Machining super alloys while keeping it cool

By Staff Report September 17, 2024 11:29 am IST

Additively manufactured MaxiMill – 211-DC indexable insert system with optimised coolant supply. When machining heat-resistant materials, such as titanium and other super alloys, two factors play an especially crucial role in controlling temperature and maximizing service life downtimes: top-quality tools and a targeted coolant supply. The additively manufactured MaxiMill – 211-DC indexable insert milling system showcases how proper nozzle positioning can be a true difference maker.

As anyone in the business of machining titanium parts and super alloys can attest, there is no getting around using improvised strategies aimed at cutting costs and time. Despite high-speed machining, these incredibly tough materials make it difficult to ensure process reliability. “If these processes are to be carried out in an even remotely financially viable manner, professionals often have to deviate from the proven “roadmap” and be open to trying out new strategies. It’s for such stubborn instances that we developed our 3D-printed indexable insert milling system MaxiMill – 211-DC,“ says Robert Frei, Product Manager at CERATIZIT.

3D-printed and precision-cooling

Optimised coolant is essential to achieving topquality results—especially when machining titanium and other heat-resistant materials. And it’s here where the patented shoulder mill from CERATIZIT shines—thanks to precision coolant placement on the milling indexable insert flanks.

“Additive manufacturing processes are no longer mere nice-to-haves. They are essential to achieving results that would be impossible with conventional strategies. A prime example is our indexable insert milling system, the additively manufactured MaxiMill – 211-DC,” says Frei. CERATIZIT recognized early on that 3D-printed solutions could go beyond the limits of traditional manufacturing processes and deliver viable alternatives. Developed inhouse and tailored to meet individual needs, these specially designed tools are manufactured additively.

Precision cooling that is out of this world

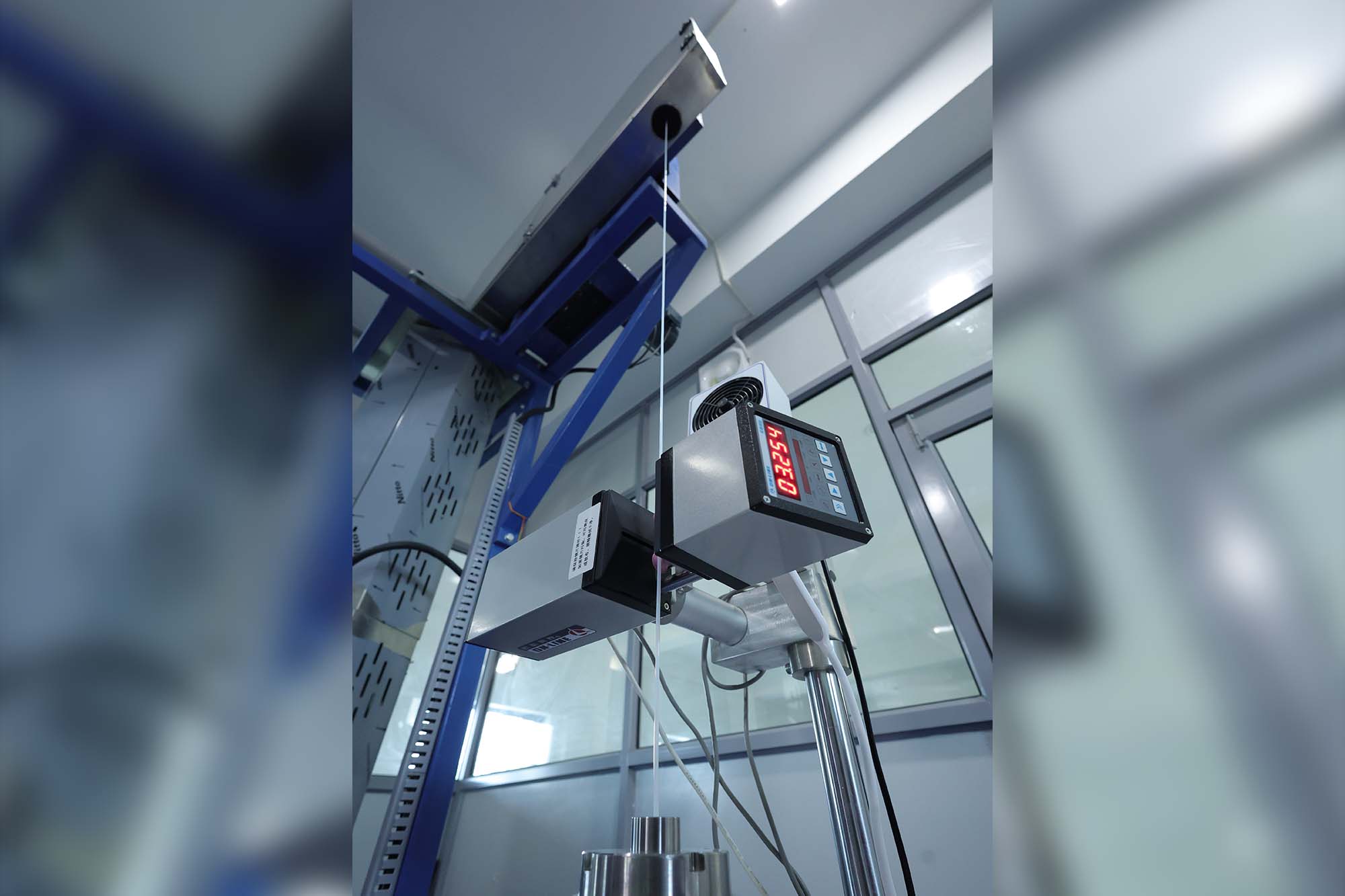

One example displaying the power of 3D-printed solutions and additive manufacturing is the base body of the milling cutter on the MaxiMill – 211-DC. CERATIZIT’s team of engineers sought to optimize the flank cooling process essential for machining titanium. “Our objective was to funnel the maximum amount of coolant directly on the flank, which sounds straightforward enough. However, pulling it off required a complex construction process, only made possible by additive manufacturing. Thus, we were able to create the perfect combination of geometric and functional properties, including the ideal nozzle position and an insert geometry precisely tailored for cooling. In doing so, we can guarantee fullcoverage wetting of the coolant on the indexable insert cutting surface.

Despite the complexity of the numerous coolant holes inside the tool body, the MaxiMill –211- DC is compatible with standard adapters with thro’ coolant supply—without requiring any standard coolant on the chip breaker. Moreover, it provides the same performance and advantages as direct cooling for turning tools.

Maximised service life

To see where the MaxiMill – 211-DC with direct cooling proves its value, look at its service life compared to tools with standard cooling: 60% longer service life. “This additional surplus of service life makes for fluid machining of titanium and super alloys while delivering the benefits of secure manufacturing processes and minimizing tool use,” says Robert Freis about using the MaxiMill – 211-DC.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.