Talegaon facility expansion implies a commitment to sustainable manufacturing

By OEM Update Editorial January 31, 2024 7:32 pm IST

Regarding the expansion of the manufacturing facility, Kamlesh Panchal, General Manager, Atlas Copco India, states the company is doubling its factory size in Talegaon, prioritising sustainability, energy efficiency, and Lean principles for eco-friendly products.

What sustainability features are integrated into your new green manufacturing facility?

Atlas Copco has strategically decided to expand its production capacity in response to the growing local and export demand from India. We have already commenced construction on a new factory located in Talegaon, which will nearly double our current facility’s size. Sustainability and environmental considerations are at the forefront of our efforts throughout the construction process.

Once the factory is operational, we are committed to sourcing 80 percent of our energy needs from solar power, emphasizing our dedication to sustainability. Despite our relatively low water consumption in manufacturing, we plan to implement water harvesting practices, focusing on rainwater harvesting, which will significantly reduce our environmental footprint.

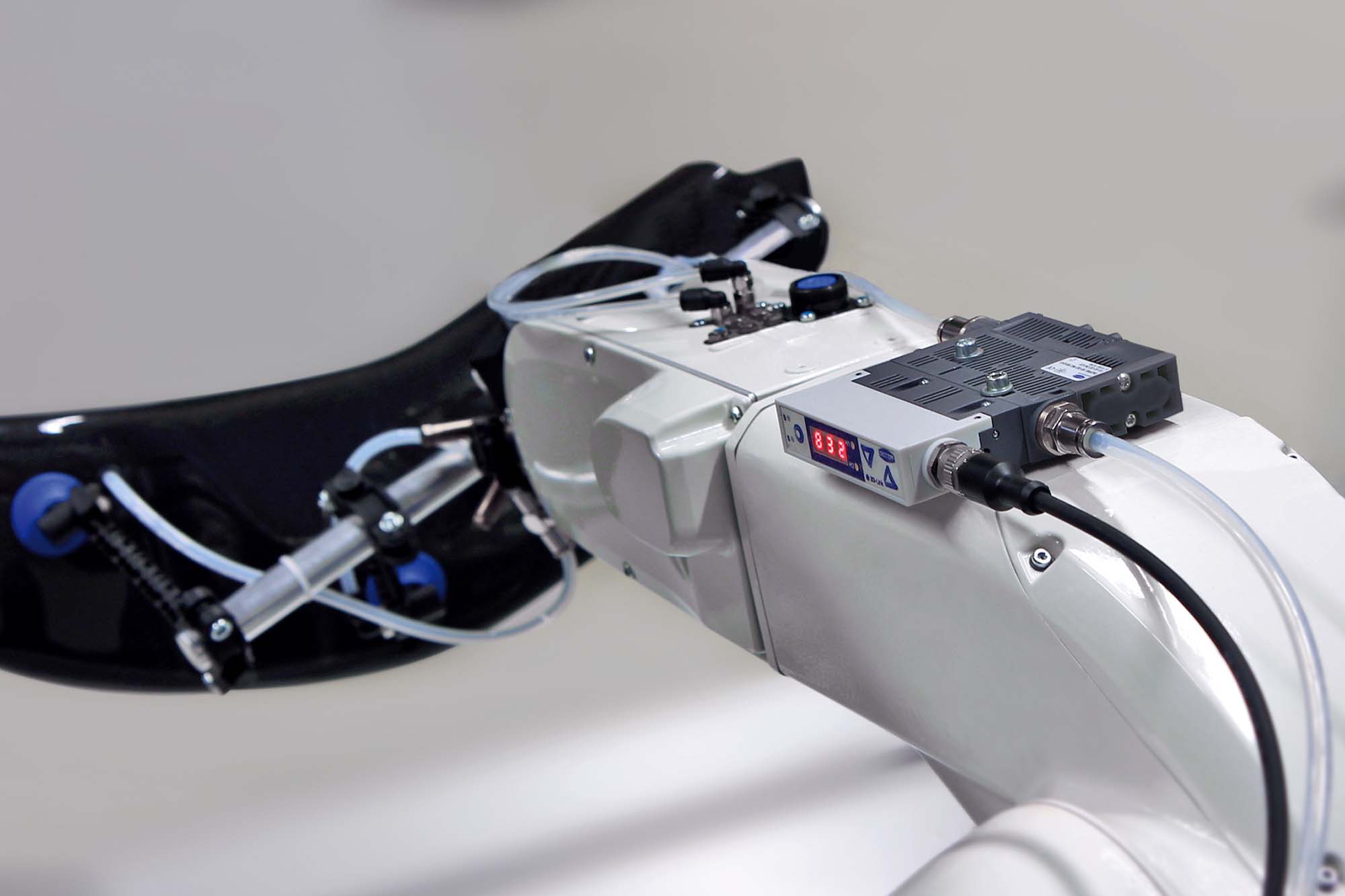

Additionally, we are implementing Lean principles to optimise our operations, resulting in energy-efficient products that align with Atlas Copco’s core commitment to innovation. These innovative products will benefit our customers by enhancing their efficiency and productivity and contribute to their sustainability goals. We deliver value and tailored solutions to ensure our customers are more efficient, productive, and environmentally conscious.

What kind of investment have you made in this project?

Our investment in the Talegaon facility amounts to 140 crores, and from a capacity point of view, it would be driven by the growing demand in the Indian export market. This aligns with the government’s “Make in India” initiatives, and the plant will contribute significantly to this effort.

Will the new recruitment of 200 employees be local, or is there a different plan for sourcing this workforce?

Indeed, our priority for the Talegaon facility is to tap into the local talent pool. We aim to hire from the local community and in addition to our existing workforce, creating around 200 new job opportunities in the district. Atlas Copco is committed to nurturing and grooming young talent, a key focus of our talent acquisition and development initiatives.How is Atlas Copco using Industry 4.0 and digitalisation to improve product efficiency and performance?

As we establish new facilities, we remain focused on industry trends. This new facility will be highly digitalized, aligning with Atlas Copco’s commitment to providing sustainable solutions. It will utilize our own brand tools, which enhance energy and product efficiency. We aim to continually boost productivity and efficiency by integrating these technologies.

How is Atlas Copco adapting its product offerings and strategies to address the growing demand for sustainable energy solutions?

Atlas Copco is actively involved in various sectors, with a significant focus on environmental improvement. We’re witnessing a prominent shift towards environmental consciousness, particularly in converting vehicles to CNG (Compressed Natural Gas), where our products play a vital role. Atlas Copco manufactures CNG-related products and is heavily involved in biogas and hydrogen initiatives. Given the environmental concerns associated with fossil fuels and carbon dioxide emissions, we foresee a substantial transition towards green energy-driven industries in the future market. Our commitment is to safeguard the environment for future generations.

When this one comes into operational mode, what would be the status of the current Dapodi plants?

Indeed, our growth has outpaced the capacity of our current factory. Therefore, we are in the process of relocating our production facility to a state-of-the-art, larger facility. Additionally, due to our rapid expansion, our existing plant will serve as the central hub, consolidating our scattered customer centres and offices. This site will become the primary office for Atlas Copco. We operate a Global Engineering Centre in India with over 1000 employees. By centralizing our offices, there will be an opportunity to accommodate them as well.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.