Hazardous substances: How to minimise the dangers

March 31, 2020 5:46 pm

Hazardous substances are around us all the time. They include gas, liquid fuels, hazardous chemicals, solvents, paints and electrical components of industrial machinery, as well as consumer electronic products. Chemical manufacturing plants and industrial laboratories store large quantities of flammable materials on their premises at any given time. They pose great risk of fire and present a variety of hazards, particularly when safety is compromised while handling or storing them. At times, they can result in loss of life and cause irreversible damage to property and the environment.

A growing demand for energy, particularly in heavy industries, as well as proliferation of electrical and electronic equipment, have contributed to many incidents of fire in commercial premises. Material recycling centres also face new challenges in relation to fire risks. Hazardous vapours emitted by various products in a recycling process also carry a risk of fire. Kaushal Vora, Fire Safety Auditor, British Safety Council India talks about these risks in detail and discusses measures on how to reduce such risks.

Causes of fire

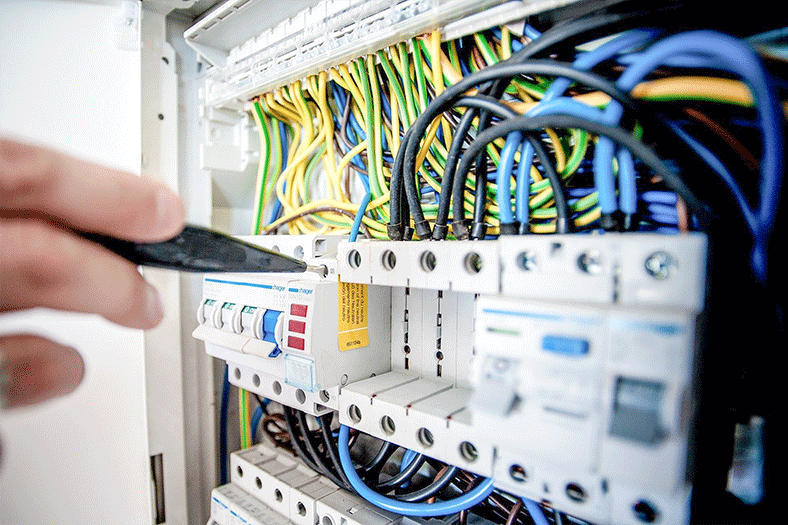

Although there are many different causes of workplace fires — from flammable materials being ignited to electrical equipment overheating — many are the result of human mistakes, such as poor planning and carelessness, or system failures. For example, fires caused by faulty wiring can usually be prevented through regular inspection and maintenance of electrical equipment. This is why the British Safety Council India has a Fire Safety Management Audit in place which helps organisation to improve their policies, procedures and protocols for effective management in fire prevention (https://www.britsafe.in/audit-and-consultancy/audits/).

For a fire to start, three essential components are needed: a source of ignition, a fuel source, and a supply of oxygen. Possible sources of ignition include heaters, light fittings, electrical equipment, cooking equipment, smokers’ materials (such as cigarettes and matches), arson and anything that can get very hot or cause sparks, such as machinery or welding and grinding work. Possible fuel sources include wood, paper, plastic, rubber, foam, packaging materials, textiles, display materials, furniture, plastic and timber storage units, waste, and flammable liquids, chemicals and gases. Sources of oxygen include the air, air conditioning systems, and medicinal or commercial oxygen supplies — for example, in cylinders.

If a fire breaks out, people can suffer burns or smoke inhalation, both of which can prove fatal. Smoke can also quickly travel ahead of a fire and block escape routes, trapping people in the danger area. Very often, fires break out in garbage dumps as a result of careless disposal of industrial waste materials. Personnel working in such places should be trained to segregate and dispose waste in a safe manner. They are likely to be directly affected by a fire, but they are often least prepared and least educated about it. They include garbage pickers, truck drivers, and waste handlers.

Hazardous substances may also go up in flames during transport. They are often transported by road in tankers and storage lorries that make very long journeys across the country in the scorching sun. Drivers and cleaners maintaining these vehicles should be well trained about the hazards of these materials and what to do in case of emergency. The vehicles should clearly display signs that they are carrying hazardous materials to caution other users of the road.

