New AMAZEMET service breaks barriers in experimental alloy production

By Staff Report July 18, 2025 5:02 pm IST

AMAZEMET introduces a new atomisation service enabling affordable, small-batch production of custom metal powders for experimental alloy development.

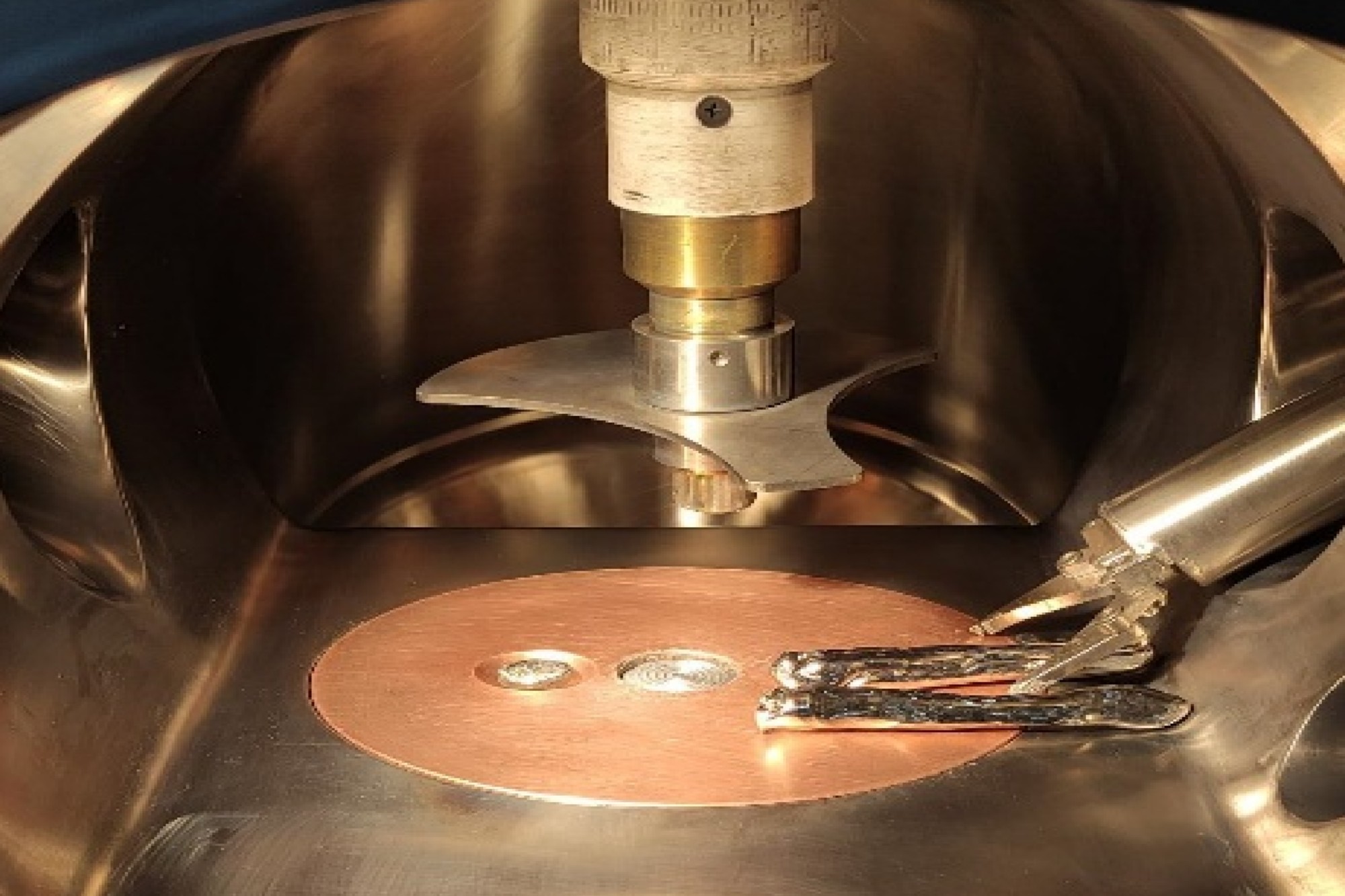

AMAZEMET, a firm dedicated to research in materials science and additive manufacturing, has officially launched its new Atomisation Service. This on-demand service allows researchers to generate small batches of high-quality, bespoke metal powders at a low cost and with excellent efficiency.

Dr. Łukasz Żrodowski, CEO of AMAZEMET, stated, “We identified an obvious hurdle in material innovation. Researchers with excellent ideas were hampered by expensive costs and the impossibility of getting small, experimental batches of high-quality spherical powders. ” Our new service removes that barrier, enabling faster discovery and development.”

Powder metallurgy and additive manufacturing (AM) require powders with certain qualities, such as high sphericity, good flowability, narrow particle size distribution, minimal satellites, and low oxygen concentration. Traditional gas or plasma atomisation techniques are best suited for large-scale manufacturing, needing feedstock quantities in the tens of kilograms—making them inefficient and costly for small-scale research, particularly when utilising high-value elements such as scandium, hafnium, or rhenium.

AMAZEMET’s ultrasonic atomisation technology tackles this issue by providing a more efficient and accessible method of generating experimental powders.

- Low entry threshold with pricing starting from €1,000 and a minimum material requirement of 50 grams.

- High yield with up to 80% of feedstock converted into powder within the target size range (e.g., 15–63 µm).

- Material versatility, including reactive and high-temperature materials such as magnesium, titanium, gadolinium, and refractory alloys.

- Recycling capability through Powder2Powder™ technology for re-atomising used or off-spec powders and direct atomisation of scrap materials without preprocessing.

- Pre-alloying support with in-house arc-melting to ensure precise composition before atomisation.

- Multi-material processing allows different materials to be processed in a single order at no additional cost.

AMAZEMET also values research collaboration, disclosing all important processing parameters with clients. Its staff of materials science professionals, including PhDs and PhD students, is ready to help integrate the findings into scholarly papers.

Ultrasonic atomisation is a critical enabler in speeding alloy formation for AM. AMAZEMET’s service gives researchers faster access to personalised, high-quality spherical powders required for next-generation materials innovation.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.