The digital blueprint for scaling manufacturing

By OEM Update Editorial June 5, 2024 6:08 pm IST

When operations and processes are well-defined and supported by digitalisation, scaling up becomes easy without sacrificing productivity. Pawan Kumar from Cajo Technologies discusses how this can be done while discussing automation and sustainable manufacturing trends.

What are the trends and innovations impacting the automation industry?

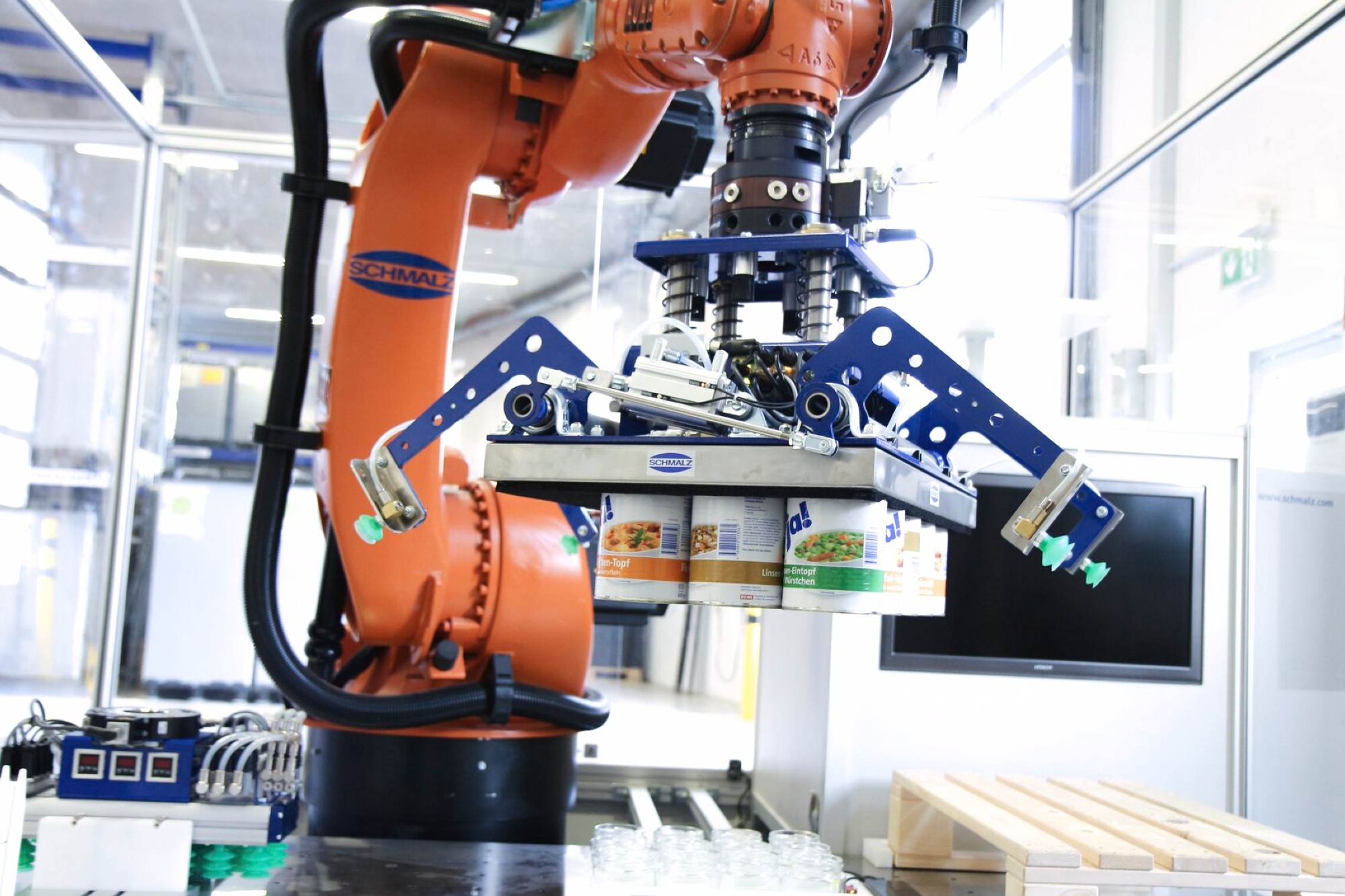

The main drivers in industries, especially automating processes, remain the same—improved productivity, quality, and elimination of unwanted processes. The industry is demanding sustainable manufacturing and the use of AI-powered tools. Sustainability can be achieved by choosing the right technology. AI-powered systems are implemented to optimise production processes, predict maintenance needs, and identify defects in real-time.

How does integrating machine vision with laser marking enhance manufacturers’ production processes?

Strategies are developed and implemented by understanding the goal. For example, we integrate machine vision with our Laser marking solution. Machine vision solutions use cameras, image processing algorithms, and software to analyse and interpret visual information. Combining marking, reading, and verification can add value for the customers. It is possible to locate the object and determine its exact marking with CajoVision™. Cutting-edge technology by Cajo helps manufacturers achieve more streamlined production processes.

What advancements are taking place in your company’s manufacturing operations?

Laser marking is quickly becoming a popular method for marking nearly any material because it is cost-effective and sustainable. It requires no additives and replaces traditional marking methods, such as inkjets and labels. Considering the ever-growing need for sustainable manufacturing, our parent company, Cajo Technologies Oy, is setting up an assembly line in Bangalore, in the heart of south India. The new set-up will be operational by the end of June 2024.

How is Cajo Technologies helping manufacturers meet sustainability goals?The challenges may differ from industry to industry. The initial goal is to define a challenge since identification is the first step to solving the challenge. Companies are adapting energy-efficient practices to meet both individual and corporate sustainability goals.

With MakeBright™ , a patent-pending new product marking technology by Cajo Technologies, packaging manufacturers can replace inkjets and the need for additives when marking and coding cardboard material. The highly sustainable technology can save hundreds of millions of litres of ink, glue, and label mass annually and improve recyclability.

How can organisations cultivate a culture promoting continual learning and upgrading employee skills?

The traditional annual review method has shortcomings due to continuous changes in the work environment. Therefore, managers’ performance management plays a part in employee development. Training workers under the supervision of experienced managers in the designated work environment gives them confidence and gradually empowers them to make self-decisions. Cajo Technologies has developed a mobile-friendly platform, CajoAcademy, which provides valuable insight into laser marking and machine vision.

What are the advantages of the Make in India initiative to scale up manufacturing?

The main aim of the Make in India initiative is to become self-reliant. It augers well with the objective of our company. We aim to reduce costs and save time. The entire process makes our lives easy and provides space to focus on other challenges coming our way.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.