We will be integrating our machines with Alexa

By OEM Update Editorial August 1, 2022 12:46 pm IST

Debabrata Chakraborty, OEM Sales & Marketing Head, Pakona Engineers (I) Pvt. Ltd., says digitalisation is essential since it allows a customer to know when and what their machine needs, thereby it becomes easier to manage the machine.

When we don’t use any keys for starting our cars, why do we require keys to start our machines! We are already working on it. By the next edition of Excon, we will have this new product ready.

What are the latest technologies employed at manufacturing facilities?

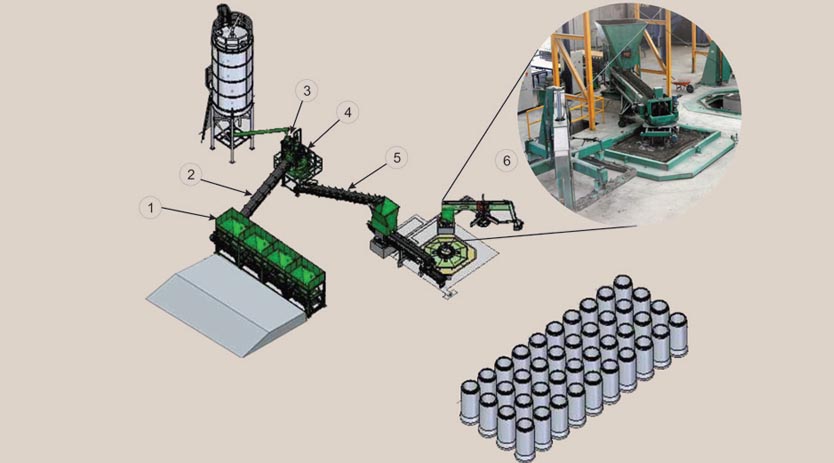

Pakona engineering has its CNC machine; all the machines we use, like laser technology, are full of automatisation. We also give the customer our software when it comes to batching plants. That is how we do it; our factory makes all the raw materials in India. Therefore, servicing becomes easier. The other day when we were interacting with a few government officials, they said more than access to innovative machinery, getting after sales and service has become an issue. So our strength is in our in-house R&D team and our facilities. We have all the spares and everything that has been manufactured with the vibrator technology, the Precast technology. So, that is how we are coping with new trends. We can customise certain products for our customers.

Is digitalisation impacting the manufacturing process?

Digitalisation is essential. Shortly we’ll be integrating our machines with Alexa. When you say hey Alexa, start my machine, the machine will start. This is what the new age customers require. When we don’t use any keys for starting our cars, why do we need keys to start our machines? We are already working on it. By the next edition of Excon, we will have this new product ready.

Moreover, if a customer knows when and what their machine needs, it becomes easier to manage the machine. So we are also working on those lines. The customer on the dashboard will know when it’s time to replace certain parts when oiling needs to be done when it’s time to do the auto greasing. So, implicate in this industry, especially in the segment to which we cater, the customers tend to ignore certain maintenance activities, and then the downtime affects them. So digitalisation is going to help them.

What kind of challenges do you deal with in the manufacturing process?

Internally, there are no such supply chain constraints as most of the things are made in India, and all the raw materials available that we are manufacturing. Still, the price of steel is impacting the overall pricing. If you have to export, then competitiveness becomes an issue. Three months post a quotation agreed upon, and the price does not remain valid because of the enormous variation. So that is the challenge we are facing, and from the customer’s perspective, the prices of overall raw materials of cement and steel are not helping, so a few projects are paused for the time being. So these are the hindrances.

In the context of the government celebrating Aatmanirbhar Bharat, how CII Excon expo is encouraging Indian OEMs?

This time at the Excon expo, majorly Indian companies demonstrated their capabilities. We have customers all over India who come to witness the event because this is the largest platform to interact with all OEM manufacturers. Customers get access to us, and we get access to customers from remote locations like Leh and Ladakh. We understand each other, go back to the drawing board, and alter certain modifications. As I have said, we have never thought a machine has to be established at a certain altitude like Leh and Ladakh, where we need to modify our equipment. Certain truckloads cannot be accommodated due to the hilly terrain. So we have to make it a smaller truck size. I think the Excon expo next edition would be far better. Far more participation is expected because people were excited. And postCOVID fatigue is slowly going down. So next time, it should be bigger and better.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.