Smart 3D vision empowers food packaging inspection

By Staff Report August 20, 2025 10:30 pm IST

To enhance the inline geometric measurement of high-variability food packaging, JLS accepted a challenge to improve its offerings. The result was approved by the customer without any modifications while increasing the output.

JLS Automation offers easy-to-use, hygienic robotic packaging solutions for the food industry that solve complex packaging challenges. Designed for sanitary environments, JLS custom vision-guided primary and secondary robotic packaging systems are user-friendly, easy to operate, fast to start up, and provide worker and food safety. Their proprietary robotic tooling and high-speed leak detection systems have been awarded several patents. JLS prides itself on offering unrivalled partnership and aftermarket support to its customers.

The application

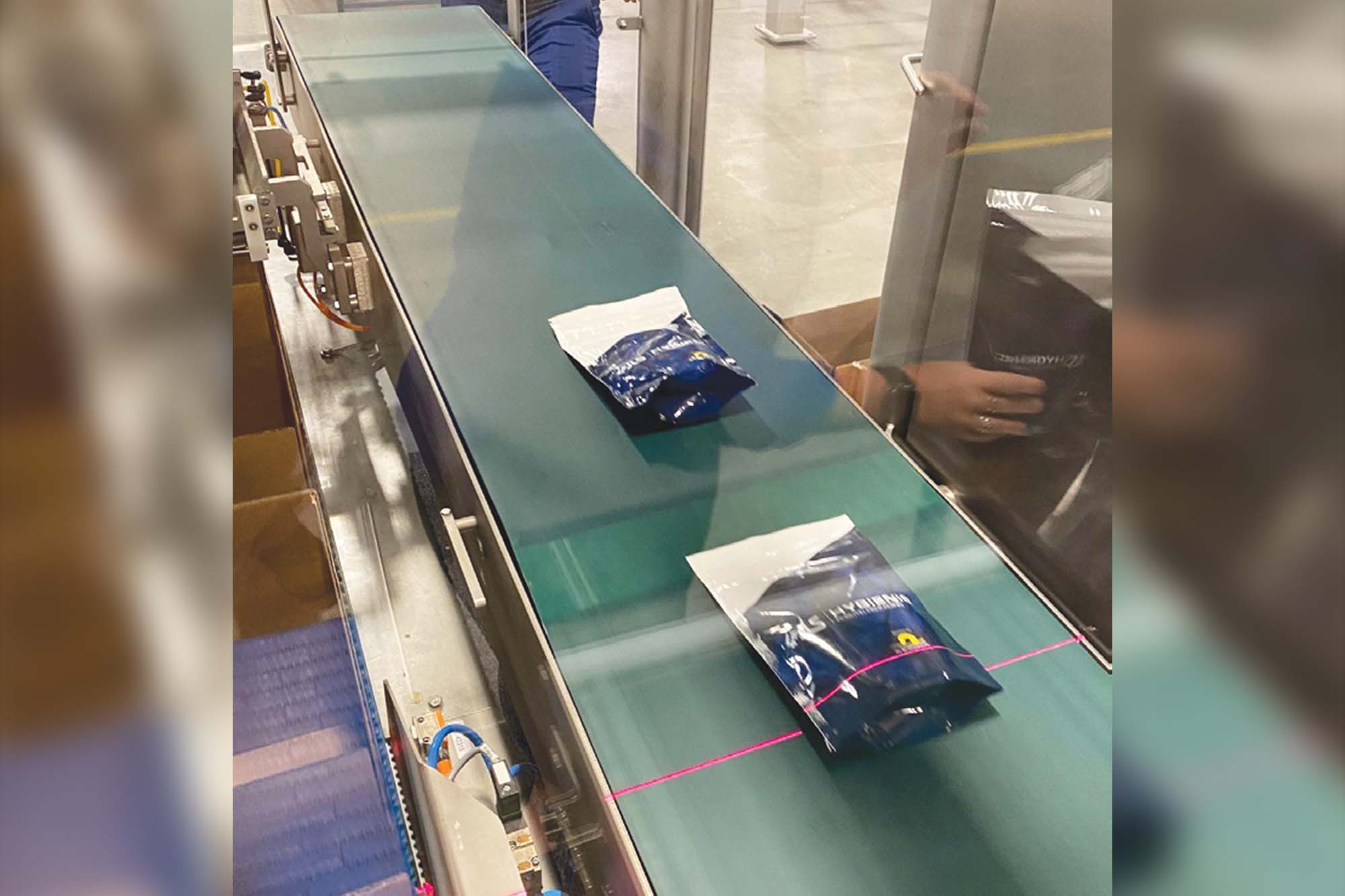

In this application, JLS vision-guided robotic packaging systems are used for inline product dimensioning and sorting of a wide variety of package sizes and types.

The challenge

JLS has provided vision-guided Osprey case packing systems for many years using conventional 2D vision with smart cameras. The systems perform well, but JLS is always looking to improve their product offering, so it conducted a review of alternative technologies and suppliers in 2021. One of the greatest challenges is the range of package colours that need to be handled by individual systems, and the frequency with which the graphics change.

The solution

Implementing 3D vision with LMI’s Gocator 2170 laser profiler brings a fundamental improvement to JLS’ machines. The identification of packages using 3D height information eliminates the problem of trying to identify a package based solely on 2D intensity data used to distinguish the object’s colour from the background. The 3D geometric information provided by the Gocator 2170 sensor is more robust and prevents potential confusion caused by variation in the background.

“JLS selected the LMI Gocator sensor to keep us at the forefront of our industry. It provides solid performance, which allows our customers to consistently meet their production requirements.”

— Craig Hafner, VP Technology, JLS Automation

The result

JLS’s first system was shipped to the customer, and it was commissioned without any issues or even adjustments on-site. The company is also experiencing additional advantages as it implements more Gocator sensors. One of their common systems for chub case packing required changing parts to control the background colour to deal with the wide range of package graphics. This change part is now eliminated. Another system handles stand-up pouches. The profile of these packages obtained with a 2D camera does not provide information on which end of the package is the bottom. The 3D data from the Gocator sensor readily determines this information to ensure that the package is oriented correctly when picked by an industrial robot.

The use of 3D also eliminates the need for external lighting, providing a cost benefit and also improving the sanitary design of machines. Any component that is eliminated does not require cleaning or inspection.

A final advantage of the 3D technology is that it works in physical units (mm) instead of pixels and avoids the need to compensate for lens distortion and parallax effects. This improves the accuracy of their product detection and handling.

Who is LMI Technologies?

As part of the TKH group, LMI Technologies(LMI3D.COM) is focused on the design, development, and delivery of smart 3D technologies, while our sister machine vision companies are dedicated to providing high performance 2D camera-based solutions.

LMI’s sensors improve the quality and efficiency of factory production by providing fast, accurate, reliable inspection solutions that leverage smart 3D technologies.

THE GOCATOR® ADVANTAGE

- Fast profiling speeds up to 5 kHz

- Generates high-resolution dimensional data of packages (length, width, height, volume)

- High repeatability for reliable measurement over time

- Factory pre-calibrated, ready to measure out of the box

- Easy web-based interface for maximum ease of use and operational efficiency

- Onboard software with built-in measurement tools, no third-party software required

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.