Shot blasting: Eco-friendly option for corrosion removal and surface

By OEM Update Editorial July 12, 2018 6:01 pm IST

Patel Furnace & Forging is one of the leading manufacturers, distributors, and exporters of shot blasting machinery, sand blasting machines, and shot peening equipment.

Airless shot blasting machine | Surface preparation equipment | Blast room plant

Shot blasting is a method used to clean and induce strength (shot peening) or polish metal surface. It is used in almost every industry that uses metal, including aerospace, automotive, construction, foundry, shipbuilding, rail, and many others.

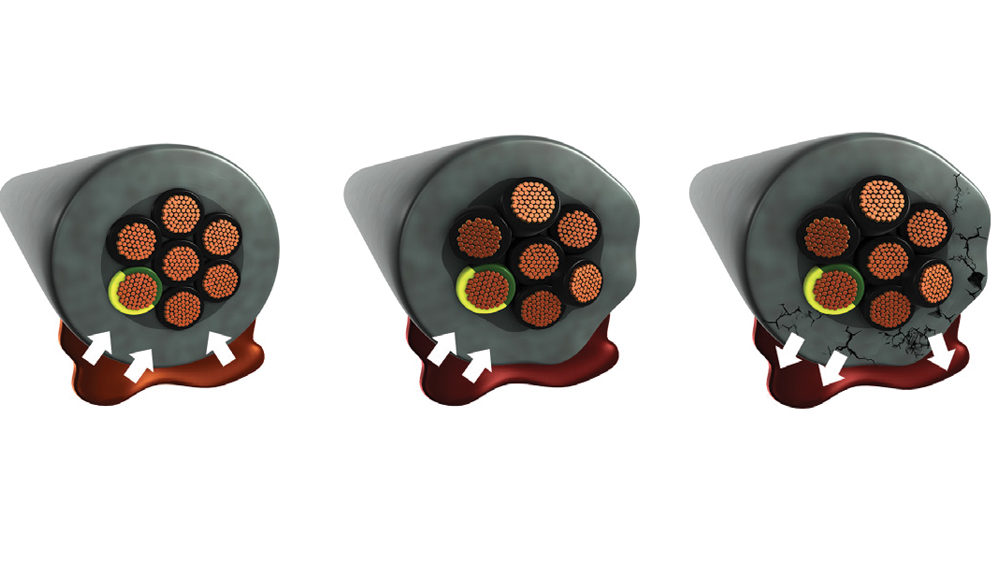

Shot blasting process has become an integral part of steel structure and metal building industry. Shot blasting provides 2 vital benefits for steel protection. Firstly, it removes all rust, mill scale, and corrosion; thus, eliminating moisture which is almost and always entrapped beneath these corrosion products. Secondly, it provides ideal surface finish (SSPC – 10 | SA 2.5) for securing a continuous and effective bond between the steel surface and coat.

Advantages of shot blasting

Removing corrosion

• Shot blasting can remove all forms of rust and corrosive materials from the metal surface, while leaving the base of the product unaffected

• Typical corrosive builds include rust, mill scale, chemical stains, chipped or faded paint, and heat treatment scale

Surface preparation

• Shot blasting is the most efficient and the most effective process to prepare a metal surface prior to painting or coating

• High blast pattern accuracy

• Much better bond between blasted surface and the protective coating

• Aids in revealing any surface defects or errors

• Increases the lifespan and the endurance of future coatings

The environment

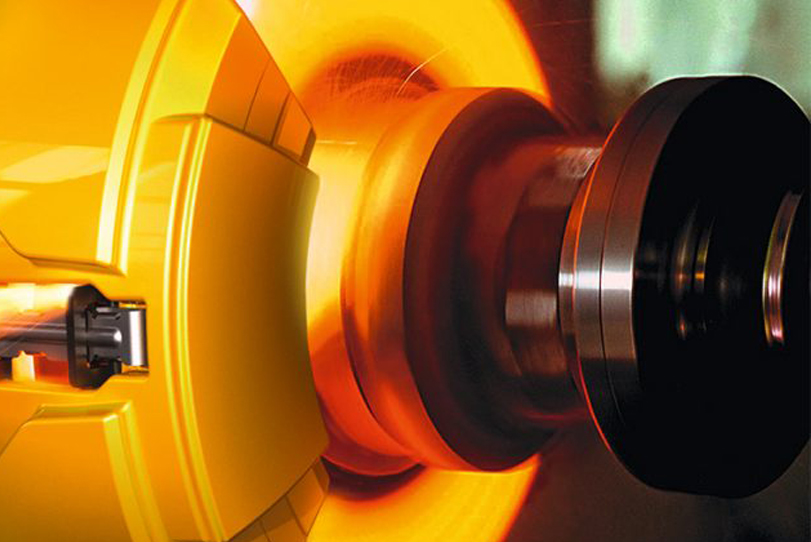

Wheel blasting (Airless shot blasting)In wheel blasting, the abrasive media is propelled on the workpiece to be blast clean; this is done by rotating a turbine wheel and directly converting electric motor energy into kinetic energy. It is categorised as an airless blasting operation because there is no use of air, liquid or gas to propel the abrasive media. A wheel machine is a high-power, high-efficiency blasting operation with recyclable abrasive (typically steel or stainless steel shot, cut wire, grit, or similarly sized pellets).

Air blasting (Pneumatic shot blasting / Air operated shot blasting)

In air blast machines, the abrasive media is propelled with the help of compressed air pressure. A blast room is a complete air blast system which includes four main systems, the blasting chamber, the abrasive blasting pot or hopper, the dust collector, and abrasive recycling system. The recycling systems ranges from manual sweeping and shoveling the abrasive back into the blast pot to full reclaim floors that convey the abrasive pneumatically or mechanically to a device that cleans the abrasive prior to recycling.

Authored by:

Nilesh Vaja

Manager Sales,

Patel Furnace & Forging Pvt Ltd (Shot Blasting Division)

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.