Hydraulic filters for extended machinery operative life

By OEM Update Editorial February 7, 2024 7:05 pm IST

Atos F+ microfiber filters contribute to the total system approach to fluid cleaning to prevent machine downtime and related issues, improve energy efficiency, and focus on eco-sustainability.

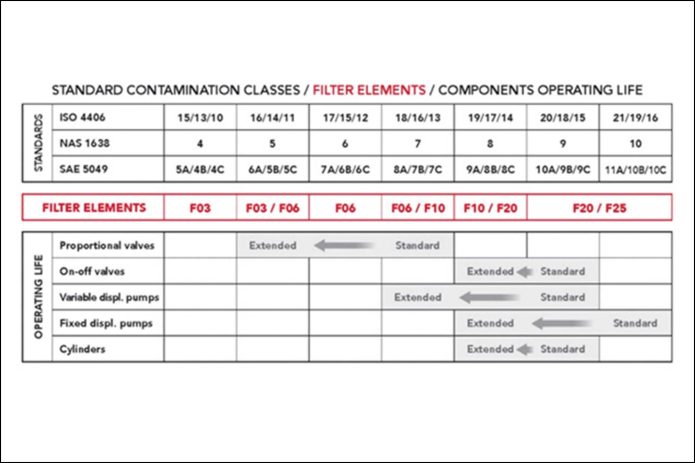

A comprehensive approach to fluid cleaning involves accurately analysing the maximum acceptable contamination class. This is achieved by selecting appropriate hydraulic filters to extend component life, improve production times, minimise downtime and maintenance costs, and reduce waste oil disposal costs with associated environmental benefits. Microfiber filter elements with absolute filtration capacity can reduce contamination levels to very low values compatible with the most sensitive components.

Neglecting filtration care leads to annual financial losses

Analyses conducted in various industrial sectors confirm that an accurate selection of hydraulic filters and filtration methods may reduce costs for machine downtime, component repairs, and fluid disposal by about 50% per year compared to systems without specific filtration care. This aspect is even more important for machines with higher performance levels and, therefore, more sophisticated components used in the hydraulic circuit.

Fluid contamination

Solid contamination of hydraulic fluid is a major cause of financial loss, as it leads to erosion and sticking phenomena within the internal parts of pumps, valves, and actuators, thereby harming the component’s lifespan.

While solid contamination cannot be eliminated entirely, it can be consistently reduced through hydraulic filters. This ensures that its value remains equal to or better than the maximum contamination level tolerated by the most sensitive component present in the system.

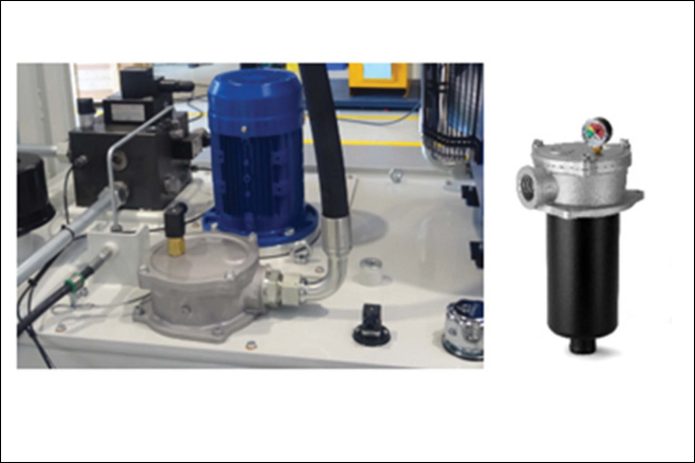

The return line filter is a cost-effective solution that ensures the cleanliness of fluid returning to the tank. It is often used in systems where no sensitive components are present. This filter removes contaminants released by the system during its operation before the fluid returns to the tank. Return filters typically operate at low pressure (maximum 8-10 bar) and are commonly directly flanged on the tank (tank-top mounting).

The in-line filter is highly recommended for systems equipped with proportional valves as it protects all hydraulic components downstream of the filter and ensures a high level of cleanliness for the fluid circulating within the hydraulic system. In-line filters are designed to withstand high pressures (usually 350 to 420 bar). They can be installed at the pump outlet or directly flanged on manifolds, thereby saving on pipes and fittings and reducing overall dimensions.

Combining in-line + return filters is used to obtain greater benefits and reduce the contamination level.

