Inductive moulds pre-heating: no more open flames inside plants

By OEM Update Editorial January 12, 2024 7:54 pm IST

Metal forming is an ever-changing world, with innovations in materials and alloys that lead to new requirements in production processes. However, mould pre-heating is often carried out with obsolete and unsafe techniques.

Traditional mould heating methods

Mould pre-heating requires continuous supervision of specialised personnel, and they have several safety disadvantages: Induction furnaces, despite their efficacy, involve risky handling of hot and heavy moulds, coupled with their bulky, expensive nature. Open flame burners, while common, present enormous dangers due to the use of combustible gases indoors and fail to ensure uniform mould heating.

Other alternative methods do not present safety issues but usually have long warm-up times or very low heating temperatures.

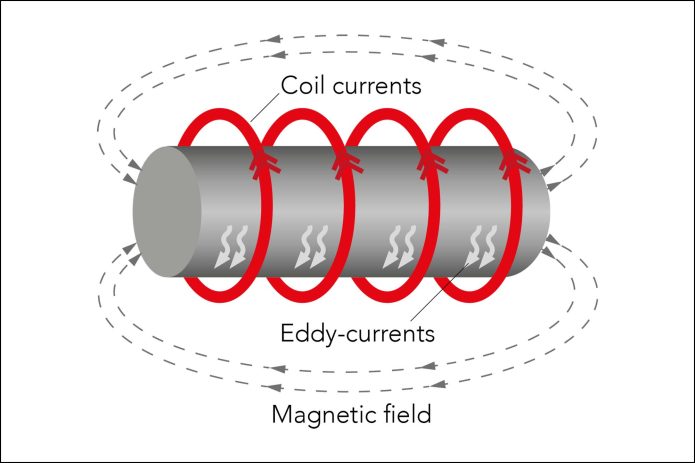

The principle of electromagnetic induction

Magnetic induction transfers energy safely and efficiently from a coil to any ferromagnetic material. The energy transferred to the target is transformed into heat, directly generated in the metal itself. This allows for the maximisation of heating performance compared to any other method, thus avoiding energy waste.

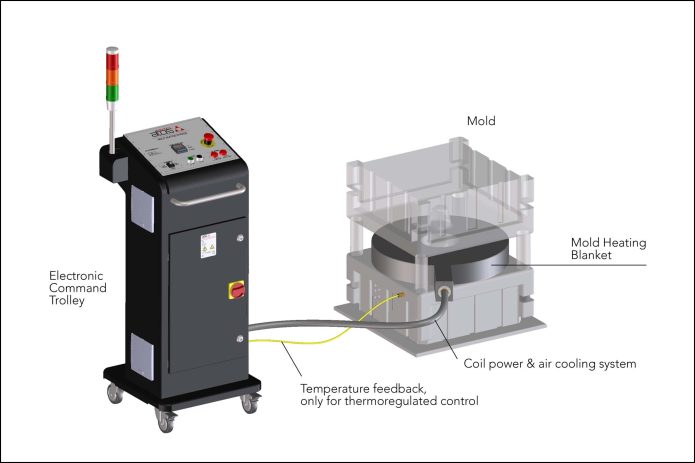

Inductive technology in moulds pre-heating

Atos Induction has exploited the benefits of magnetic induction to create a patented innovative induction heating method dedicated to metal forming. The induction moulds’ pre-heating system consists of a flat coil powered by a control system that manages the heating process.

This innovative solution overcomes all the disadvantages of traditional heating methods by safely using induction heating. The solution improved traditional heating methods by employing induction heating blankets, mitigating various drawbacks. It reduces heating time by minimising thermal inertia and expediting heat transfer. With inherent energy efficiency, it ensures optimal use of power. Moreover, it achieves uniform heating by directly generating heat within the material. The system offers automated control, either timed or temperature-regulated, eliminating the necessity for constant operator supervision. Its user-friendly nature requires no specialised skills—simply placing the blanket on the mould surface initiates heating. It prioritises safety by eliminating combustible gases and open flames during operations.

Atos Induction’s patent presents an innovation in occupational safety within the moulding industry, making it possible to eliminate the use of hazardous and increasingly expensive combustible gases.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.