KCL boosts EV electronics with new line

By Staff Report July 1, 2025 5:56 pm IST

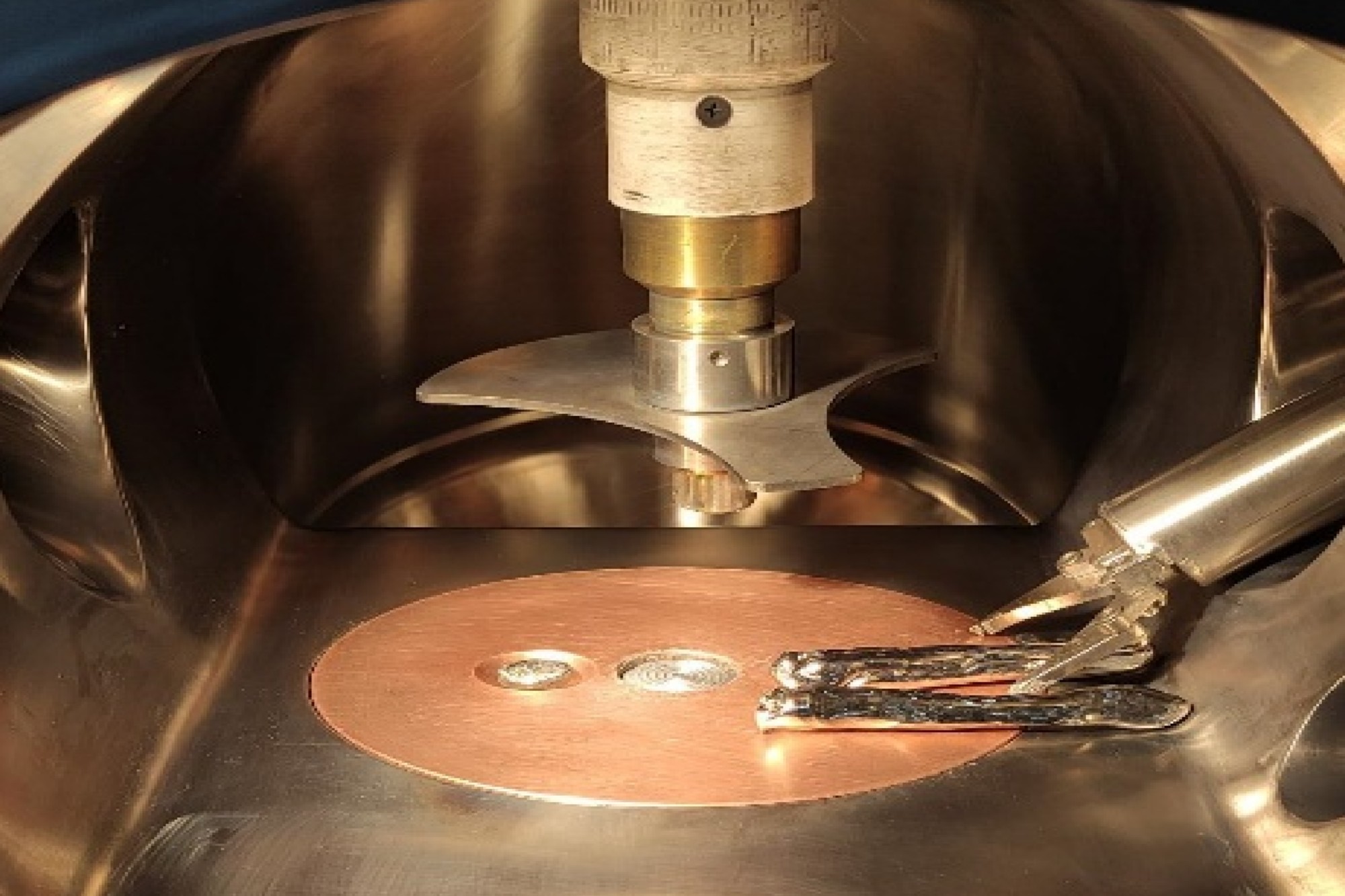

Kinetic Communications Limited (KCL) has inaugurated a fully automated, Industry 4.0-ready controller manufacturing line at its Pune facility. The advanced line will boost EV electronics production with high-speed, precision assembly, supporting smart features and global quality standards.

Kinetic Communications Limited (KCL), a leading provider of advanced electronic manufacturing solutions, has launched a cutting-edge, fully automated controller manufacturing line at its Pune plant. The new line was launched by Padmashri Dr Arun Firodia, Chairman of the Kinetic Group; Deepak Shikarpur, Director of KCL; and Ajinkya Firodia, Vice Chairman of the Kinetic Group.

The facility blends Surface Mount Technology (SMT), Human Machine Interface (HMI), and Programmable Logic Controller (PLC) systems to provide real-time process control, seamless traceability, and little user involvement, reducing mistakes and increasing throughput.

At its core, the factory manufactures Motor Controller Units (MCUs), which manage the battery-motor interaction and provide functions like hill-hold aid, cruise control, regenerative braking, coasting, and diagnostics. It creates power and driver board assemblies as well as complete controller box assemblies using high-speed SMT lines that can place up to 40,000 components per hour with 100% verification. To fulfil endurance and quality criteria, final assemblies are flashed with software, tested for IP67 leaks, and validated functionally.

With a capacity of 300 units each shift and a potential yearly output of 180,000 units across two shifts, the plant is built for rapid expansion. Alternate lines and contingency mechanisms ensure that deliveries run smoothly even if market demands change.

Ajinkya Firodia, Vice Chairman, Kinetic Group, “The new completely automated controller line is a big step towards Industry 4.0-driven smart production. It’s a high-throughput, precision-engineered facility that adds intelligence, speed, and scalability to our processes. Every stage is data-driven and benchmarked to global quality standards. This is more than a technological advancement; it is a declaration of our dedication to innovation and operational excellence.”

Deepak Shikarpur, Director of KCL, stated, “This facility exemplifies modern Make in India practices. With its automation, precision, and capacity to produce smart, feature-rich motor controller modules, it puts India on the global map for next-generation EV electronics production.”

Quality assurance techniques include 3D Solder Paste Inspection (SPI), Automated Optical Inspection (AOI), In-Circuit Testing (ICT), lead-free dualwave soldering, Poka Yoke mechanisms, End-of-Line (EOL) testing, and Pre-Dispatch Inspection (PDI). Incoming Quality Control (IQC) conforms to JESD22 standards, and suppliers must provide Certificates of Conformance (CoC) to demonstrate RoHS and REACH compliance.

With this expansion, KCL intends to achieve zero PPM faults, increased productivity, superior quality, and increased customer satisfaction through automation and process efficiency.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.