX that visualise and optimise production progress and aid productivity improvement at our customers’ plants.

We’ve seen Amada expand its capabilities in large-scale press machines and automation. How do you see these developments impacting your customers in automotive and other industries?

Recently, Amada Group acquired the large-scale press manufacturing company H&F Corporation. We can now supply large-scale press lines that produce exterior and interior panel parts for automobiles. Customers from the automobile field can get a variety of solutions from a single source.

As for the stamping press business, we handle metal stamping presses that are indispensable for the manufacturing of home appliances and automotive parts and offer a wide range of stamping presses and press system products, including electric servo-drive stamping presses.

In the stamping press equipment business, we handle coil line systems that feed coil material to presses and robot line systems that transfer workpieces between presses, offering an extensive lineup of products ranging from precision parts to automotive frame parts.

With the global market facing cost pressures and changing demand, how is Amada balancing innovation with affordability for manufacturers?

Our group’s philosophy is “Growing Together with our Customers”. Our products are well researched to support customers in terms of QCD (Quality, Cost, Delivery). Innovation is always at the heart of our products. We have introduced a new range of laser cutting machines – ORSUS3015Aje, available in 3, 6 and 8 kW power. We have developed a new processing technology, EZ Fast Cut, which doubles the productivity compared to the conventional laser cutting process and at a significant cost reduction. The EZ Fast Cut System from Amada is a laser feature that reduces nitrogenrelated costs and reliably supplies clean, dry, high-pressure air for shop air cutting.

Looking ahead, what big shifts in sheet metal fabrication do you expect in the next few years, and how is Amada positioning itself to lead that change?

The shortage of skilled manpower to operate high-technology machines is becoming a challenging task for business owners, especially in the sheet metal fabrication industry, due to the difficult working environment. Demand for automation is going to be the next big thing in this scenario.

We have Blanking, Bending, and Welding automation in our product portfolio, which we have been offering to Indian customers. In India, demand for cost-effective automation is high. We offer simple material loading/unloading automation, as well as advanced levels of unmanned automation, to our customers. We have recently supplied a few complete automation systems to our customers.

How is the IoT / AI contributing to sheet metal fabrication? Does Amada India offer such products?

India is emerging as a global hub for AI and IoT technologies. We do not want our customers to be left behind. We have recently launched an IoT Service to support our customers in real-time. Using IoT devices, our technicians can check the health of machines without travelling or stopping the customer’s machine. We inform customers to take necessary precautions before the actual breakdown happens. In the event of a breakdown, our team can quickly analyse the root cause and arrange the necessary parts to recover the machine in the shortest possible time.

LIVLOT is a new production monitoring system that can assist owners in tracking orders in real-time and predicting the exact delivery time. We also offer My V-Factory software, which can monitor and highlight the machine’s efficiency at any time, from anywhere, on internet-enabled mobile devices.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.