Scaling up without altering the operational approach can be unsustainable

By OEM Update Editorial June 5, 2024 6:06 pm IST

Scaling up manufacturing demands innovative technologies and flexible strategies to optimise production efficiency while minimising costs. Addressing prevailing challenges, Anil Kumar, Managing Director of Inovance Technology India, emphasises customised approaches to scaling up processes within diverse industry sectors and the importance of embracing advancements in technology and automation to drive scalability and efficiency in manufacturing processes.

How do technology solutions facilitate the scaling of manufacturing operations through advanced automation technologies?

To scale up manufacturing, integrating advanced automation technologies such as robotics, artificial intelligence, and IoT (Internet of Things) can streamline operations, enhance productivity, and reduce manual labour requirements, thereby minimising labour costs and improving overall efficiency. Additionally, it is important to implement data analytics and predictive maintenance solutions to optimise equipment performance, reduce downtime, and ensure continuous operation. By leveraging these technologies strategically, manufacturers can achieve significant cost savings while scaling up their operations to meet growing demands.

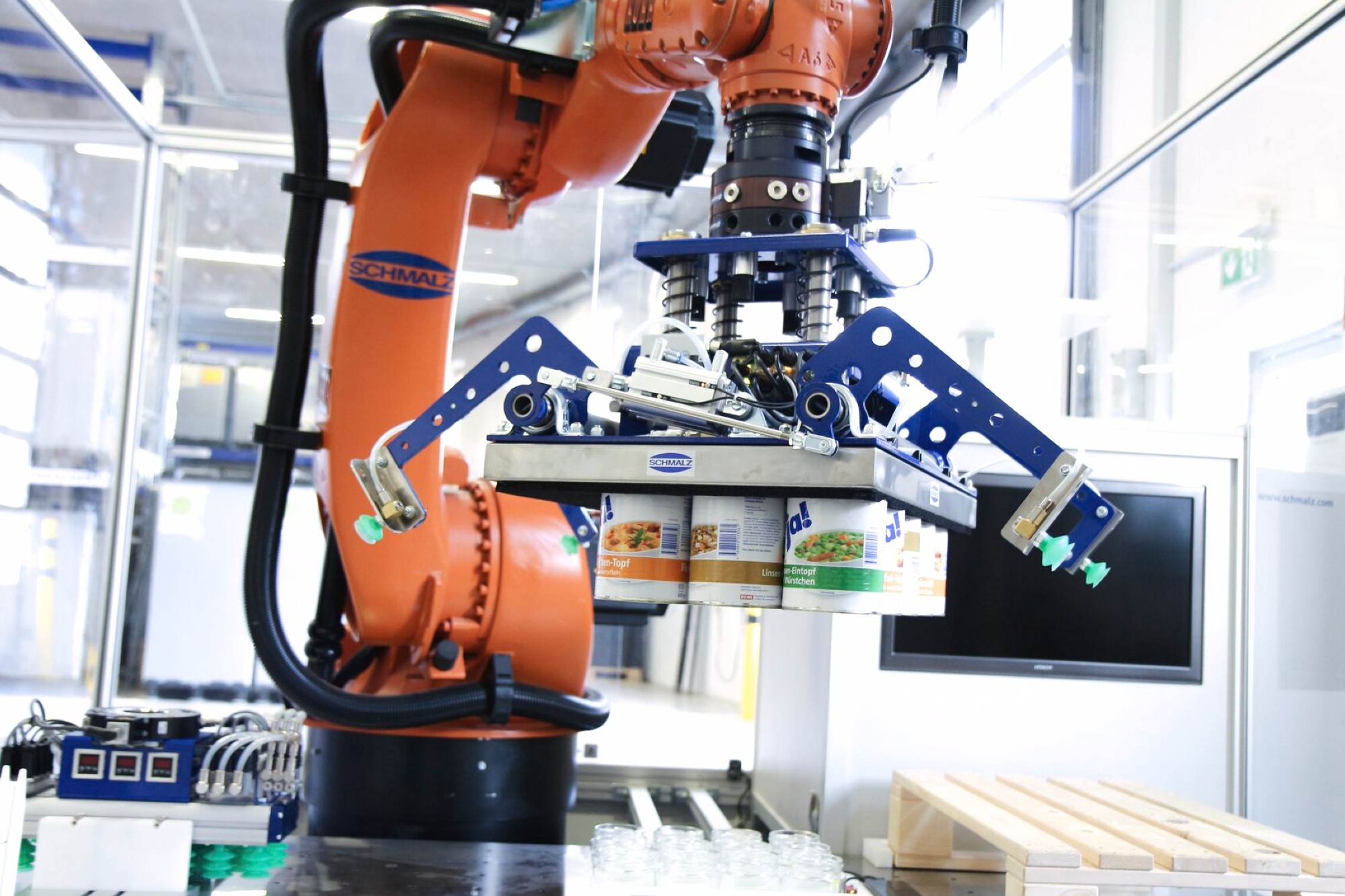

Inovance offers a comprehensive product portfolio encompassing essential components for industrial robots alongside a diverse array of integrated solutions. Our offerings comprise robot controllers, servo drives and motors, encoders, and industrial vision systems, providing a holistic suite of tools to meet the evolving needs of automation applications.

What strategies maximise the potential of advanced robotics for productivity enhancement in manufacturing?

Several approaches or strategies exist to leverage advanced robotics for precise assembly and improved productivity. Implementing advanced motion control algorithms to ensure accurate positioning and movement of robotic arms during assembly processes can be ideal. Additionally, it integrates machine learning and artificial intelligence techniques to optimise robot performance and adapt to changing production requirements in real-time. The significance of collaborative robotics, where robots work alongside human operators to maximise efficiency and flexibility on the factory floor, is a game changer. By leveraging these strategies, manufacturers can harness the full potential of advanced robotics to achieve unparalleled precision and productivity in assembly operations.

How do you address manufacturing challenges to scale up processes?

