Human-robot collaboration: The future of robotics

By OEM Update Editorial May 14, 2018 12:58 pm IST

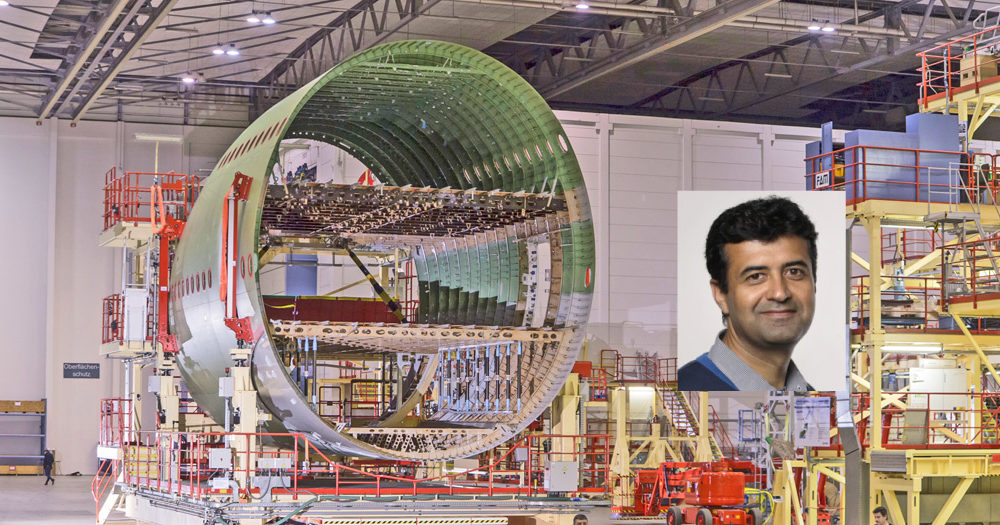

radeep Shoran, AGM-Marketing, KUKA Robotics India explains how robotics is transforming the shop-floor.

Greater customisation, more product variants, breakaway from rigid mass production towards personalised products that the customer can configure for himself in the digital world at a PC – these developments are influencing production processes. This is because production will need to become ever more flexible in this world of customised products. The outcome of this development could be extremely versatile production on an industrial scale and networked throughout the entire process chain. In such a factory of the future, mobile robot systems ensure that it is not necessary to integrate each new work step into the existing production lines. In conjunction with autonomously navigating platforms, robots ‘learn how to walk’ and move flexibly to the different production sections, instead of standing rigidly behind safety fences. It is then no longer necessary to transport the workpiece to the robot; instead, the robot moves directly to the workpiece or to the machine tools.

People are divided on what the future will look like with robots in the public domain. While some see robots as humanoid creatures that steal jobs, many find them fascinating and dream of a future with robots.

KUKA have a very clear vision: robots should assist people, not the other way around. Robots can help people with their work, relieving them of unpleasant or non-ergonomic tasks. The tasks carried out by people should preferably be limited to those requiring human skills such as the ability to learn, learning from experience, sensory perception, creativity, improvisation, etc. Robots can complement these human virtues with power, repeatability, speed and quality. Smartphones and PCs are part of everyday life for all.

At KUKA, human-robot collaboration (HRC) also means responsibility. People are always the central focus – robots are there to help people and must never endanger them. To do so, robots must comply with new safety requirements. There are of course various ways to deal with these requirements. KUKA draws a distinction between safety functions in place to protect people when they are working with a robot and functions that make the robot itself safe.

How safe is the area around the robot? What tools does it use? These are questions have to be addressed. It is not right to leave the safety of a robot system up to the integrators or users – the customers. KUKA is not satisfied until the robot is safe in its particular application. The company thinks about how close the human comes to the robot because, broadly speaking, and almost all robots are capable of HRC in one way or another. There are four variants:

• The robot stops when the safety gate to the robot is opened. All that is needed for this variant is a safe input (a safety relay if necessary) that stops the robot when somebody enters the area.

• If the robot is to be manually operated, a three-position enabling switch and safe velocity monitoring is required in addition to the safe input. (In some cases, safe orientation monitoring may also be required.)

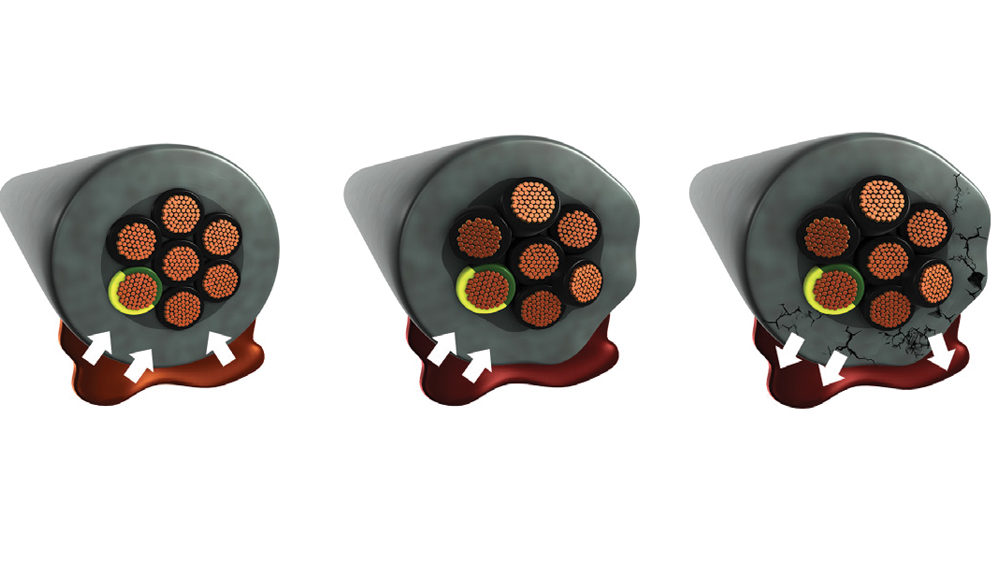

• If the use of one safe sensor can (just as safely) determine the location of the person, the robot velocity can be reduced according to the distance between the person and the robot to ensure that the robot is always at standstill when the person reaches it. For this variant, the robot needs the ‘safe velocity monitoring’ safety function and a safe input for the emergency stop button. The basis for all current HRC robot systems is collision avoidance.

• The ultimate challenge and the true essence of human-machine collaboration is collision control (power and force limitation). This involves the robot being able to interact with the person – the person can touch the robot, guide it, and even collide with it. Using functions such as safe collision detection or safe force monitoring, it must then be ensured that forces and pressures do not exceed defined, safe limits in the event of a collision, regardless of the operation situation. Shortly spoken, that the robot does not hurt the human.

Once the robot’s application has been clarified, the question now is whether the robot provides the required safety functions. KUKA implements the following functions, for example:

• Safe collision detection

• Safe force monitoring

• Safe workspaces and protected spaces

• Safe position monitoring

• Safe velocity monitoring

Pradeep Shoran,

AGM-Marketing,

KUKA Robotics India Pvt Ltd

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.