Manufacturing sector is undergoing an industrial revolution

By OEM Update Editorial June 9, 2022 6:37 pm IST

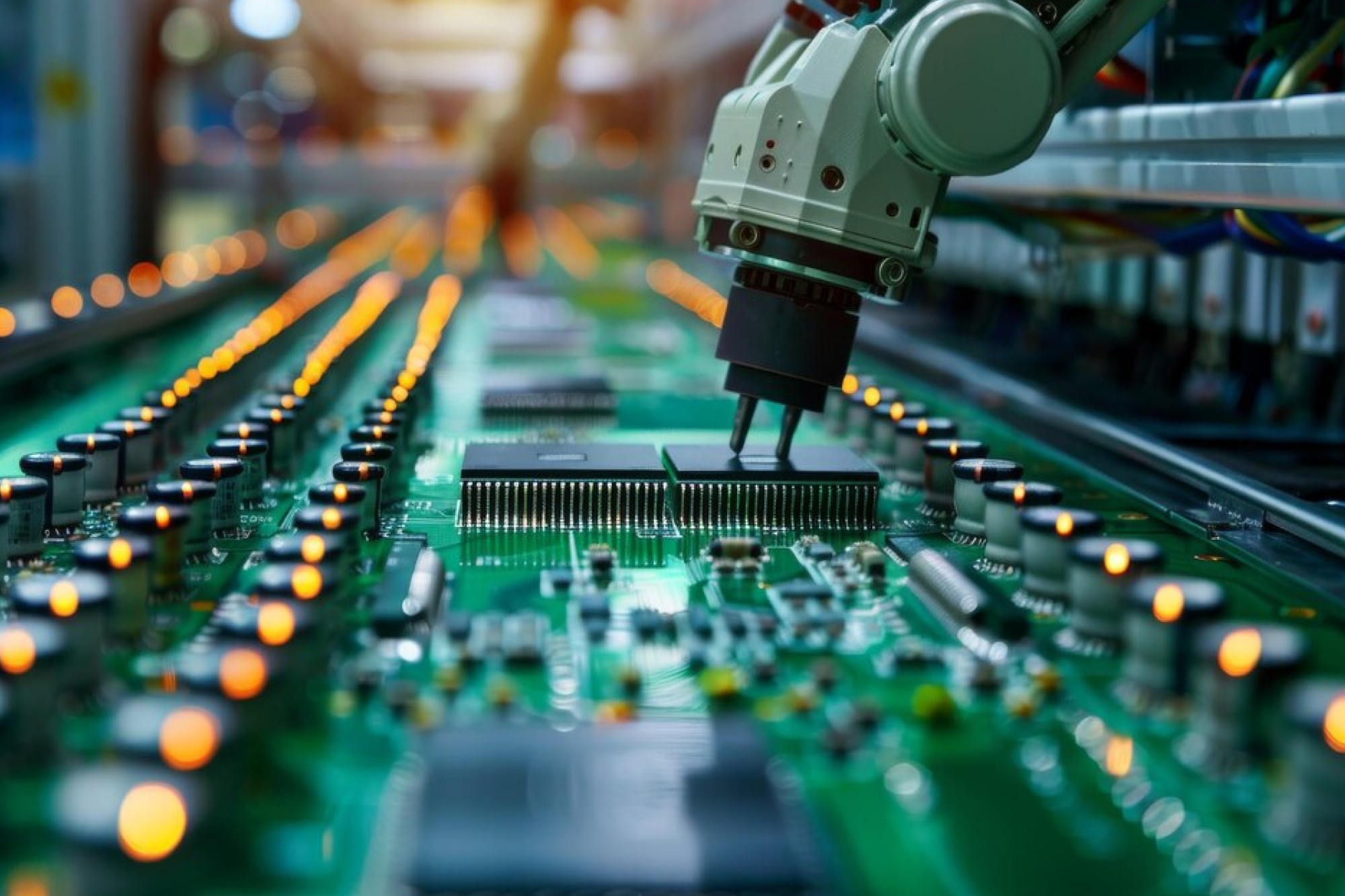

The manufacturing industry is being transformed by Industry 4.0. With manufacturing facilities incorporating higher degrees of automation, the demand for new technology is continuously increasing.

While interacting with OEM Update, Sivakumar M, Business head, Industrial Chain Division. Tube investment of India Ltd., remarked, the demand for new technology is continuously increasing with incorporating higher degrees of automation.

Latest trends impacting the automation in manufacturing industry

Automation firms are rehiring more workers every day as a result of the latest technology in the manufacturing industry. Our lives, on the other hand, will be altered because of the way we manufacture and supply the goods and products that fuel our economy. Furthermore, the industrial manufacturing industry is undergoing an industrial revolution, which is known as Industry 4.0. It includes robotics, smart manufacturing, artificial intelligence, and the Internet of Things as examples of industrial innovations. The manufacturing industry is being transformed by Industry 4.0. With manufacturing facilities incorporating higher degrees of automation, the demand for new technology is continuously increasing.

TIDC products and solutions

Today, TIDC India is well-acquainted with a larger manufacturing, engineering and product development facility to provide a wide range of industrial chains and other power transmission products across industries. We supply with conveyor chains, leaf chains, special coated chains, standard roller chains and make-to-order chains, Our chains basically go into: forklifts, stackers, hoists, container handling, straddle carriers, multilevel car parking, material storage equipment and many such applications in material handling industry; which are carefully designed to provide durability, precision and longevity. As you know, 60 years of TIDC India as a company, is built over the ‘Trust in Quality’ of our chains and value addition we provide in our service.

AI, IoT ramp up chain production

The Production Linked Incentive (PLI) plan for mobile phones and components was launched with the goal of tapping the massive, expected demand for wearables, hearables, IoT, and VR gadgets. In chain industries, the devices such as using virtual reality are quite useful and we can train our employees without using machine. It is worth mentioning that the IoT devices can help in predictive maintenance, logistic management asset management, quality control etc.

Growth for auto components and transmission system in growing automobile industry

In FY23, the industry might increase by a factor of two. In contrast to earlier times, the influence of the Omicron variety is now restricted, and there is no difficulty with Covid’s new variant. In FY22, the domestic auto components sector is predicted to rise by 15-17 percent, and by 10-12 percent in FY23. However, auto component industry is facing challenges such as shortage of semiconductor chips, high costs or unavailability of raw materials and logistical issues related to exports.

Concept of cellular manufacturing in the Indian chain industry

Cellular manufacturing is the based upon the group technology. In chain industry TIDC is using cellular manufacturing. The advantage of industrial chain manufacturing include reducing cycle time and making production smoother. We use different cell for different required product.

International collaboration aids industrial advancement

The country’s economic growth is accelerated through international collaboration. Also, the technological gaps are filled through international collaboration. This obviously aids in the advancement of industrialization. Other resources, such as economic, human, and physical resources, are also mobilized as a result of international collaboration

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.