The effect of advanced metal forming and laser cutting

By OEM Update Editorial November 1, 2023 12:56 pm IST

Anil Mighlani, Managing Director of Angel India CAD CAM, explores innovation in the metal forming industry guided by cutting-edge technology, robotics, and sustainable practices. He asserts additive manufacturing represents the future of metal forming.

What latest advancements in laser cutting are impacting the metal fabrication industry?

The evolving market demands are presenting significant challenges to the industry. Embracing our role as industry leaders, we have harnessed new technologies to address these challenges. Our company has risen by introducing advanced bevel-cutting solutions for high-thickness materials. This transformation has simplified a cumbersome task into a streamlined process, resulting in substantial time and material savings.

How have the metal-forming processes evolved in your facility over the years?

India is striving to reach a five trillion-dollar economy, and in recent years, metal forming has emerged as a significant contributor. The scope of metal forming has expanded substantially, driving growth in various factories by adding specialized machinery. These dedicated machines, such as CNC technology, have simplified complex tasks, making processes like creating cones much more efficient and accessible than before.

Please talk about new sheet metal working and forming equipment and robotic and automation solutions.

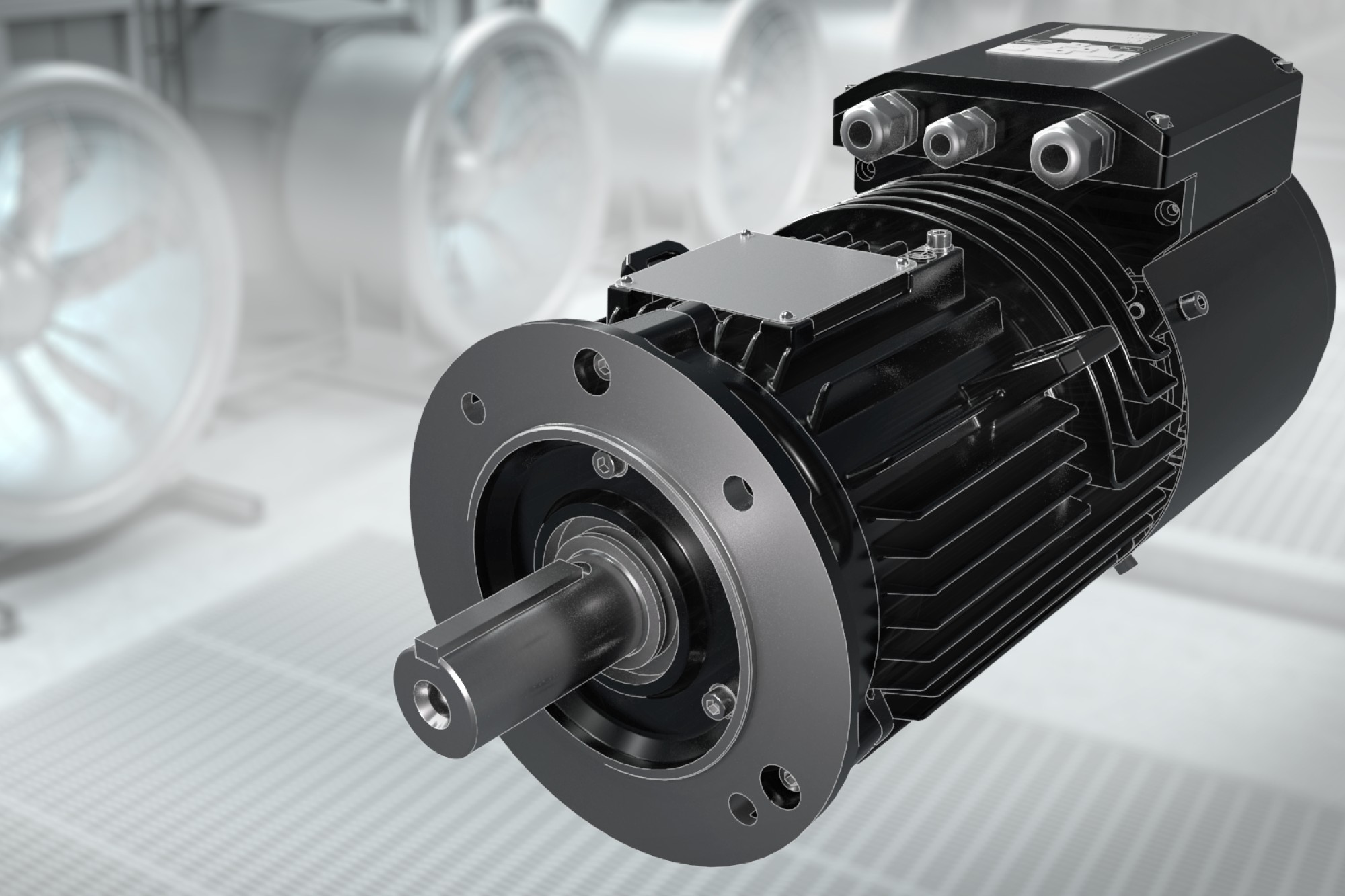

The market’s demand for increased production is growing steadily. To address this, we are enhancing our production capabilities, and robots have emerged as valuable assets in meeting these challenges. Additionally, there is a range of customized machinery available to support daily production needs. These new machines and robots not only enhance the quality and efficiency of our work but also contribute to the refinement of designs and shapes, meeting the industry’s evolving requirements.

