Safety solutions customised for each need

By Staff Report May 2, 2025 11:35 am IST

Safety is paramount, in the air and on the ground, for food production from pharmaceuticals. SCHMERSAL has a global approach to providing safety solutions to the industries as and when needed. Prakash Karunamurthy from SCHMERSAL INDIA PVT LTD shares that they follow regional standards of the place they are making the solution for to make themselves adaptable.

How do Schmersal’s safety solutions assist logistics and supply chain management? What technology is deployed especially for airports?

Schmersal offers a broad portfolio of industry-specific safety components and systems for warehousing and material flow, as well as a diverse range of products for industrial trucks.

In intralogistics, there are high demands on the productivity and fail-safety of the systems. Schmersal’s safety solutions are ideally suited to meet these demands: The intelligent safety components with extended diagnostic functions can provide a wide range of operating data. As data suppliers, we thus support the monitoring of processes in line with Industry 4.0. In addition, our products can provide maintenance information so that components can be replaced to minimise downtimes and failures—a plus point for predictive maintenance.

Schmersal safety installation systems enable simple, fast, and error-free installation of safety switches and reduce wiring effort—a considerable (cost) advantage in complex intralogistics systems.

Safety is paramount in air transportation, both in the air and on the ground. For example, many baggage handling systems operate in airport terminals, an important element of sophisticated logistics that transports millions of suitcases quickly and reliably to and from the right aircraft.

We offer a broad portfolio for airports, consisting of automation components and safety solutions for airport logistics. These include our robust command and signalling devices, position monitoring, and non-contact protective devices that ensure the safety of passengers and operating personnel on conveyor belts.

In conjunction with an intelligent wiring concept for forwarding comprehensive diagnostic information, our safety components enable rapid troubleshooting during malfunctions, thus ensuring smooth baggage transport.

How does Schmersal ensure its safety solutions meet the hygiene, durability, and compliance standards of the F&B and pharma industries? What sets them apart in delivering safe and easy-to-clean solutions?

We have a broad product portfolio of safety switchgear and control systems that meet the requirements of “hygienic design” and are certified according to industry specifications (e.g. Ecolab, EHEDG, FDA) for the food industry. Products designed for this area meet humidity, moisture, detergent and temperature resistance requirements.

Many safety switches in the range specially developed for the food industry are made of stainless steel. This material is particularly well suited to the industry due to its hygienic properties and robustness. We supply safety sensors, solenoid interlocks, position switches and control devices certified by ATEX and IECEx directives. Since organic dusts are flammable under certain conditions, the regulations for dust explosion protection must be observed when filling and storing powdered foodstuffs or their preliminary products (e.g., flour, baking mixes, coffee and cocoa powder).

How have industrial safety standards evolved, and how has Schmersal adapted?

Industrial safety standards have evolved due to technological advancements, increased automation, regulatory updates, and a growing emphasis on worker safety.

We have advanced safety products such as modular and programmable safety controllers (like Protect PSC1) that align with modern standards such as ISO 13849 and IEC 62061.

Our sensors and switches support contactless operation, IP-rated enclosures, and wireless integration, which is ideal for automated and hygienic environments.

We offer System Solutions for Industry 4.0. We offer safety field boxes (e.g., with PROFINET/PROFIsafe, EtherNet/IP) that integrate easily with modern industrial networks. Our systems support predictive maintenance and remote diagnostics, enhancing operational efficiency.

We provide consulting and training services to help companies comply with updated standards and conduct risk assessments and CE marking.

