Digitalisation substantially enhances operational efficiency

By OEM Update Editorial September 30, 2023 3:05 pm IST

According to Sanjeev Arora, President, Motion Business, ABB India, the primary focus remains centred on sustainability and reliability, encouraging the widespread adoption of high-energy-efficient motors and variable-speed drives.

Please discuss ways to improve electrical motor solutions’ performance and energy efficiency.

Advanced technology is imperative for the global shift towards sustainability in electric motion. As the global embrace of electric technologies continues, there is a projected twofold increase in the demand for energy-efficient motion solutions by 2040.

There has been a consistent improvement in the effectiveness and capabilities of electric motors. Some of the key factors that have enabled and will continue to enable further advancements include the availability of superior materials, improvements in manufacturing techniques, the utilisation of Multiphysics computational tools, and the growing trend of using Variable Frequency Drives (VFDs) for variable-speed applications, particularly those involving centrifugal loads.

To illustrate, approximately 45 percent of the electricity generated worldwide is transformed into motion by electrical motors. In India, a substantial installed base of motors with low efficiency exists, referred to as IE1. To foster growth and enhance performance, it is imperative to transition to at least IE3 as the minimum efficiency standard. It is also essential to educate customers about the long-term benefits of cutting-edge technologies that offer efficiency levels of IE5 or more, even if they require a higher upfront investment.

Please talk about ABB Motion’s business activities, specifically focusing on motors, drives, and related areas.

Our pioneering products, including drives, motors, generators, and comprehensive integrated digital powertrain solutions, are leading the way towards a low-carbon future across various industries, cities, infrastructure, and transportation sectors.

Our primary focus is on energy efficiency, sustainability, and reliability. We provide IE5 efficiency synchronous reluctance motors and ultra-low harmonic drives, which limit current harmonics to less than 3 percent. ABB’s Motion Business area delivers many products, including low and high-voltage motors, generators, variable frequency drives, PLCs, traction motors, converters, batteries, and chargers. Additionally, we offer complete package solutions that incorporate these products seamlessly.

Our Service division goes beyond commissioning and post-sales support for our products. We assist customers in their digital transformation journey, particularly in areas such as predictive maintenance, energy assessment, and optimising the operations of industrial power and drive systems through our digital offerings.

What recent advancements have been made in power transmission and integrated digital powertrain solutions?

Through digital powertrain, we monitor the health of variable frequency drives, motors, and the driven equipment. The analytics and dashboard help in predictive maintenance, avoiding unplanned downtimes while increasing the availability and OEE.

There is a growing interest in the efficiency of the complete system rather than looking only at individual components of the drivetrain. Due to dynamism in the operations, the systems work at the best efficiency points. Energy appraisal of the drive system is a good starting point to identify improvement areas. The use of IE2 efficiency VFDs and IE4 / IE5 efficiency motors, along with high efficiency driven equipment, go a long way in improving the system efficiency.

What are the advantages of implementing IE3 as the minimum efficiency standard in India?

As Energy efficiency becomes a centre point in reducing climate change risks, the need to promote the adoption of sustainable technologies gains greater significance.

Electric motors are designed to operate for 20 years or more. In the total cost of ownership (TCO) of the motor, which is the cost incurred during the motor’s lifetime, the purchase cost is less than 5 percent. The majority of this is the energy cost to run these motors. Though buying higher-efficiency motors is logical, most industrial buyers, especially the OEMs, continue to focus on the purchase cost. In India, the present MEPS for motors is IE2 efficiency. IE3 motors have around 15 to 20 percent lower losses than IE2 motors, and similarly, IE4 motors have further 15 to 20 percent lower losses than IE3. Of the total motors manufactured, IE3 and IE4 constitute up to 15 percent. Regulation and mandatory MEPS (minimum energy performance standards) are essential for the mass transition. By replacing IE2 with IE3 as MEPS, savings from one year of production are greater than 1 TWh. This has a cascading effect, hence the urgency to implement. Markets like the EU have moved to IE3 and IE4 efficiencies, and coincidently, these technologies are already available in India.

