Making of the heart of machines

By Staff Report July 7, 2025 1:46 pm IST

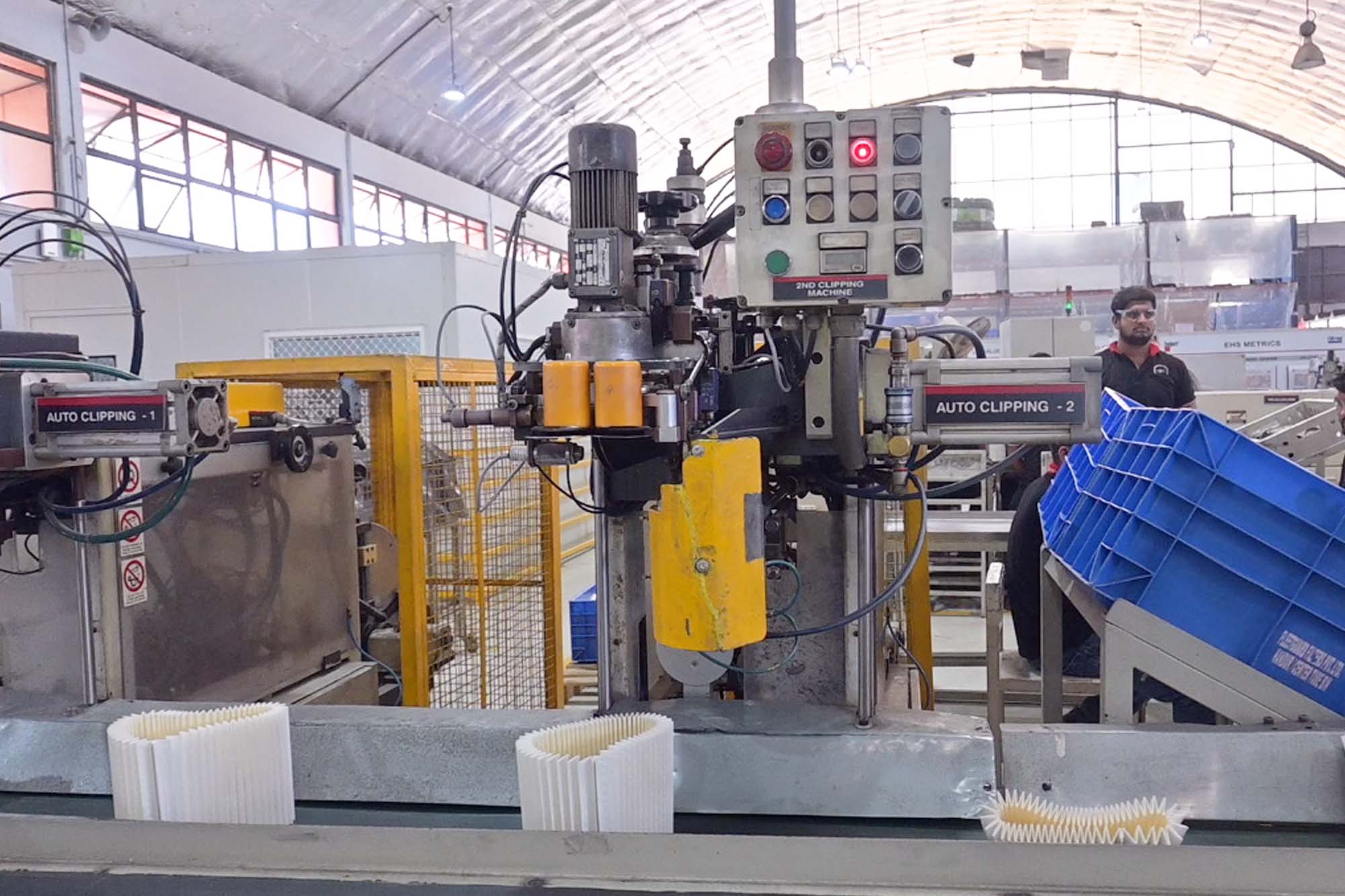

OEM Update recently toured the Pune facility of Motor Solutions business of Godrej Enterprises Group. The facility has an annual production capacity of over six million motors and offers more than 300+ customised stock-keeping units (SKUs) to cater to a wide range of industrial applications.

Located on a spacious 36-acre manufacturing campus in Shindewadi, Pune, the Motor Solutions division has been in operation since 1991. It benefits from a highly localised supply chain, with most of its vendors situated within a 100-kilometre radius. This positioning enables the business to leverage Pune’s robust manufacturing and automotive ecosystem, allowing it to serve customers nationwide and to export markets, including the US and Europe.

