From imports to independence, Godrej is building a resilient, self-reliant supply chain

By Staff Report June 5, 2025 6:43 pm IST

Godrej has been a household name for more than a century now. But with shifting geopolitics and growing global demand, Zurvan Marolia says Godrej Enterprises Group is also redefining its supply resilience and advancing localisation to raise India’s industrial stature through sustainable exports and world-class manufacturing standards.

How has globalisation influenced your operations, and what challenges does Godrej face in borderless trade?

At Godrej Enterprises Group, we have always stood for Safety, Sustainability and Self-Reliance. Our 128-year-old organisation has taken root in the movement of self-reliance, and we have been adapting to these challenging industry dynamics by implementing comprehensive supply chain resilience strategies. We remain committed to sustainability across our operations, balancing economic resilience with environmental responsibility.

To that end, GEG’s primary focus has been on meeting the growing demands of our domestic markets, which are the fastest growing globally. GEG is mindful of the need to “Make in India & Supply to the World” today; to this end, we make products to international standards and have stepped up our efforts to enhance the share of exports in our top line.

The various geopolitical developments over the last decades gave us good reason to cut down on imports and develop local sources for import substitution, which aligns with the roots and the National call for “Atmanirbhar Bharat” and “Viksit Bharat.”

Challenges in borderless trade range from regulatory and compliance issues to financial risks such as currency fluctuations. These are at the top of our minds as we see that global supply chains are currently being disrupted and buffeted by tariff storms. This leads to new supply chains that could benefit Indian manufacturing, particularly organisations that have reduced dependence on imports.

Cybersecurity and data privacy are potentially challenging areas, and we have been working over the years to build rigour and operational discipline to remain protected and ensure compliance with the highest data privacy standards.

What strategies is Godrej adopting to improve India’s brand image and retell the Indian story to the world?