Educating customers about the advantages and garnering government backing to establish efficiency benchmarks will be crucial in achieving these savings, recognising the significance of collaborative endeavours.What measures can be implemented to promote energy efficiency and sustainable solutions in industrial applications?

ABB is actively driving the energy efficiency movement, which commenced in 2021. The initial step involves measuring energy consumption at both equipment and system levels. Subsequently, assessing potential opportunities for savings and evaluating these gains after implementation is crucial. Enhancing efficiency by using higher-rated motors and driven equipment, deploying variable frequency drives to regulate operation speed and thereby boost system efficiency, holds significant importance.

Utilising variable frequency drives, particularly in systems predominantly operating at partial loads, can result in substantial energy conservation. Considering that many industrial systems tend to be overdesigned, there is an average potential for savings of around 30 percent in variable torque applications like pumps and fans. These measures, encompassing the elevation of energy efficiency to IE3 standards and advocating the adoption of energy-saving technologies such as motors and drives, are indispensable for a sustainable future.

What initiatives are necessary to facilitate technology transfer for energy efficiency, conservation, and adopting highly efficient appliances?

Our primary focus remains centred on encouraging the widespread adoption of high-energy-efficient motors and variable-speed drives. ABB India aims to empower our customers with these solutions, enabling them to fine-tune their energy consumption and reduce their carbon footprints. This commitment to sustainable development is poised to be a game-changing factor, especially as global companies consider sourcing from India.

It’s essential to elevate awareness regarding the advantages of energy efficiency and the availability of related technologies. As previously mentioned, regulations play a pivotal role in steering this transition. Even though technologies achieving IE5 efficiencies are accessible, localising and optimising costs may remain challenging until adoption rates increase and market demand surges. The availability of incentives and financing options for energy-efficiency products and projects is also crucial.

