Improve on-machine measurement with SupaTouch technology

By OEM Update Editorial October 8, 2018 3:15 pm IST

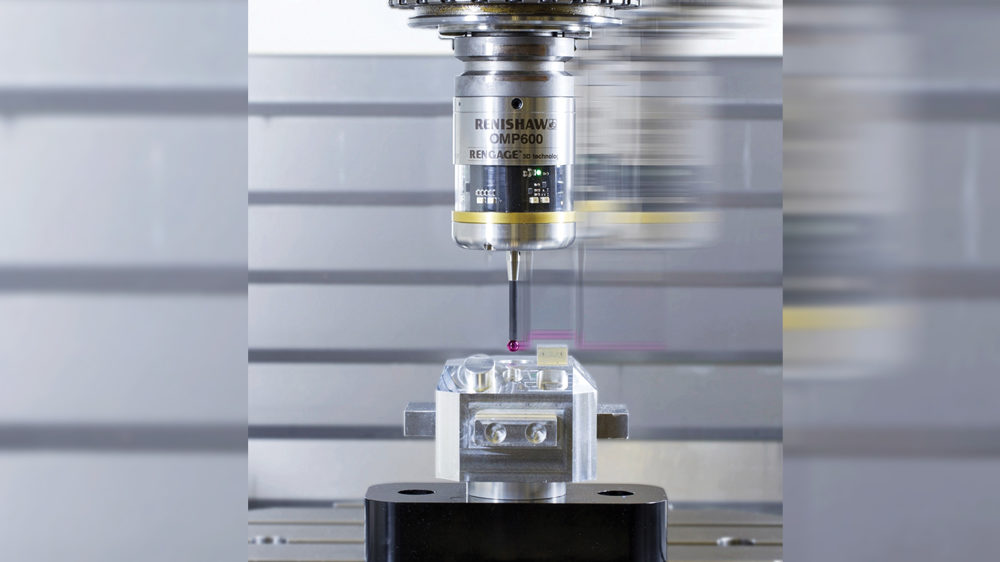

It’s not an easy task to minimise probing cycle time on a machine. Renishaw, based on its years of metrology experience, has identified that intelligent optimisation is needed to minimise probing cycle time without compromising on machine component accuracy.

SupaTouch, an optimisation routine within Renishaw’s industry standard Inspection Plus macro software, intelligently optimises on machine probing cycles, leading to a cycle time reduction of up to 60 per cent on CNC machine tools.

Renishaw will be introducing a new version of Inspection Plus, with updated SupaTouch technology, at IMTS (USA), AMB (Germany), and JIMTOF (Japan). New usability enhancements that have been added to the optimisation routine give users full control of probing cycle feed rates.

SupaTouch technology intelligently determines the fastest feed rates a machine tool can achieve whilst ensuring repeatable measurement. Its smart in cycle decision making technology implements the quickest probing strategy (either one touch or two touch) for each measurement.

www.renishaw.com/supatouchCookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.