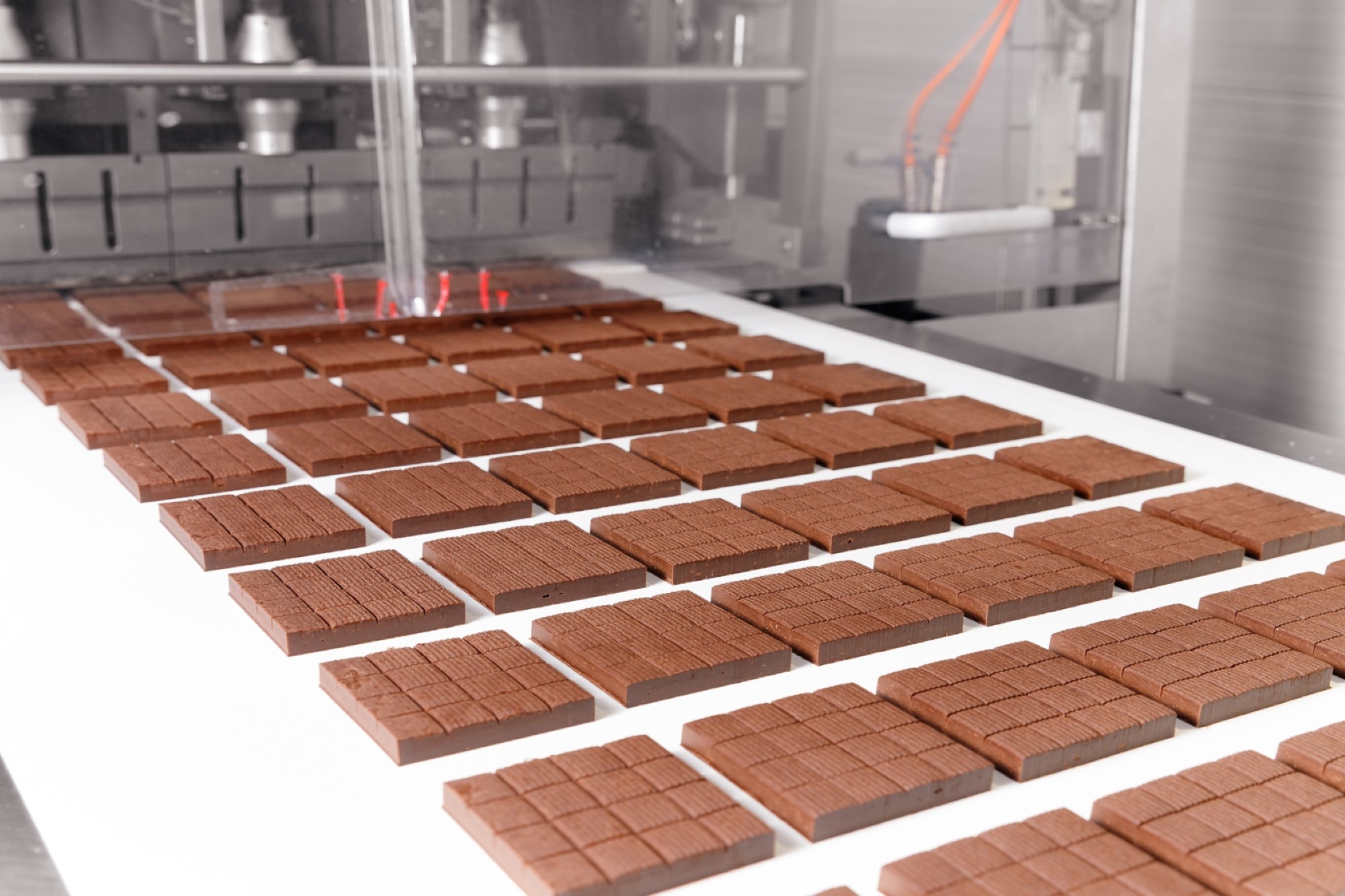

AXTEL modernise chocolate moulding line with Rockwell Automation Tech

By Staff Report June 6, 2025 5:09 pm IST

Axtel Industries offers customised solutions for the food processing industry, which require a higher level of accuracy, efficiency, and safety in their production. Discover how they achieved accuracy by integrating Rockwell Automation’s advanced solutions.

Axtel Industries has more than 30 years of experience in offering customised solutions for the food processing industry. The company’s design, engineering, and manufacturing capabilities are focused on delivering solutions that maximise profitability, ensure sustainability, and improve reliability. Axtel is a specialist in engineering process systems for the food industry. The company is recognised for its expertise in Turnkey Systems, Product Development and Customer Service. Axtel’s advanced manufacturing facility, located on the Vadodara–Halol highway in Gujarat, India, is well-equipped to build robust and aesthetically designed machines.

Challenge – Need for a higher level of accuracy, efficiency and safety in production

The field of process automation is constantly evolving, and as an original equipment manufacturer (OEM), Axtel needed to stay current with the latest technologies. To enhance productivity in a more efficient, safer, and sustainable manner, the processes and technologies in their chocolate moulding lines had to be continually updated.

The traditional process automation technology used by Axtel had limited capabilities, as different stock-keeping units (SKUs) were required for a single chocolate moulding line, including solid bars, shells with inclusions, one-shot moulding, and ribbons. The complex chocolate moulding processes, which involve fillings and book moulding for multiple SKUs on a single moulding line, require high levels of accuracy, precision, and efficiency.

In spice processing, Axtel required enhanced reporting capability as the evolving market dynamics demanded better compliance, operational efficiency, quality control, and safety.

Solution – Develop fully automated chocolate moulding line and spice processors

Axtel turned to Rockwell Automation to automate their chocolate moulding lines. This collaboration aimed to meet market demand and product innovation, boost productivity, accuracy, and efficiency, and deliver greater safety and sustainable growth for the company.

Starting in 2009, Axtel utilised Rockwell Automation’s Kinetix 6500 multi-axis servo drive to develop a fully automated chocolate moulding line entirely in-house. This helped Axtel with increasing the precision and accuracy of the processing line.

For operational excellence, in 2024, Axtel leveraged Rockwell Automation’s Integrated Architecture® consisting GuardLink® 2.0 and Kinetix® 5700 servo drives system to enhance safety and efficiency of its molding line.

In 2019, Axtel developed a fully automated ingredient management system by leveraging the ControlLogix processor and PlantPAx system to enhance efficiency and precision in spice blending solutions.

Result – Becoming a global leader in chocolate moulding

The innovative solution, built using Kinetix 5700 servo drives and Category 3 safety solutions from Rockwell Automation, has made Axtel’s chocolate moulding lines a leading choice in the global market.

In spice processing, managing multiple ingredients, including small and micro, while ensuring data integrity has significantly supported the manufacturing process for spice processors. This automation has improved precision and efficiency, leading to enhanced quality and consistency in the final product.

Overall, in its manufacturing solutions, Axtel has reached the PLd Safety Performance Level. This accomplishment has made Axtel-manufactured machines and process plants safer and more sustainable.

The innovation in automation has further led to improvements in their troubleshooting and maintenance processes, enhancing the aesthetics of the production line using a common controller and simplifying the wiring. Additionally, it enables remote troubleshooting through EIP connectivity.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.