Off-line filtration provides continuous cleaning of the fluid in the tank. It is particularly useful in cases of wide changes in system flow, systems operating for long periods with no flow, or to enhance fluid cleanliness in systems already equipped with in-line filters. Using a heat exchanger to combine filtration and temperature control is common.Filter elements

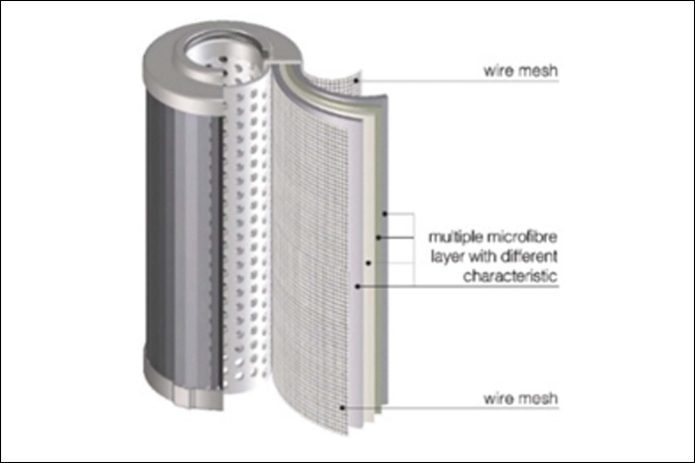

They are the ‘core’ of the filter, as the quality of fluid cleanliness depends on their characteristics. Microfiber filter elements offer the best performance in terms of filtration rating, which can reach very accurate values up to 3 µm, and efficiency up to 99.9%. Therefore, they are recommended for all hydraulic systems.

ATOS F+ Microfibre filter elements

ATOS filtration Plus microfiber filter elements combine different materials and layers specifically arranged to achieve optimal results in high efficiency, high dirt holding capacity, and low-pressure drops.

High Efficiency

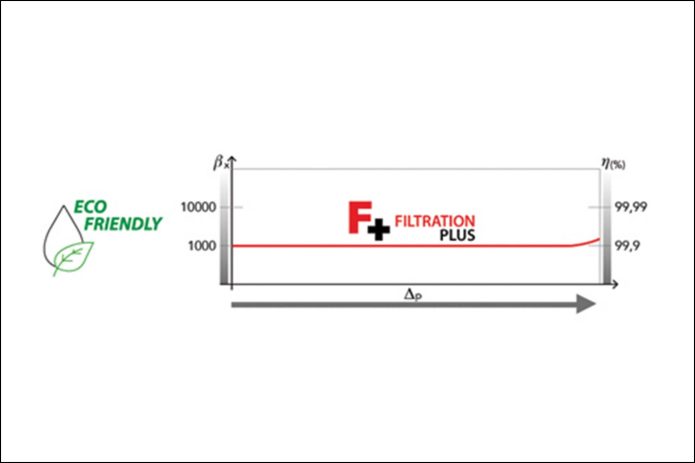

“Traditional filter elements decrease efficiency as the pressure difference (∆p) across the filter increases due to accumulated contaminants. However, thanks to their special media pack structure, ATOS Filtration Plus elements ensure excellent performance in terms of efficiency (Beta Ratio > 1,000) and stability against pressure drop increases, maintaining consistent performance throughout the entire life of the filter element. Furthermore, the reduced pressure drops enable the selection of a smaller filter for the same application.”

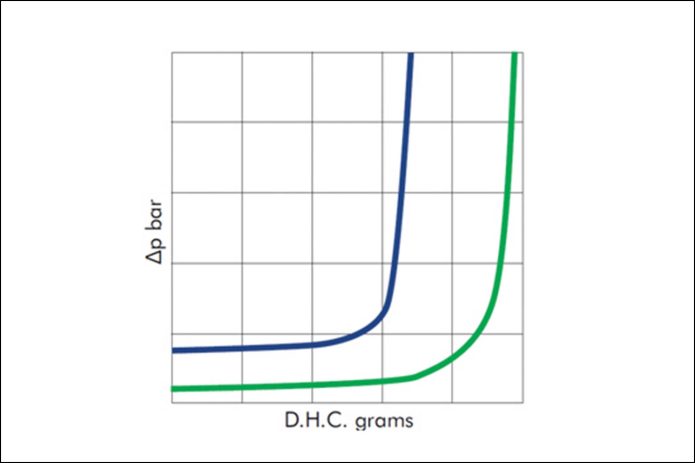

“The increased Dirt Holding Capacity (D.H.C) of F+ filter elements allows them to retain more contaminants before reaching the maximum clogging condition. This extends the average life of the filter element, thereby reducing maintenance costs and minimising the environmental impact associated with cartridge disposal.”

Atos beholds confidence in filtration. Plus, microfiber filter elements are such that the warranty period for all ATOS products in systems equipped with ATOS Hydraulic filters is doubled.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.