Smart EMS can reduce energy wastage and lower carbon footprint

By OEM Update Editorial June 9, 2023 2:45 pm IST

Sustainable manufacturing while reducing wastage is the primary motivation for factories to become increasingly profitable, feels Upendra Vanarase, Managing Director, Trio Motion Technology India Pvt. Ltd.

How does Trio Motion Technology’s range of motion control solutions cater to the specific needs of OEMs?

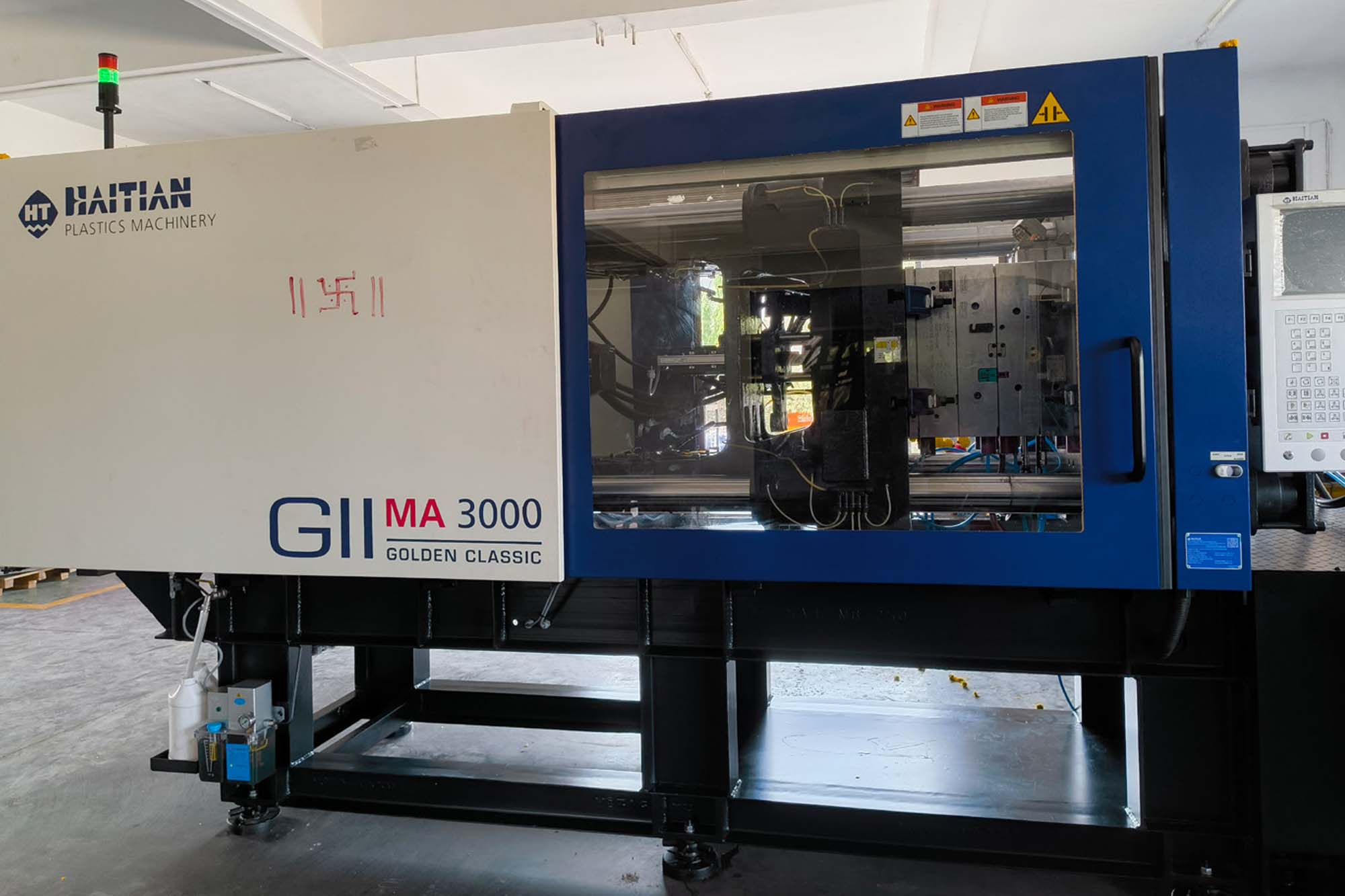

Trio Motion is dedicated to providing innovative motion control solutions that help our customers improve their machine performance, productivity, and reliability across various industries. Trio Motion Technology has manufactured high-quality motion controllers branded Motion Coordinators since 1987. It has a comprehensive range allows economical, flexible, and seamless control of 1 to 128 axes of servo motors, stepper motors, piezo motors, or hydraulic systems. Trio products can be found in virtually every servo and stepper application.