The automotive sector is an engine for a country’s economic growth. In today’s highly competitive landscape, companies vie for a larger market share. To retain their standing, they must continually introduce new, appealing models. Metal forming is pivotal in meeting the automotive sector’s escalating demands, increasing the need for customized machinery. As a result, manufacturers of metal forming machines encounter fresh challenges daily, and we are consistently delivering new machines to meet these requirements.

Can you discuss sustainable practices to address the environmental implications of metal-forming and laser-cutting processes?

Excessive industrialization has posed a significant sustainability challenge across various sectors. Laser cutting is a valuable solution to mitigate pollution and offers excellent sheet coverage. Additionally, transforming numerous conventional machines into CNC machines has enhanced productivity, quality, and efficiency.

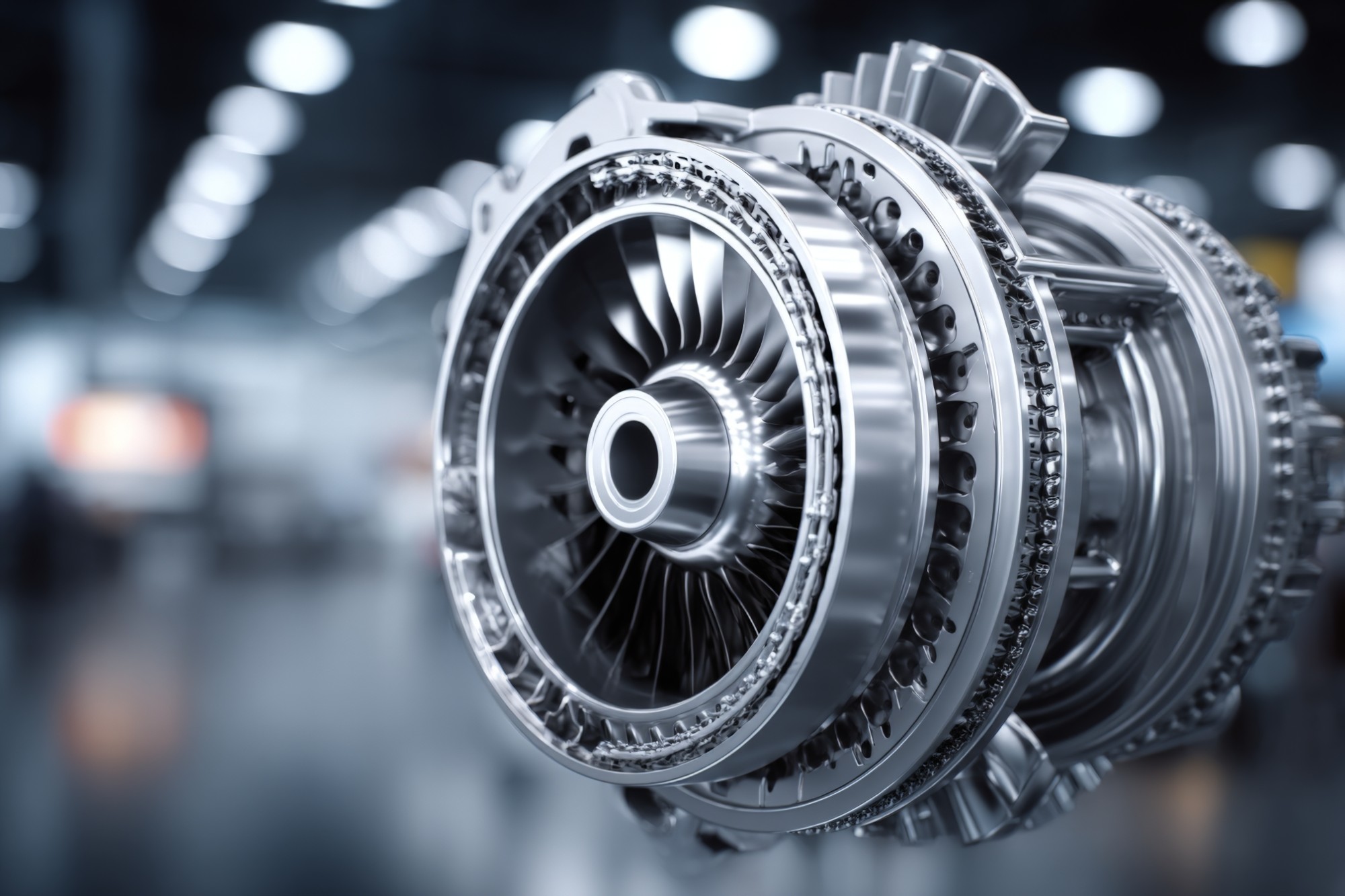

How do metal forming and laser cutting technologies contribute to the manufacturing of complex metal components?

Laser-based additive manufacturing is serving as a crucial component in the manufacturing process. It has simplified and expedited the production of intricate designs, offering a high level of precision, which was previously challenging to achieve. Due to lasers, these tasks are accomplished with greater ease and speed, approaching near-perfection. Shortly, additive manufacturing is expected to gain momentum, replacing traditional machinery. Additive manufacturing represents the future of metal forming.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.