A glimpse into a women-led powerhouse in rubber manufacturing

By Staff Report August 8, 2025 5:06 pm IST

Shriram Rubber Products PVT. LTD was established in 1975 by Shri Subhash Kotasthane. The company currently operates two plants in MIDC Bhosari, a prominent industrial hub in Pune. Notably, all Board Directors are women, consisting of the founder’s three daughters. Shriram Rubber Products specialises in manufacturing customised and critical rubber products according to customers’ drawings and material specifications. With partnerships with global organisations and over 40% of its production exported, Shriram Rubber is a preferred supplier of critical rubber components.

When dinner table conversations revolve around the business and children grow up visiting the factory, the foundation of a family-run business strengthens its roots. Prajakta, Priya, and Preeti are no exception to this. Nurtured to understand the nuances of Shriram Rubber Products Pvt. Ltd. throughout their learning curve, the sisters represent the second generation of leadership. They are responsible for expanding the business and keeping it afloat.

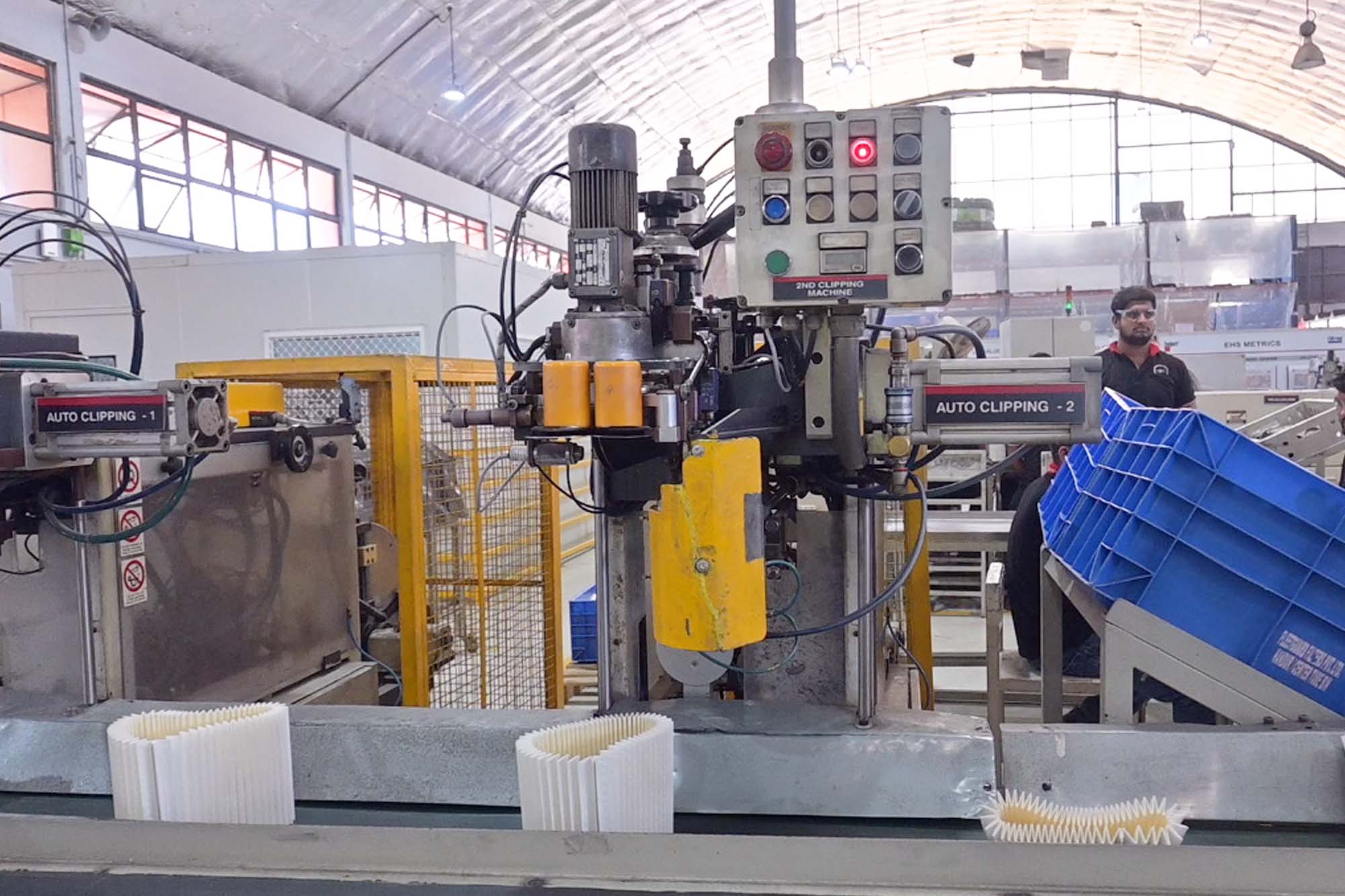

OEM Update visited their factory in Pune, where we witnessed the manpower in action. More than a hundred employees operated the facility. The entire process, from grinding and shaping to packaging and assembly lines, was driven by human effort and seamless coordination.

Product development process

When it comes to production, the company follows a collaborative approach while working with OEMs for customised rubber products. The development cycle is initiated once the customer shares their engineering drawings and material specifications. This is followed by a detailed Technical Feasibility Review, during which the team actively engages with the customer’s engineering department to fully understand the specific application, performance expectations, environmental conditions, and any regulatory requirements.

The company formulates a customised rubber compound, essentially a recipe that includes a combination of ingredients tailored to meet the required physical properties, such as hardness, tensile strength, and modulus, based on technical input. Where necessary, the formulation also accounts for chemical, oil/fuel, and ozone resistance.

Once the compound is finalised, prototype samples are produced using vacuum compression moulding, and these undergo thorough inspection and testing. The facility houses a fully equipped Quality Control (QC) Laboratory, staffed with trained personnel and capable of conducting both physical and chemical testing of rubber compounds as per ASTM, DIN, and IS standards. In addition, a range of precision measuring instruments is used to verify dimensional accuracy.

