Universal Robots hosts C-Suite Roundtable on i 5.0 in Mumbai

By Staff Report September 9, 2025 5:51 pm IST

Universal Robots – A Teradyne Robotics Company hosted an exclusive C-suite roundtable in Mumbai, uniting industry leaders to explore Industry 5.0’s human-robot collaboration and discuss the multitude of automotive and pharmaceutical manufacturing sectors.

An exclusive C-suite Roundtable, hosted by Universal Robots on August 5, 2025, in Juhu, Mumbai, was in collaboration with OEM Update magazine. This closed-door event brought together key stakeholders and senior decision-makers from the automotive and pharmaceutical manufacturing sectors to explore “Transitioning to Industry 5.0: Collaborative Robotics for a Resilient Future.”

The conversation was moderated by Shirish Kulkarni, the Managing Director of Strota ConsulTech and co-moderated by Virupakshappa Hovale, Regional Director, South Asia, Teradyne Robotics. It focused on the evolving role of robotics in manufacturing and the future of healthcare and sustainability. The panel consisted of Jitendra Mishra, Senior VP at Akum Drugs & Pharma; Jasmine Gorimar, Head of Digital Transformation at Nissan Motors; Eva Verstraelane, Consulate of Belgium, Trade & Investment Dept; Poi Toong, VP of Sales – APAC, Teradyne Robotics, Shatyabrata Das, Senior General Manager at IAC – International Automotive Components; Falgun Jani, Business Head – India at Freudenberg Medical; Vaibhav Pathak, AVP – Operations at Fleetguard Filters; E. Rajiv, Executive Director of IACE – International Automotive Center of Excellence – A JV between Government of Gujarat & Maruti Suzuki India; Sachin Deshpande, Managing Director of InnoBytes; Rajib Jena, CEO of Zordiso; Vishal Shilamkar, AGM – Production at Serum Institute of India; Dr.Anubha Khale, Consulting Partner at ARQ Solutions LLP and Dr Jaywant Pawar, Senior Business Development Manager at Schott Pharma Schweiz.

The core theme of the round table, as led by the moderator, Shirish Kulkarni, was a nuanced exploration of the “coexistence” of human ingenuity with advanced technology, moving beyond the simple narrative of automation to a deeper understanding of collaboration, sustainability, and humancentric innovation.

Key discussion themes explored how cobots boost flexible and decentralised production systems by integrating them with AI, IoT, and MES. The other topics that were covered were leadership and workforce strategy of balancing human potential with robotics, which can build resilient teams.

Challenges and disparities

The panel identified that the implementation of Industry 4.0 technologies is proceeding at a non-uniform pace across the industrial sector. There is a notable disparity between the large-scale adoption efforts of major corporations and the more gradual progress observed amongst SMEs. This segmentation brings challenges in the development of a cohesive and integrated industrial ecosystem.

A primary obstacle to widespread adoption is the capital investment required for digital transformation. The panellists noted that such projects typically entail a lengthy return on investment (ROI) period, which can deter organisations from committing the necessary resources. The group agreed that a more practical approach is needed. They recommended that businesses start with high-impact automation solutions before addressing more complex and larger changes. This way, companies can make steady improvements and show clear results to support future investments.

What is the role of Data and AI?

Data is the new oil, and it is fueling today’s industrial processes. Advanced technologies like robotics and AI work best when they have access to high-quality, standardised data, as was put forth by panellists. A key point of agreement among the panellists was that a lack of “clean,” consistent data across an organisation’s value chain can be a barrier to achieving true digital transformation.

AI and machine learning are now used in many areas. For example, they can speed up research and development and make production cycles more efficient. The idea of a digital thread, which connects each stage of a product’s lifecycle with data, is seen as key to achieving sustainability and circular economy goals.

Artificial intelligence (AI) and machine learning are bringing innovation across various fields. For instance, they can assist in research and development processes and also improve the production cycles. A concept known as the digital thread, which links each stage of a product’s lifecycle through data, is considered essential for achieving objectives related to sustainability and the circular economy.

Industry 5.0

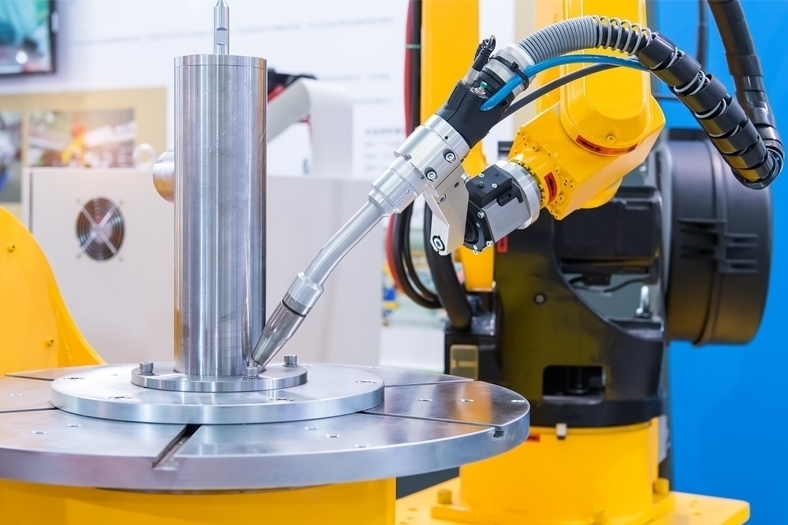

The panel addressed the emerging concept of Industry 5.0, which shifts the focus from pure automation to a human-machine collaboration arena. The objective of advanced technology is not to replace human workers but to boost their capabilities. The use of collaborative robots, or “cobots,” is a prime example of this model, whereby technology handles repetitive or hazardous tasks and human employees can focus on higher-value, more creative, and problem-solving activities. This collaborative approach enhances both productivity and worker well-being.

The discussion also confronted the longstanding societal apprehension regarding job displacement. Citing a perspective rooted in historical context, it was noted that past industrial revolutions have consistently led to the creation of new, more sophisticated roles, even as older ones become obsolete. The imperative for organisations is to implement robust change management and upskilling programs to equip their workforce with the competencies required to adapt to new technologies. The ultimate value of this evolution, it was posited, lies in leveraging technology to enable novel applications, such as personalised medicine or highly customised manufacturing, thereby creating a more resilient, sustainable, and inclusive industrial future.

Summary and strategic outlook

The panel discussion offered a thorough analysis of the industrial evolution, highlighting that the future lies in a strategic journey centred around human-robot collaboration. Key challenges identified include securing long-term investments, the inconsistent adoption of technology across different company tiers, and fundamental issues related to data integrity. A successful approach to Industry 5.0 requires a comprehensive strategy that balances technological ambitions with practical implementation.

The discussion stressed that the true value of this new industrial era resides in intellectual applications, such as personalised medicine and highly customised manufacturing, where collaborative robots (cobots) and automation enhance human capabilities rather than replace them. Organisations must invest in essential digital infrastructure, prioritise data standardisation, and foster a culture of continuous learning and upskilling for their workforce. The future of industry will be characterised by a synergistic relationship between human ingenuity and collaborative robotics, with technology acting as an enabler for higher-value, creative, and problem-solving activities. Ultimately, this will lead to a more resilient, sustainable, and inclusive industrial future.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.