LMW in line with contemporary industry requirements paves way for advanced CNC Machines

By OEM Update Editorial July 31, 2023 2:00 pm IST

Indraneel Bhattacharya, Vice President – Sales & Marketing at Laxmi Machine Works, says our focus will include multi-axis, high-speed, and integrated automation machines. And we will prioritise the development of large turning and machining centres catering to the industry’s requirements.

What is your outlook on increasing automation in the machine tools industry?

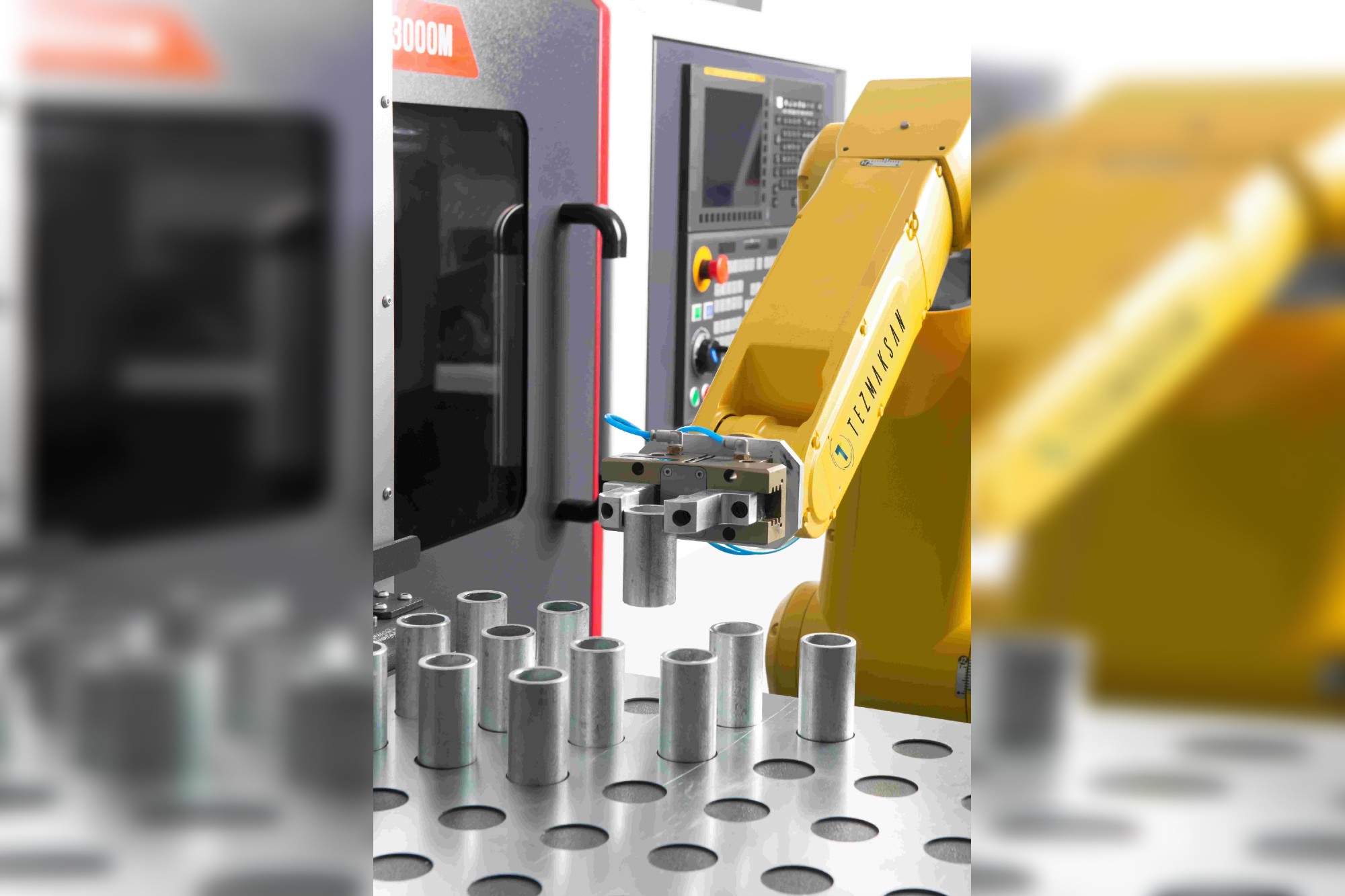

The machine tools industry is set to experience a profound transformation due to the rapid integration of automation. This revolution is expected to yield substantial benefits in terms of productivity, efficiency, and manufacturing capabilities. Automation empowers machine tools to function continuously, delivering tasks with remarkable precision and consistency. Manufacturers can significantly enhance productivity and reduce cycle times by automating processes like workpiece handling, tool changes, and quality inspections, leading to accelerated production rates and improved overall efficiency.

Incorporating automation technologies, such as advanced robotics and CNC systems, introduces a new level of flexibility in machine tool operations. These systems can be easily reprogrammed and reconfigured, allowing seamless adaptation to diverse product specifications and production requirements. Consequently, manufacturers can efficiently produce customised products in smaller batches, effectively meeting the ever-changing demands of their customers.

What are the key highlights of your recently launched product line?

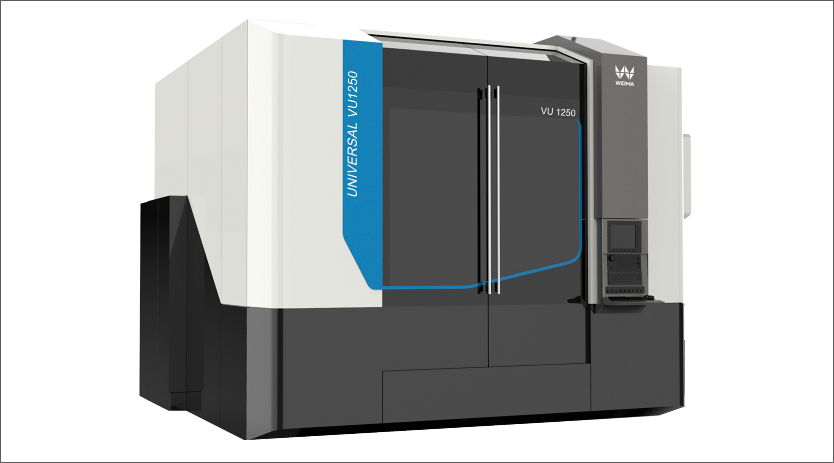

We have recently launched an impressive line-up of new products, featuring a wide range of variants. Among our latest offerings are state-of-the-art machines, including:

- Turning Centers: S Turn 1 & Gigaturn 1

- Vertical Machining Centers: J6 R, J8