To ensure consistency and customer satisfaction, the company adheres to well-established procedures and standards, including APQP (Advanced Product Quality Planning) and PPAP (Production Part Approval Process) throughout the product development lifecycle.

Automation initiative

For the SME sector, customised and cost-effective automation is the need of the hour, and there are challenges in identifying the right solutions considering ROI, cost-benefits, etc. Shriram Rubber have invested in an Automatic Chemical (batch) Weighing System for improved accuracy, reduced internal rejection and batch consistency. This system is a Poka-Yoke or mistake-proofing in the rubber compounding, which is necessary in the rubber product manufacturing process.

They have also installed a rubber compound strainer and high-precision preformer for producing preforms (blanks) that are uniform in weight and size, and are practically free of foreign particles/contamination. In the future, they are also looking to improve effectiveness and efficiency in the visual inspection process through automation.

Buy-in from team members is crucial, and their inputs and suggestions are valued. The leadership has several discussions on the potential benefits and how they can perform more value-added activities if the simpler and repeatable tasks are automated.

Standards & Continuous Improvement

Shriram Rubber is certified for IATF 16949 (Quality Management), ISO 14001 (Environmental Management), and ISO 45001 (Occupational Health & Safety Management). The company serves a global OEM customer base and is subject to rigorous audits. These audits are conducted by certifying bodies as well as their customers across all operational processes.

The management places strong emphasis on making the relevance of these standards clear to the team, highlighting them as avenues for improvement, safety, and environmental responsibility. Each standard is translated into practical, actionable value for employees.

Awareness and refresher training are conducted regularly on topics related to each of these systems. Cross-functional teams are actively involved in internal audits, risk assessments, and corrective action processes. Improvement initiatives, such as Kaizen, are encouraged, and team members are rewarded for their contributions to these efforts. The company’s KPIs are aligned with the standards and monitored regularly. Active engagement comes from the involvement, accountability, and seeing the value of these systems in the team’s everyday work.