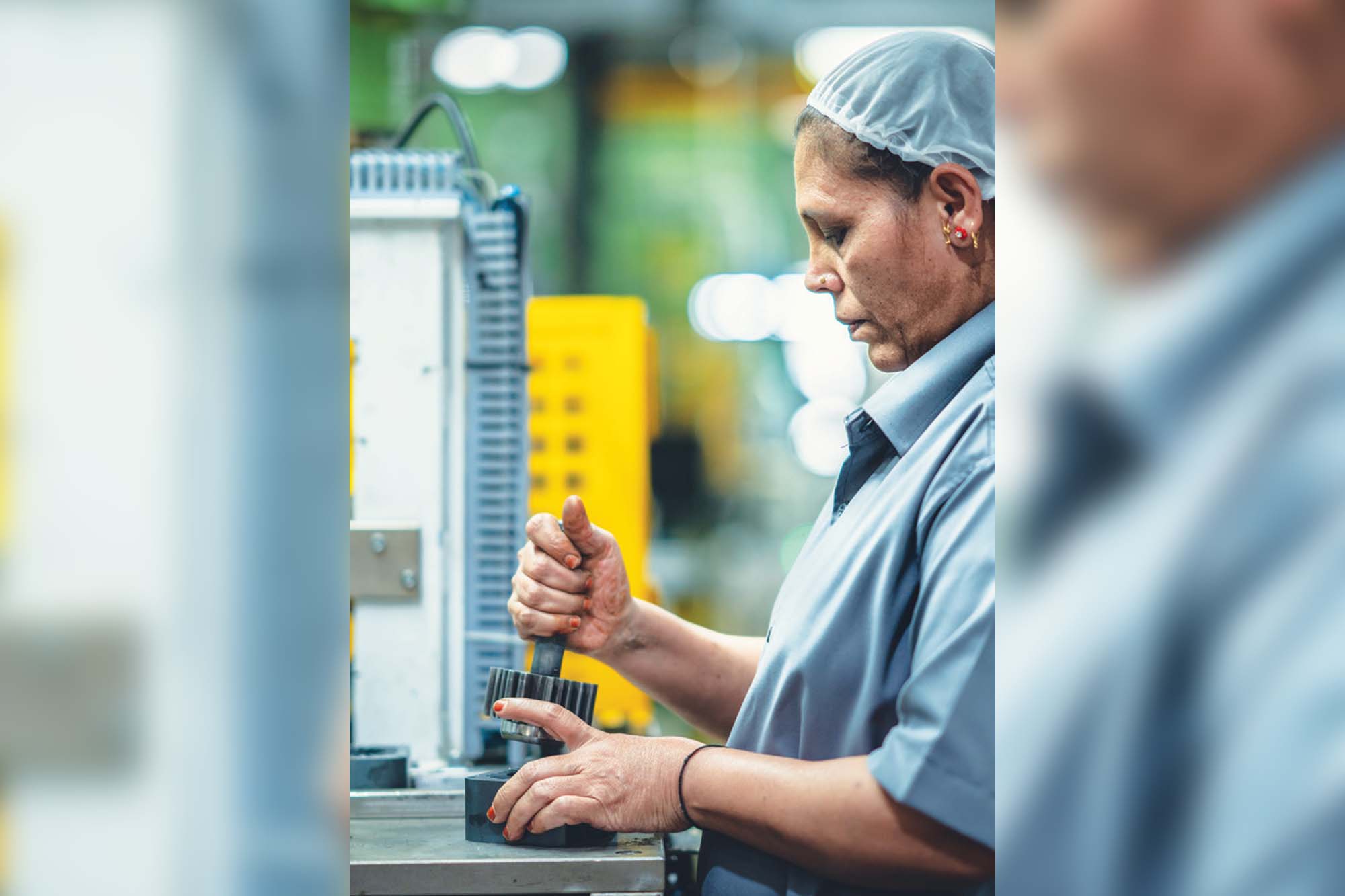

The Motor Solutions business of Godrej Enterprises Group manufactures specialised electric motors, including hermetic compressor motors, custom-built three-phase and single-phase motors, and motor components such as wound stator and rotor assemblies, as well as laminations and stampings for various applications, across all segments in India and international markets.

The Pune facility is designed to produce high-efficiency motors that comply with global standards for productivity, safety, and environmental sustainability.

Green Transition and Miniaturisation in Motors

The facility is focused on making motors more environmentally friendly. Traditionally, compressor motors used in applications such as refrigeration have involved bulkier components and conventional gases. However, the transition to eco-friendly refrigerants demands changes in motor insulation and installation systems. Godrej is actively working on adopting new technologies that support these requirements.

Efforts are also underway to drastically reduce the size of motors without compromising output. The team is developing motors for high-speed blowers that can operate at higher speeds, up to 40000 RPM. While this enhances efficiency and compactness, it also introduces challenges, such as the need for advanced lubrication and complex designs. The objective is to deliver the same performance using smaller motors, thus optimising material uses and energy consumption.