- High-speed Drill Tap Center: JD 1

- Horizontal Machining Center: JH500

In addition to these cutting-edge machines, we also offer specialised solutions tailored to specific industries:

LR Series: Designed for the Oil & Gas industry in turning centres.

Smart Minimaster and Smart LT: Specially crafted for the Bearing industry.

LF 20C Twin G: A highly productive machine catering to the needs of the Auto, Pumps, and General Engineering sectors.

How does LMW’s collaborative and customised approach to product development cater to the distinct requirements of various industries?

At LMW, we take great pride in our adaptability and ability to cater to the distinct requirements of diverse industries. We recognise that each sector presents unique challenges, needs, and processes, be it automotive, textiles, aerospace, or any other.

Rather than offering standardised machines, we firmly believe in a collaborative approach with our clients, working closely to grasp their industry-specific pain points and demands. We can better comprehend their exact requirements by closely engaging with our customers and gaining valuable insights into their workflows and production processes.

With this comprehensive understanding, we leverage our vast experience and cutting-edge technology to create customised products that precisely meet their needs. This tailored approach ensures that our solutions seamlessly integrate into their existing operations, resulting in heightened efficiency, productivity, and overall performance.

Whether it is about developing specialised machinery, incorporating specific features, or optimising performance for particular applications, our primary goal is to deliver tailor-made solutions that enable our customers to excel in their respective industries. Through this level of customisation, we empower our customers to maximise operational potential and maintain a competitive edge in their markets.