Sustainability initiatives

SRPPL follow a stringent environment, health and safety policy that monitors the environmental impacts of their processes. They ensure legal compliance with environmental and safety regulations. They have an operating consent from the State Pollution Control Board to monitor the emissions. SRPPL is responsible for the procurement of materials, and these rubber compounds are compliant with REACH and RoHS (2) regulations.

The internal rejections are controlled, thus reducing the wastage/scrap generated. All the human resource policies are in place and strictly adhered to.

SRPPL is highly concerned with human safety. A structured training framework is in place. They have a mix of in-house training and external agencies for firefighting, first-aid for the emergency response team, along with regular safety drills and awareness training. KPIs related to environment, health, and safety are monitored monthly, and leadership actively promotes the sharing of ideas, kaizens, poka-yokes, and other improvements within the organisation. In terms of Corporate Social Responsibility, the organisation donates to various educational institutions.

Leadership & Compliance

Top management develops and executes the overall strategy, drives customer engagement, oversees financial operations, and guides the team toward shared objectives. While the leadership remains actively involved in product development and operations, these areas are managed on a day-to-day basis by experienced and capable professionals.

When working with customers across different geographies, compliance with international standards such as REACH and RoHS is a top priority. This is achieved through systems of material traceability, internal and external testing, and supplier validation. All raw materials used in the production are sourced from certified vendors with the necessary documentation to demonstrate compliance. The in-house QA team is trained on global environmental and safety regulations, and the company regularly updates its practices to align with changes in compliance frameworks. Additionally, they conduct third-party audits and maintain certifications.

Market reach and customer relationships

Shriram Rubber manufactures customised products, which require a thorough technical understanding of the product specifications and end application. They have an experienced cross-functional team that establishes the right manufacturing process to develop products within the committed lead time.

Along with product quality and on-time delivery, the organisation believes in transparent and win-win relations with all its customers, thereby strengthening collaboration. Prajakta regularly visits and meets her customers in person to understand their feedback, along with her team. Many of the additional business opportunities are due to existing customer references, and the organisation is actively seeking new avenues by participating and exhibiting in industry trade fairs.

————————————————————————————

Interview

Priya Barve, Joint Managing Director, Shriram Rubber Products Pvt. Ltd., Pune

Prajakta Kotasthane, Managing Director, Shriram Rubber Products Pvt. Ltd., Pune

Manufacturing has long been a male-dominated field. As women leaders in this space, what have been your key takeaways and challenges along the way?

Prajakta

I believe it ultimately comes down to capability and effort, regardless of gender. While there are challenges, some of which are gender-related, every career, organisation, and aspect of life presents its obstacles. Effectively navigating these challenges is an important part of the learning process and overall development.

Priya

In any professional environment, “putting your company first” means aligning individual efforts and decision-making with the organisation’s broader goals while staying true to our core values, regardless of gender roles.

Manufacturing environments can be physically, mentally, and culturally demanding. Over the years, consistently performing well and delivering results while ensuring customer satisfaction have helped shift perceptions and earn respect, regardless of gender. We have been fortunate not to face significant challenges related to gender bias. We see it as an opportunity to demonstrate that leadership is not limited by gender.

If you had to sum up the philosophy of Shriram Rubber in a couple of lines, what would it be?

Prajakta:

I believe our 5 Core Values – customer satisfaction, efficiency & effectiveness, continual improvement, teamwork and ethics – essentially sum up our philosophy.

Priya:

Shriram can be summed up as “A Name You Can Trust”. We are proud to say that we have acquired customers because they trust us, our team, our capabilities and our commitment towards delivering the right quality of products at the right time. Shriram is recognised as a preferred supplier/single source supplier of many of our customers. With a vision to become a leading supplier globally of critical, value-added rubber components, we aim to achieve this while remaining true to our five core values.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.