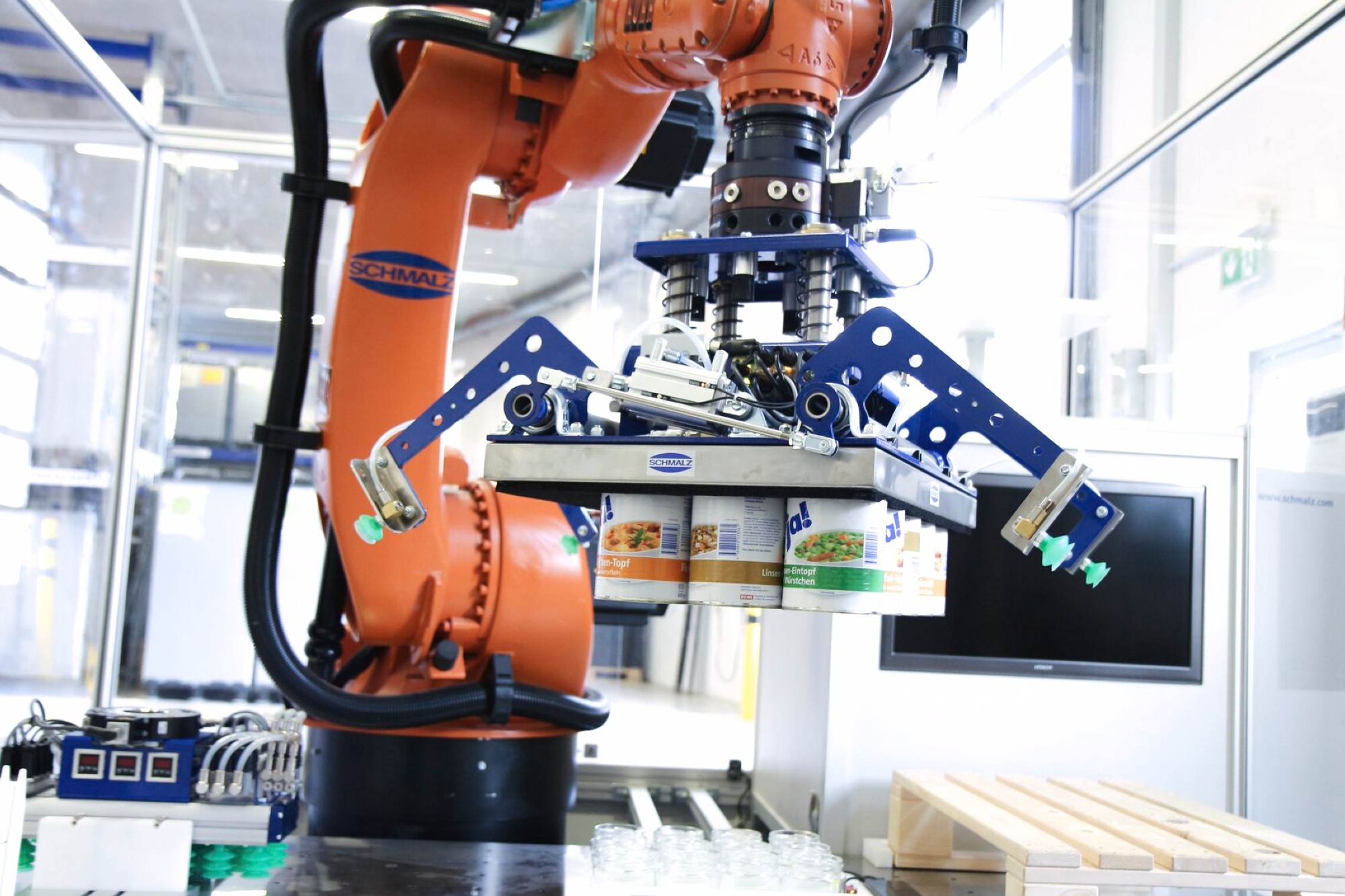

Furthermore, we acknowledge the critical role of digitalisation in overall business expansion. Digitalisation substantially enhances operational efficiency. ABB will persist in improving its facilities by implementing advanced automation and interconnected products, which enhance reliability and productivity. We have already embarked on this journey and will further strengthen our efforts.

How is ABB actively contributing to the development of a sustainable industrial ecosystem?

ABB is committed to embracing sustainability using a triple-bottom-line framework, focusing on the planet, people, and profits. Through various sustainability initiatives, we have achieved an impressive 81 percent reduction in scope one and scope two greenhouse gas emissions compared to our 2019 baseline. All our manufacturing facilities are powered by 100 percent renewable electricity and have received platinum or gold certification from the Indian Green Building Council (IGBC).

Moreover, we understand the significance of addressing scope three emissions and are actively collaborating with our suppliers, vendors, and customers to ensure their involvement in our sustainability journey. This collective effort contributes to the establishment of a sustainable industrial ecosystem.

In your opinion, what does the future hold for clean energy?

As India is poised to become the world’s third-largest economy by 2030, there is significant room for growth and development. However, this will also lead to a substantial increase in energy demand, surpassing that of any other country in the coming decades.

Therefore, prioritising a shift towards clean energy becomes imperative. India actively seeks intelligent and sustainable technological solutions to meet its expanding energy needs while minimising environmental repercussions. ABB’s ‘Energy Efficiency Movement’ aligns perfectly with the company’s Sustainability 2030 strategy, which is committed to assisting ABB’s customers in collectively reducing their CO2 footprint by 100 megatons annually by 2030. This reduction is equivalent to removing 30 million combustion cars from the roads each year.

Two key challenges emerge with the growing integration of renewable energy into the grid. The first pertains to the intermittent and uncertain nature of wind and solar energy, which is only sometimes available. This challenge can be addressed through energy storage, and ABB has established solutions for safely and reliably powering electrolysers, making green hydrogen a sustainable means of energy storage. The second challenge relates to grid management and stability, where ABB offers synchronous condensers to enhance grid stability.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.