Addressing manufacturing challenges to scale up processes involves implementing strategic initiatives tailored to the specific industry. This includes optimising production workflows, enhancing supply chain management, adopting advanced technologies like automation and robotics, and investing in employee training and skill development. Additionally, fostering collaboration with suppliers and stakeholders, conducting regular performance evaluations, and continuously refining operational processes are vital steps in overcoming challenges and achieving scalable growth in the industry.Is it unsustainable to scale up without changing your operational approach?

Scaling up without altering the operational approach can prove unsustainable in the long run. As businesses expand, existing processes and systems may become inadequate to efficiently meet increased demands. Failure to adapt can lead to bottlenecks, inefficiencies, and decreased productivity. It’s essential to continually reassess and optimise operational strategies to align with evolving needs and market dynamics. Embracing innovation, leveraging new technologies, and fostering a culture of continuous improvement is crucial to sustaining growth and remaining competitive in today’s dynamic business environment.

How do Inovance’s solutions align with India’s goal of scaling indigenous production?

The advantages of the Make in India initiative for scaling up manufacturing include fostering domestic production capabilities. It reduces dependency on imports, creates employment opportunities, stimulates economic growth, attracts foreign investment, promotes innovation and technology transfer, and bolsters India’s position in global supply chains. Additionally, the initiative aims to enhance infrastructure, simplify regulatory frameworks, and encourage entrepreneurship, thereby supporting the growth of small and medium enterprises (SMEs) and contributing to overall industrial development.

In the realm of scaling up manufacturing, Inovance offers a comprehensive array of industrial automation solutions fortified by our adept engineering prowess. Our extensive product line spans AC drives, servo drives and motors, motion control systems, industrial robots, PLCs, CNCs, and HMIs. With a team of proficient engineers adept across various industrial domains such as textiles, packaging, cranes, and elevators, we specialise in tailoring solutions to address specific industry requirements. In 2020, our unwavering commitment to exceptional product quality and adherence to customer and regulatory standards culminated in Inovance India obtaining ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 certification from TUV SUD. These certifications testify to our steadfast dedication to delivering super-lative solutions that consistently surpass expectations.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.