Innovations in motor design and manufacturing

The transition from traditional laminated motor bodies powdered metallurgy components aimed to make motors compact and efficient. Godrej is also working for eliminating the need for rare-earth magnets in certain designs. These motors utilise two types of windings: one to generate magnetic fields and the other for rotation, thereby forming synchronous motors. The large-size variants are already in production, but scaling down for smaller motors remains a challenge.

Godrej’s motors are being developed for niche applications, including marine use and defence. One motor, designed for aeronautic applications, involves a complex winding process using flat wires, which is an intricate task, especially given the tight dimensional tolerances.

Vertical integration and digitisation

Most of the drive cards, and software are designed and manufactured in-house. The production line utilises wave soldering and automated testing, producing between 30,000 and 40,000 electronic cards per month. Motors are assembled in compact lines with efficient layouts. Each unit undergoes rigorous end-of-line testing under load conditions to validate performance metrics, including speed, efficiency, and power factor. Certified samples from each batch are stored for five years, ensuring traceability in the event of quality concerns.

Advanced Tooling and Lamination Processes

Godrej has developed capabilities to produce lamination tools domestically. These laminations, particularly for automotive applications, are made thinner and more complex for better performance. Segmental punching techniques are employed to minimise the waste of exotic materials in stator manufacturing, while rotor components are fabricated using more common materials. Achieving and maintaining tight air gaps with thin punches requires extreme precision and constant tooling investment.

Each lamination profile demands a unique toolset. The factory maintains hundreds of tools and frequently replaces them as they wear out. Punching is done at high speeds (200–250 SPM), demanding consistent tool alignment and maintenance. Earlier, these tools were imported; now, Godrej manufactures and assembles most of them in-house, sourcing only specific components from abroad.

Smart Manufacturing and Automation

The plant integrates digital systems to capture real-time machine data, eliminating the need for manual logs. This software was developed in partnership with Godrej Infotech at an investment of over 3 crs., which enables root cause analysis and predictive maintenance.

Automation has been incorporated across many processes. In the case of motors used for electric vehicle (EV) battery cooling, the winding lines are fully automated and operated with minimal human intervention. Each component is completed in 20 seconds on these lines.

Heat Treatment, Annealing, and Material Science

Heat treatment processes are vital for improving magnetic properties. The laminations are treated at 750°C in controlled atmospheres, using a mixture of nitrogen and hydrogen. The furnaces operate at 650 kW and are designed to minimise heat leakage. Post-treatment inspections ensure quality standards are met before components proceed to the winding or assembly stages.

Infrastructure and Sustainability

The plant’s infrastructure is thoughtfully designed for efficiency and climate resilience. It features a full concrete slab roof to reduce heat and noise, a 22.5-metre-wide span to facilitate easy layout changes and natural ventilation, and to maintain internal temperatures. These thoughtful architectural decisions enable long-term adaptability and comfort for the workforce.

Approximately 90% of the company’s packaging is made from recycled and environmentally friendly materials. Corporate Social Responsibility (CSR) initiatives are focused on environmental sustainability. The facility’s roof is equipped with solar panels, which currently meet 20–25% of its energy needs. Plans are underway to further expand this capacity. The company holds both GreenCo and IGBC certifications and actively runs community programs in the region to promote innovation and civic engagement. Additionally, it collaborates with the Naoroji Godrej Centre for Plant Research (NGCPR) to support environmental education and related initiatives.

Customer Experience Centre

This Shindewadi Plant has a Customer Experience Centre which replicates real-world application conditions. When customers visit, they can observe how the motors perform in these scenarios. Simulation plays a crucial role in this process. The company has world-class testing labs equipped with 4D controllers specifically for energy-efficient motors. Its R&D facility is capable of testing motors under a variety of conditions, ranging from extreme climates to infrastructure challenges.

Future

Specialised motors will continue to be a key focus for the company, particularly for exports, where strong demand has already been established. These motors require new technologies, including BLDC (Brushless Direct Current), switched reluctance, and synchronous reluctance motors. The Motor Solutions business of Godrej Enterprises Group is targeting a revenue of INR 1000 crore by FY28, with 20% of total revenue coming from exports. The company is targeting ₹750 crore in FY26, driven by expanding demand across electric vehicles (EVs), HVAC applications, pump applications, and actuator segments in domestic and international markets.

To capitalise on these opportunities, investments are being made in high-speed presses and fully automatic lines for open motor components, laying the groundwork for future growth.

An earlier experiment involved integrating a chip into one of the motors to monitor key performance specifications, such as speed and density. As electronics become an integral part of motors, software is expected to play an increasingly significant role in their operation. The company is also advancing into smart manufacturing by equipping the shop floor with sensors and electronics to enable performance monitoring and swift issue resolution. This area remains a clear focus moving forward.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.