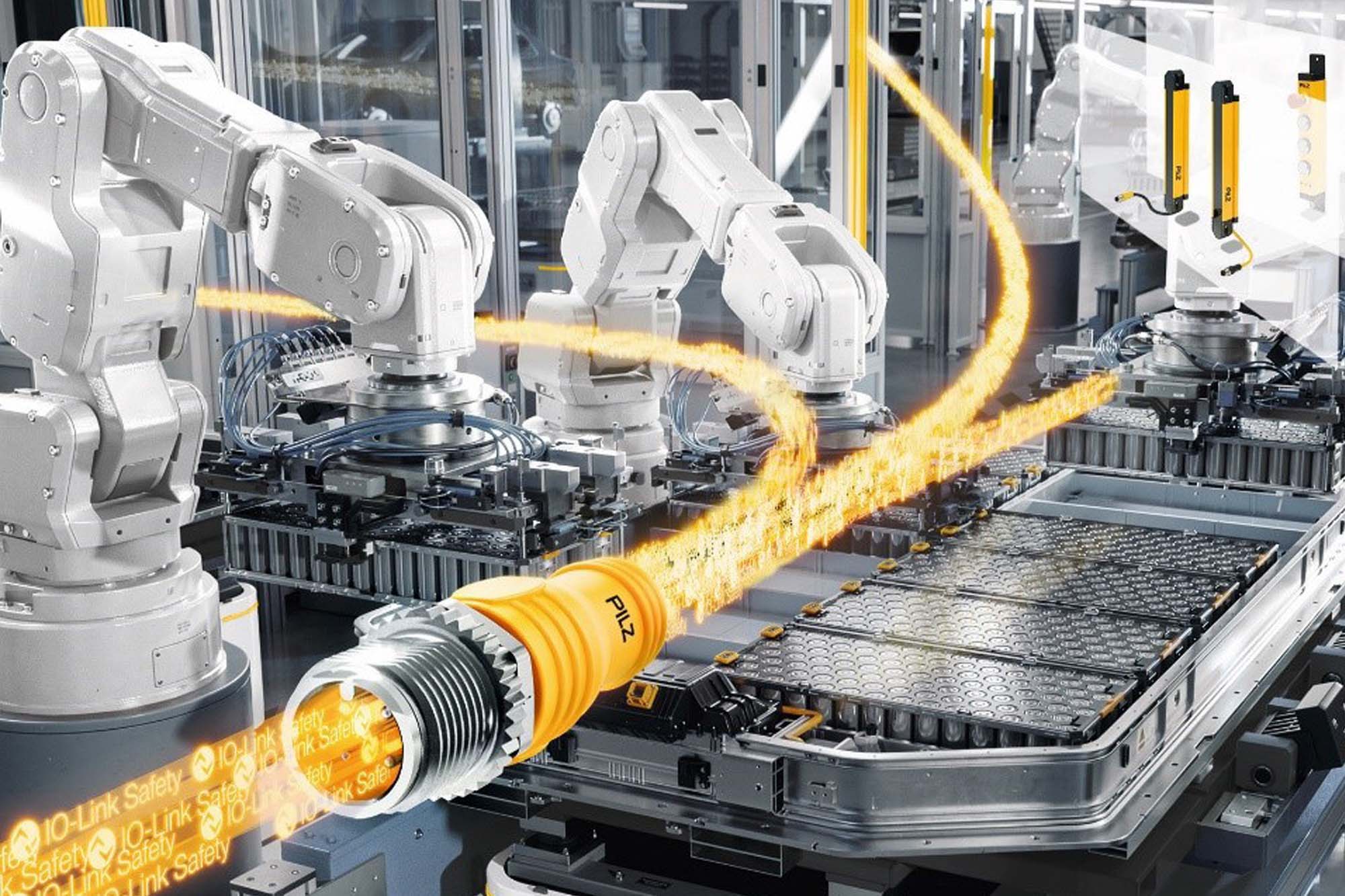

We design products that support collaborative robotics, ensuring safety without compromising productivity. For example, safety light curtains and interlocks facilitate safe and ergonomic human-machine interaction.

Our products are made with global compliance with ISO, IEC, ANSI, OSHA, and regional standards, supporting multinational clients with globally approved solutions.

What role does Schmersal play in ensuring compliance with global safety regulations (e.g., ISO, IEC, OSHA)?

Machine safety is the basis for safe cooperation between man and machine – and a complex field of tasks. This is because many standards and guidelines have to be considered. These include the Machinery Directive and its associated standards, the Low Voltage and EMC Directives, directives and standards that apply when exporting outside, and the regulations that apply when modernising and converting existing machinery. Standards are defined by ISO & IEC, which are globally accepted & followed to define compliances. We have a tec.nicum division which takes care of safety services. The aim is to develop and implement the best possible safety solution for the individual application. We refer to global safety standards and applicable legal regulations of the respective region while conducting machine assessment activity.

With the global OEM market becoming more interconnected, how does Schmersal cater to different regional safety requirements?

With the global OEM (Original Equipment Manufacturer) market becoming more interconnected, we take a multi-layered approach to cater to regional safety requirements while ensuring global compatibility.

Schmersal Group, founded in 1945 in Wuppertal, Germany, is marking its 80th anniversary. It is represented by eight manufacturing sites on three continents, its companies, and sales partners in more than 60 nations. Due to our global approach, we help with safety requirements from locations around the globe.

Our adaptability, international certification strategy, and local presence make us an ideal partner for OEMS navigating a complex, globally regulated landscape.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.