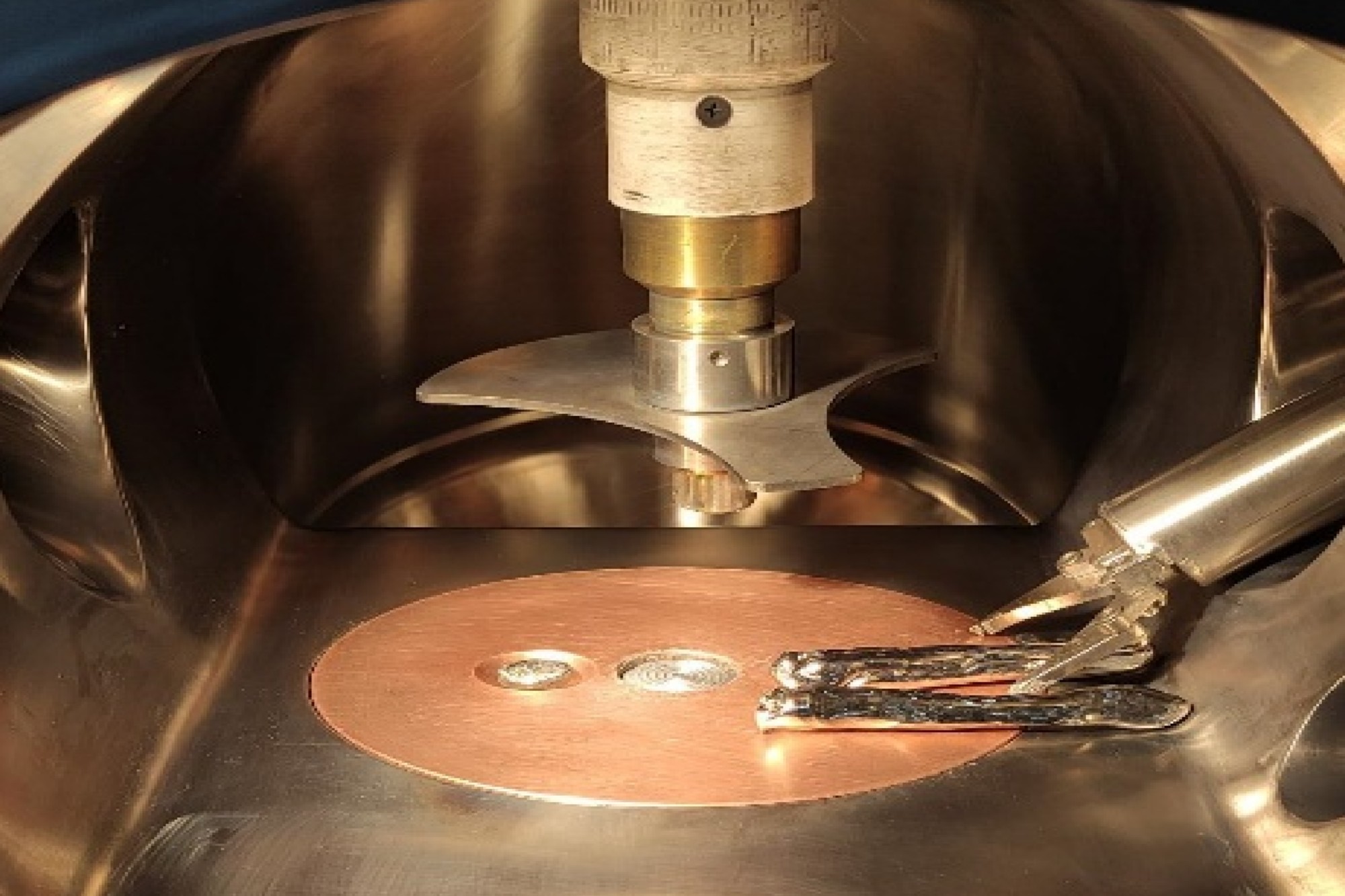

At Godrej Enterprises Group, we recognise our role in shaping global perceptions of Indian industry and actively contribute to redefining India’s brand image internationally. We are leveraging our innovation and manufacturing excellence legacy to showcase Indian capabilities beyond traditional sectors. Through consistent quality and reliability in our exports across diverse markets, we demonstrate that Indian companies can compete at premium global standards. We highlight India’s unique strengths in our international engagements, particularly emphasising our nation’s technological capabilities combined with sustainable approaches. For instance, the process equipment business of Godrej Enterprises Group contributed to the green hydrogen space by dispatching heat exchangers to a Green Hydrogen project in the Middle East. The project is one of the world’s largest commercial-scale green hydrogen production facilities.

What role do global standards play in Godrej’s manufacturing processes, and how do they contribute to quality and competitiveness in international markets?

Global standards play a fundamental role in our manufacturing processes and are critical to international competitiveness. We view adherence to recognised global standards as a strategic tool that enhances our operational excellence and market acceptance worldwide. We ensure our manufacturing processes meet the highest international benchmarks by integrating standards like ISO 9001 for quality management, ISO 14001 for environmental management, and industry-specific certifications across our diverse business portfolio (e.g. AS9100, NADCAP for Aerospace). These standards provide structured frameworks to maintain consistency across our global operations while enabling continuous improvement through standardised measurement protocols.

Beyond compliance, we leverage global standards as platforms for innovation by staying engaged with evolving international requirements that often anticipate market trends and consumer expectations. This forward-looking approach allows us to integrate emerging sustainability parameters, safety considerations, and technological advancements into our product development cycles.

How have supply chain disruptions (pandemic, semiconductor shortages, and logistics crises) changed Godrej’s supply chain strategies?

Agility and Risk Management are at the heart of our approach to process management. Our SBUs remain vigilant to changes in external developments and respond with timely changes to ensure the uninterrupted flow of inward and outward movements in the supply chain.

For example, we have worked towards shortening our supply chain by reviewing the locations of our intermediate warehouses and opting for direct deliveries where economically viable. This has the dual benefits of cutting costs, reducing lead times, and making the supply chain more robust and resilient.

Changes in the geopolitical climate prompted a focus on developing import substitutes and reexamining particularly vulnerable sources, thereby diversifying the sourcing locations to ensure uninterrupted supplies. Similarly, the current tariff turbulence will open up new opportunities to review and redefine supply chains, as those adversely affected will be willing to renegotiate prices to protect their business interests.

The development of local sources of supply for import substitution has been prioritised as a route to insulating our businesses from global supply chain disruptions.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.