Our range of Motion Coordinators, Expansion Modules, I/O Modules, Servo Drive Systems, and HMIs are designed to enable the control of industrial machines with a minimum of external components. Trio’s range can be combined in many applications to build a control system capable of driving a multi-axis machine and all its auxiliary equipment. Our systems are designed to meet the needs of diverse applications, from packaging to robotics and industrial automation. Our commitment to quality and sustainability is reflected in our ISO 9001:2015 certification and our products energy-efficient features.

One of our key strengths is that our company specialises in designing customised solutions for Original Equipment Manufacturers (OEMs) and producing motion control options compatible with drives available worldwide. Additionally, we license our designs and technology to various automation firms. Our products can be obtained through our extensive network of distributors and drive experts who provide local technical support and training.

How your range of technology solutions has contributed to enhancing manufacturers’ performance?

Automation and robotics have enabled repetitive tasks to be carried out precisely and improve productivity. IIoT enables manufacturers to gather real-time data from machines, providing insights into performance, usage patterns, and maintenance requirements, leading to process improvements, reduced downtime, and increased profitability. AR and VR technologies provide real-time guidance and simulation, improving productivity and throughput while reducing downtime. Next-generation advanced technologies can predict maintenance requirements, identify inefficiencies, and optimise production processes, improving product quality and profitability.

We are committed to helping our customers leverage technological advancements to achieve their performance goals. Our range of motion control solutions, including motion controllers, servo drives, and integrated control systems, are designed to enable our customers to improve their machine performance, productivity, and reliability.

What latest advancements have occurred in motion control and robotic technology to optimise performance?

Trio Motion is committed to staying at the forefront of the latest control, motion control and robotic technology advancements. Innovation is critical to meeting the evolving needs of our customers, providing solutions and helping them improve their productivity and profitability.

Our ‘Motion Coordinator system’ is highly modular and allows users to tailor the controller to their needs. This also allows the flexibility to incorporate new modules if the need should change, making the system scalable and “future-proof.” This feature enables our customers to optimise their machines for maximum performance and efficiency, increasing profitability.

How have your intelligent solutions helped OEMs and factory operators to reduce material wastage?

The importance of sustainable manufacturing practices is growing daily, and technology plays a crucial role in reducing waste and energy consumption. Sustainable manufacturing while reducing wastage is the primary motivation for factories to become increasingly profitable. Our energy-efficient servo motors, drives, and control systems are designed to help our customers achieve their sustainability goals by reducing energy usage and increasing operational efficiency. With our innovative solutions, we aim to help manufacturing units reduce their environmental impact while improving productivity and profitability. Our intelligent solutions have helped OEMs and factory operators drastically reduce material wastage.In what ways does technology aid in optimising resource utilisation and reducing environmental impact?