Storage of hazardous materials

The importance of safe storage of hazardous materials cannot be overemphasised. The areas where they are stored should be clearly demarcated. Standard operating procedures preventing unauthorised entry into such storage areas should be communicated to anyone who is likely to come into contact with them in course their work. Periodic checking by authorised personnel is very important. Areas where volatile materials are stored should also be checked for accumulation of vapour and, if necessary, it should be released in a controlled manner at specified intervals.

Case study

On 14th April 1944, during the Second World War, a manmade disaster of an unprecedented magnitude took place in India as a result of negligence and lack of safety awareness. A ship docked at Victoria Dock of Bombay (presently Mumbai) carrying a mixed cargo of cotton bales, gold, and ammunition, including around 1,400 tonnes of explosives, caught fire as a result of the negligence of a crew member. The fire engulfed half of Mumbai, taking the lives of about 1,300 people working at the dock, 500 civilians, 71 firemen and approximately 80,000 homeless people. The power of the explosion broke windows in a 12-kilometre radius. It destroyed three Royal Navy ships, and 50,000 tonnes of shipping got damaged. Two explosions created earth shocks which were felt in Shimla. Two square kilometres area got engulfed in fire within seconds from the first blast. It took 8,000 people to clear 5,00,000 tonnes of burned debris and clean the port. Every year, the week of 14th April is commemorated as Fire Services Week.

This example illustrates the magnitude of destruction caused by unsafe storage of hazardous material and ignorance of basic safety rules. These considerations are particularly relevant today in India, where industrial growth has reached an all-time high. Chemical and manufacturing units deal with huge quantities of hazardous materials and employ large numbers of permanent and contract staff, all of whom should receive basic fire training.

Fire prevention and handling hazardous substances

Adopting basic fire safety rules and practices is an essential requirement of any modern enterprise. Regular fire inspections and audits of the existing fire systems and fire-fighting equipment, availability of personal protective equipment, as well as regular inspection and maintenance of fire escape routes and emergency lighting are just some of the elements of a modern fire safety system in the workplace.

In industrial establishments, personnel responsible for fire safety should be provided with fire-resistant outfits. Fire alarms and lifesaving equipment should be inspected and tested regularly. Their volume should be set at a level audible to all staff who may be engaged in a variety of jobs. Regular fire drills must be conducted, and the entire workforce should be taught the fire procedures and steps to be taken when the fire alarm goes off. Each department should have a designated area to assemble when evacuating from the scene of risk. One member from each department should be charged with the responsibility of taking a headcount and ensuring that all staff is accounted for. The “safe” areas designated as temporary shelters should be located away from any toxic material. Escaping personnel should not be allowed to block exit ways or hinder movement of other staff or the emergency services.

A company’s staff must be aware of who the fire wardens in the company — the personnel designated to deal with the fire once it begins — are. They should be well-versed with operating a fire extinguisher and familiar with the location of the fire extinguishers on the premises. Although untrained staff must not be required or expected to attempt to extinguish a fire, all staff should be made familiar with the location and basic operating procedures of the fire-fighting equipment provided, in case they need to use it. If employees with fire safety duties are expected to use firefighting equipment when it is safe to do so, they must be trained in its correct use.

All fire precautions and equipment — including alarms, extinguishers, emergency lighting, safety signs, fire exits, and fire doors — and the fire separating elements designed to prevent fire and smoke entering the escape routes must be adequately maintained in good condition. It is advisable that large commercial establishments be fitted with fire extinguishers every 50 metres or so. In large plants that are centrally controlled, the person operating the mains must immediately cut off the power supply to the entire plant as soon as the fire alarm is sounded. These requirements apply to all the employees of the company — permanent employees, as well as contracted and casual staff working on the premises.

With so many workplace activities and materials posing a fire risk, it is essential that those in charge of industrial, commercial and public buildings identify the fire hazards and risks present and do all they can to reduce the risk of a fire occurring. Employers must also ensure they have adequate fire precautions in place, such as fire alarms, escape routes, fire safety signs and fire-fighting equipment, so that in the event of a fire, everyone can safely escape. By following these steps, business owners can help to make their buildings and sites safe for everyone — and help to reduce the number of injuries and fatalities caused by fire.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.