What key factors make LMW stand out in terms of quality, ease of use, and customer support?

LMW is a prominent industry leader, distinguished by several key factors contributing to its excellence in quality, user-friendliness, and customer support. First and foremost, the company’s commitment to high precision is complemented by the expertise of skilled professionals, producing superior-quality products. Substantial investments in manufacturing facilities and meticulous attention to detail, such as maintaining dust-free and temperature-controlled assembly lines, ensure the utmost accuracy in its offerings. This unwavering dedication to quality is evident across all LMW products. CNC machines are built using precision engineering, top-quality materials, and cutting-edge technology, ensuring outstanding performance and long-lasting reliability.

Secondly, LMW strongly emphasises ease of use, reflected in its user-centric design approach. The company prioritises intuitive interfaces, ergonomic features, and user-friendly controls, making its machines accessible and straightforward, even for less-experienced operators. This focus on user-friendliness translates to enhanced productivity and reduced downtime, benefiting customers across diverse industries.

Thirdly, LMW’s unparalleled dedication to customer support sets it apart. The company places great importance on understanding and addressing its customers’ needs. It offers comprehensive after-sales support, including training, technical assistance, and prompt maintenance services. This commitment ensures that customers can maximise the performance of their CNC machines, minimise disruptions, and maintain seamless operations.

Furthermore, LMW’s customer-centric approach goes beyond problem-solving. The company actively seeks customer feedback, using it to improve its products and services continuously. This open and collaborative communication fosters strong relationships and builds trust, making customers feel valued and respected.

Lastly, LMW’s commitment to innovation is pivotal in upholding its reputation. The company invests in indigenous research and development, enabling it to stay at the forefront of the market by offering cutting-edge solutions that address emerging industry challenges and trends.

How do LMW’s CNC machines deliver a competitive advantage to automobile and general engineering customers?

LMW’s CNC machines provide significant advantages to automobile and general engineering customers, offering enhanced precision, heightened productivity, superior quality, versatility, cost-effectiveness, advanced technology, energy efficiency, and comprehensive after-sales support. These machines facilitate accelerated production, tighter tolerances, and the ability to work with various materials, empowering customers to gain a competitive edge in their manufacturing operations.

Can you provide insights into LMW’s indigenous research capabilities and its role in developing advanced CNC machines?

LMW has established itself as a leading machine tool industry player and has made substantial investments in indigenous research capabilities. The company’s unwavering research and development (R&D) focus has been pivotal in creating cutting-edge CNC machines. LMW has established state-of-the-art research facilities supported by a team of skilled engineers and researchers by emphasising innovation and continuous improvement. Leveraging advanced software for design and analysis, the R&D team conducts in-depth studies and experiments, resulting in CNC machines surpassing performance, precision, and efficiency expectations.

Through in-depth studies and cutting-edge technology adoption, LMW has developed CNC machines that push the boundaries of performance, precision, and efficiency. LMW integrates the latest advancements and customises solutions to cater to the diverse needs of its customers. This commitment to innovation, quality, and customer satisfaction is evident in their indigenous research capabilities. The company’s R&D endeavours play a crucial role in developing advanced CNC machines that effectively address the ever-evolving demands of the industry, contributing significantly to its growth and continued success.

What are your future expansion plans to meet the business demand of the industry?

Our future expansion plans are aligned with a deep understanding of our customers’ distinct needs and fulfilling them accordingly. To meet the growing demands of the industry, our focus will be on developing new products infused with cutting-edge technology. Our key areas of concentration will include multi-axes machines, high-speed machines, and machines with integrated automation. Moreover, we will prioritise the development of large turning and machining centres catering to the industry’s requirements.

In line with the industry’s stringent quality standards, we will prioritise machines with exceptional accuracy and precision. By aligning our expansion strategy with the specific needs of our customers, we aim to maintain our leading position in the industry and continue delivering innovative solutions that enhance efficiency and productivity for our valued clients.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.