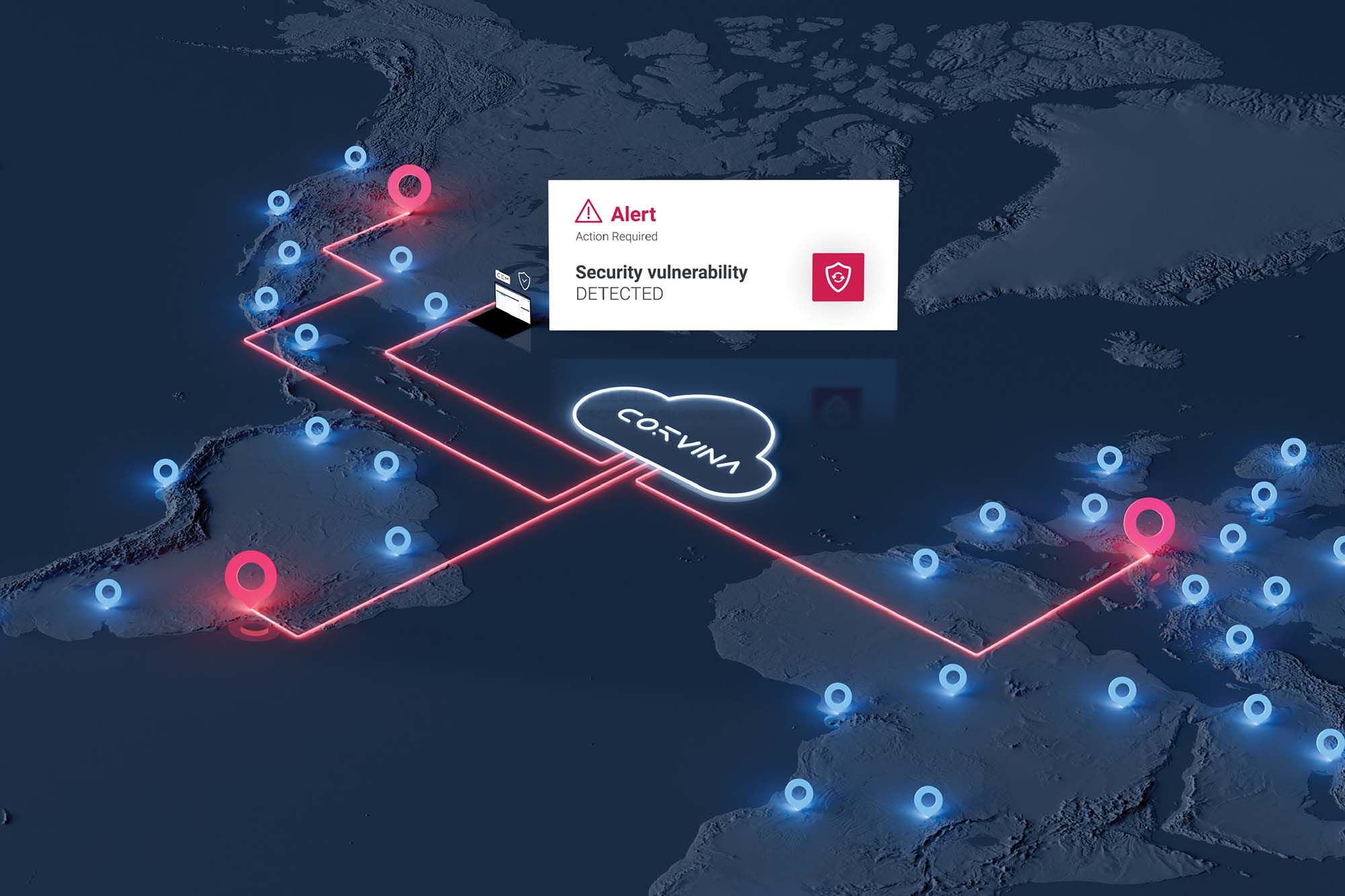

One way technology can aid in optimising resource utilisation is by deploying predictive maintenance and real-time monitoring coupled with business analytics. Advanced software and sensors allow machines and lines to anticipate equipment malfunctions and arrange for maintenance measures before the equipment fails. This drastically reduces the possibility of untimely breakdowns decreasing periods of inactivity and stopping production, thus, reducing wastage. Another way technology can aid in reducing environmental impact is through energy management solutions. Organisations can reduce energy wastage and lower their carbon footprint by implementing smart energy management systems that analyse and optimise energy usage. Additionally, organisations can leverage technology to analyse data and identify areas for improvement. Organisations can identify patterns and trends, make informed decisions, and take steps to reduce their environmental impact by tracking and analysing energy usage data.

What measure do you adopt for upskilling the workforce and training to achieve production efficiency?

Upskilling and training help enhance the knowledge and skills of the workforce and enable them to adapt to new technologies and production processes. Trio Motion India offers training that aims to provide an introduction to programming and give an overview of our entire product range. Our introductory course is based on practical examples of each topic covered, allowing attendees to gain hands-on experience using Motion Perfect to develop applications. This training benefits those currently using Trio’s products or considering them for the first time. Additionally, Trio offers tailored courses for experienced programmers and customers requiring specialised or advanced training.

Our trained and expert applications engineers help provide in-depth knowledge to our customers. Moreover, our packaging template is an outcome of decades of our employee’s expertise, making the life of our customers easier.

We are improving our workforce’s skills and helping our customers achieve optimal performance and efficiency in their production processes by providing training and upskilling opportunities. This also contributes to a sustainable manufacturing process, as a well-trained workforce can adapt to new technologies, improve productivity, and reduce waste.

What is your company’s approach to sustainable manufacturing practices?

We understand that sustainable manufacturing practices are crucial in reducing the environmental impact of our operations. Therefore, we actively approach sustainable manufacturing by engaging with our suppliers and customers to promote sustainable practices throughout the manufacturing process. The entire manufacturing industry can work together to reduce our collective environmental footprint by aligning our entire ecosystem with our sustainability goals.

What are your company’s key initiatives?

As a motion specialist, Trio Motion India has a clear vision to provide innovative technical solutions and 24*7 customer support to breathe life into machines. In line with this vision, the company has future initiatives to strengthen customer intimacy and help Indian machine builders develop smarter and more reliable machines.

One of the key initiatives is to provide optimised control technology that can increase machine throughput and performance. This will enable Indian machine builders to meet the growing demands of end-users and stay competitive in the market.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.