IIoT: The next big jump

June 11, 2018 4:39 pm

Mahathi Parashuram,

Regional Head – Public Affairs, Communications & Relations, Grundfos Asia Pacific Region

With the increased adoption of IIoT, manufacturing will become a decentralised and an autonomous process.

IIoT has revolutionised manufacturing

Internet of Things (IIoT) or digitalisation is transforming the way manufacturers can capture, analyse and utilise data to improve business performance. The digital transformation of all industries has been gaining momentum in the region. This includes Big Data and connectivity, analytics, Artificial Intelligence, advanced interactions between humans and machines, and new production methods.

Mahathi Parashuram, Regional Head – Public Affairs, Communications & Relations, Grundfos Asia Pacific Region, says, “IIoT sure has revolutionised the way manufacturing industries operate. It has enabled access to a large amount of data, at far greater speeds, and far more efficiently than before. Predictive and proactive maintenance, real time monitoring, asset and resource management as well as remote diagnosis are just a few of the advantages that the manufacturing sector benefits by adopting IIoT.”

Based on a report by Deutsche bank the adoption of IIoT will help the manufacturers to increase their productivity by 30 per cent. Overall the elements such as connectivity, efficiency, scalability, time savings and cost savings for industrial organisations has been improved. It also allows the industries to get the most value from their system without being constrained by either technical or economic limitation.

Imagine a process that can monitor and govern itself, where smart products can avoid damages by taking corrective measures and replenish individual parts automatically. She adds, “With the increased adoption of IIoT, manufacturing will become a decentralised and an autonomous process.”

Slowly the barriers between individual facilities is disappearing as multiple factories, regions become part of a larger single network. This will in turn improve the supply chains, transforming them into flexible and value-added networks through which manufacturers and suppliers can interact on a co-operative basis.

While there are many businesses that are sceptical to join in this trend, the ones who have embraced IIoT have seen significant improvements in their business processes. Parashuram believes IIoT is clearly the next big jump as it is deemed by many as the 4th Industrial revolution or Industry 4.0. The sceptical businesses will have to plan towards the future or play catch up as many believe that this trend will continue as more and more business adopts IIoT.

While the manufacturing industry may be the largest user of IIoT, transport and logistics, gas and energy industries, pharmaceutical firms, and food and beverage companies are also quickly becoming the major adopters of IIoT for all their processes. With the market becoming extremely competitive, businesses are looking at how they can achieve greater efficiencies at half of the original cost. With IIoT they can achieve exactly that. For example the usage of IIoT has revolutionised the way transport and logistics industry function these days, especially while freight tracking. Now it has become possible for the cargo owners to track their shipment right from the moment it leaves the inventory till the time it reaches the pre-decided destination.

Even pharma companies are investing heavily into IIoT as automation and efficiency is highly essential for them to stay ahead of their competitors. Adoption of IIoT provides them with the accessibility to look at each of their processes at an individual level without compromising or affecting the other processes. In case of any error, it wouldn’t require them to halt their entire operation. They can, with ease look at the issue and solve it remotely.

Parashuram observes, “Another sector where we are seeing increasing interest is from food and beverage industry. With the tremendous importance being given to traceability, many relatively small companies have also started implementing automation for their operations but at a comparatively smaller scale. They are interested in automated reporting and stock keeping but are still sceptical in making the big change.”

Grundfos preparedness in the area of IIoT

Grundfos’ digital journey started in the 1980s when they had developed the frequency controller to be controlled by a microprocessor. Parashuram informs, “We became the first ever pump company to introduce electronics in pumps. Even before the boom of IIoT one of our early technologies had made it possible for our pumps to send messages directly to the pump owners regarding all the information about the status of the pumps etc. Over the years we have developed numerous intelligent pumping solutions that are being used world over. As today’s generation has become extremely technology savvy, we are also taking appropriate steps to make our digital interactions simpler, more integrated, and effective.”

Intelligent connectivity with Grundfos iSOLUTIONS

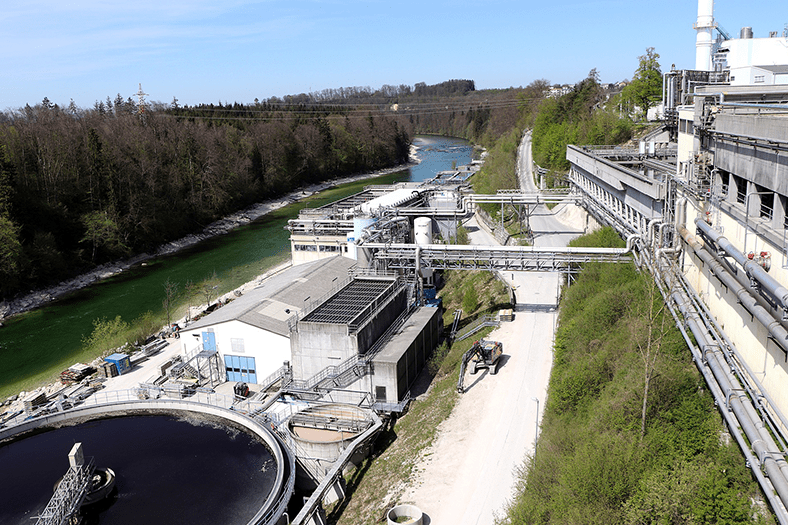

Another digital pump solution Grundfos have is the Grundfos iSOLUTIONS. With its state-of-the-art pump intelligence it ensures that all the pumps, drives, control and protection units, measurement and communication units all work together as one complete, energy efficient and connectivity-based system. Grundfos iSOLUTIONS products offer intelligent solutions such as working autonomously according to actual demands, dynamically changing control modes, providing intelligent warnings and related information as well as seamless adaptation to fluctuating conditions. The Grundfos iSOLUTIONS products also boast of full system connection to send and receive all data, distributed sensors to reduce leakage and save energy, controller interlocks to prevent flooding and instant information on performance operation. It provides a system utilising increased monitoring, control and integration to achieve greater energy efficiency, reduced system complexity, low life-cycle costs. Whether the requirement is for a solution for applications such as cooling or heating, pressure boosting, boiler feed or wastewater treatment Grundfos iSOLUTIONS provides a customised solution that will fit the bill.

SMART Digital XL DDA and DDE dosing pumps

Under its iSolutions range, Grundfos latest SMART Digital XL DDA and DDE dosing pumps is able to dose in accurate measurements, which cuts out unnecessary chemical consumption, while consistently reaching processing targets. Such Industry 4.0 technology leads to less waste and more efficiency – ultimately less cost for the food manufacturer and more safety for the consumer.

Parashuram informs, “While our key focus is on developing sustainable digital products ready for the future smart cities, we always have put a lot of emphasis on providing a world class service to our customers. Recently to reduce the communication gap between the end users and our engineers we launched a mobile application called SmartServ. Just like any other app you can easily locate a service provider nearest to you, fill in the required details of the complaint or request, attach a picture of the pump/system and raise the service request. You would receive an acknowledgement of the request within four hours. A user – friendly mobile app, it is easily available on iOS, Android and Windows.”

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.