Helping you to the finish

By OEM Update Editorial January 10, 2017 5:31 pm IST

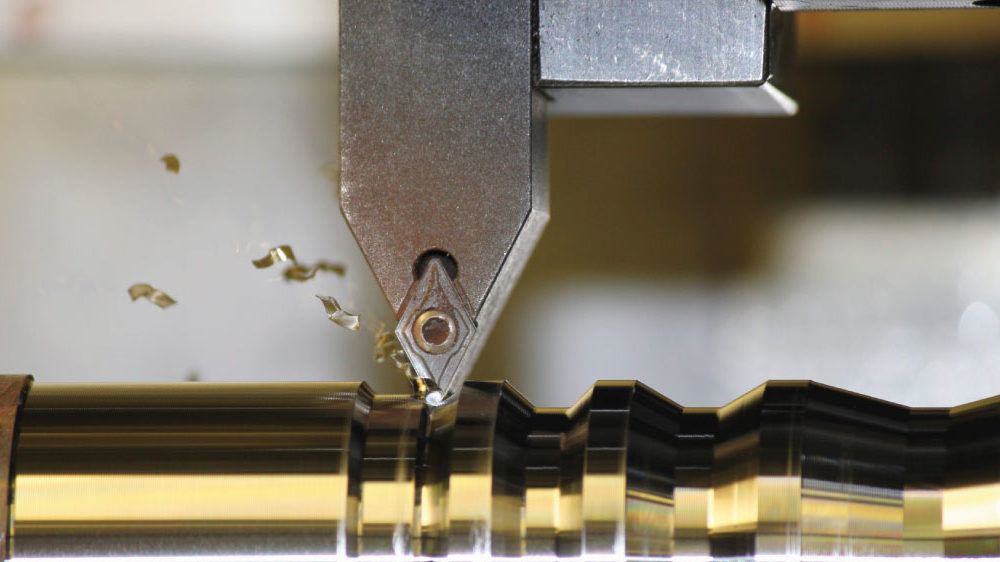

Dormer Pramet has launched several new inserts and a grade to support turning in specific materials

The new chip breakers – developed under the Dormer Pramet’s Pramet brand – target finishing and medium to roughing turning operations in steel and cast iron, high temperature alloys and stainless steel.

Firstly, the NF1 and NF2 positive chip breakers support turning applications in stainless steel. The balanced shape of these new inserts offers excellent chip control, with low cutting forces promoting both high durability and productivity.

The NF1 is a universal chip breaker for finishing to medium machining, peripherally ground to provide a very good surface finish. The versatile NF2 chip breaker incorporates a small stabilizing T-Land and covers a wide range of applications from semi-finishing to light roughing.

Pramet’s new FF2, FM2 and RM3 inserts for steel and cast iron provide very good chip control at low feed and depth of cut with a high quality machined surface finish.

The FF2 chip breaker has a positive rake angle and depth of cut from 0.15mm for fine finishing applications in low carbon steels. The FM2 chip breaker is for finishing to medium machining with depths of cut from 0.2mm. Featuring a protective land, it is suitable for continuous and interrupted operations.

The highly resistant RM3 chip breaker is for roughing applications in steels and suitable for unfavourable machining conditions.Finally, Pramet’s new SF2 and SF3 positive inserts provide a highly secure and dependable option for turning applications in high temperature alloys. The SF2 chip breaker is for fine turning at the lowest possible feeds, while the SF3 chip breaker with its positive inclined cutting edge supports finishing operations.

Especially effective when used on small and slender components, both inserts offer a sharp cutting edge with minimal radius. This promotes low cutting forces which, in turn, prevents work hardening and ensures a high quality surface finish.

Meanwhile, in addition to the new assortment of inserts, a new grade for turning stainless steels has also been launched.

The T7325 grade becomes the first choice for productive machining of stainless steels. It has been developed to complement the existing T7335 grade, which is recommended for use in unstable machining environments.

Also suitable for interrupted cutting, the latest T7325 grade features a functional gradient substrate and special MT-CVD coating. This combination offers high cutting strength, reduced built-up edge and resistance to the formation of cracks. As a result, the grade provides a high level of operational reliability, performance and tool life.

For more details contact your local Dormer Pramet sales office or visit www.dormerpramet.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.