By 2020, we should become a dependable force to reckon with

By admin June 16, 2010 5:33 am IST

“The steel industry has unfortunately, in my personal opinion, received step-motherly treatment from the Government of India by way of their policies. I am sure we will take note of past mistakes and initiate corrective measures by way of proper policies that benefit the entire population of our great country. The industrial manufacturing sector is gaining ground and I see a very bright future in the years ahead”, said RK Markan, CMD, H&K India in an exclusive interview with OEM Update.

First of all, congratulations on celebrating the 25 years of H&K India’s service. Please brief us about the journey of your Company from its inception to where it stands today.

Thanks a lot. 25 years for H&K India is indeed a moment to treasure and reflect on this long journey, more so because it also marks 48 years for me in the steel industry – an industry that is a very tough one for survival anywhere in the World. It is heartening to note that from a small and humble beginning with a capital of Rs 10,000 we have today come a long way in being instrumental, after crossing many hurdles, in raising the standards of the Indian rolling mills and in bringing about a change in the civil construction sector by ensuring that they use proper quality of steel rebars in RCC works, as against what has been in use in India since 1970 (CTD rebars) – even though their usage had stopped globally nearly four decades ago on account of their poor properties. It had become our obsession that India too gets proper steel reinforcement for all civil construction.

What were your prime objectives behind setting up this business and how much you have been able to achieve so far?

When Wolfgang Kluetsch and I started H&K India in May 1985, we had outlined our main objectives as:

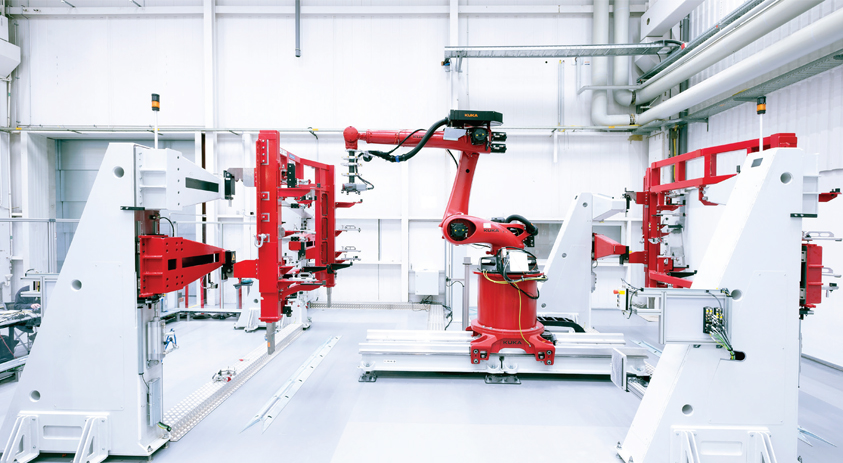

• Raise Indian secondary rolling mills to global levels through use of modern technologies and equipment

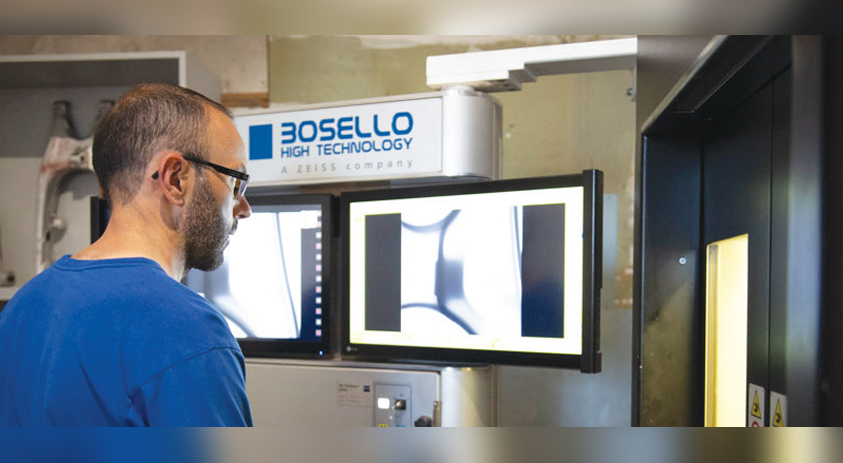

• Introduce the patented Thermex Quenching & Self Tempering Technology for production of international grade of rebars in India

• H&K India to focus on technology and quality of service instead of the common practice of focussing on profitability – we believed if we were on the right path and were honest to our profession, money would follow in the long term.

I am happy to state that we did not stray from our stated objectives in spite of the long wait for acceptance of our ideologies. We now note a trend amongst Indian mills to adopt only modern mill practices. Additionally, about 65 per cent of rebars produced in the country are through the THERMEX Quenching Systems installed by us. This is extremely satisfying.

Can you tell us about H&K’s contribution to the Indian industry?

Quite a lot really. There have been many ‘firsts’ for us during this 25 year period. In this list we can include ‘stop-start’ shears, trough & grip tilters (as against manual handling) to permit use of larger billet/bloom weight resulting in improved yield and the automated bundling & binding systems for high production levels in upgradation of steel rolling mills.

Finally, the unique THERMEX Quenching and Self Tempering technology and system for production of rebars of global standards – very important for ‘seismic’ India. This has broken the 40-year stranglehold of ‘Torsteel’ and CTD rebars in the country. The civil engineering sector has conferred on me a few ‘Life Time Achievement Awards’ in the field of steel reinfor cement at numerous International conferences for this “awakening”.

You are into the business since last 25 years. What is the current status of Indian rolling mills industry? Where does it stand in terms of attaining international quality?

As against an average 40,000 TPA capacity and manual operations when we started, today we note that most of the secondary mills are looking at a viable capacity of 100,000 TPA or more with upgraded technologies at par with rest of the world. That is a healthy sign but a lot remains to be done even today because we do not have requisite trained engineers and skilled workers with relevant experience. I am however confident we shall soon catch up with the rest of the world.

What are the prime barriers in expanding the growth of rolling mills industry and how these issues can be resolved?

The steel industry has unfortunately, in my personal opinion, received step-motherly treatment from the Government of India by way of their policies. Any nation’s standing in terms of development can easily be ascertained by the per capita steel consumption and we ranked in the ‘under-developed’ category of nations (less than 50 kg) as recently as 2005. Since 1990 when liberalisation begun, we were only introducing policies to benefit the 30 per cent urban population with scant regard for the rest of the citizens. Thus, we jumped to becoming a consumer society, on account of the large 300 million middle class markets without going through the basic steps of industrialisation. Consequently, IT and computers were given a boost instead of paying heed to the basic infrastructure needs and today we are playing ‘catch up’ – as I often say, “we got the cars before we got the roads”. China took a different path during this period by giving priority first to industry and infrastructure and later to IT and computers. As a result of their policies, their per capita steel consumption is just over the 250 kg level – the transition level from developing to developed category. A few decades earlier their steel consumption was below India’s. Clearly we have missed the bus and now we urgently need to set matters right.

In 2003 I had ventured to suggest, at an international conference, that India must raise its steel consumption to 200 million tonnes by 2020 but was promptly ridiculed by the captains of the steel industry. Today, they are talking on the same lines but we are now facing the menace of the ‘red corridor’ (on account of earlier faulty policies of neglect) in the regions of Chhattisgarh, Jharkhand, Orissa, Bihar and parts of West Bengal, Maharashtra and Andhra Pradesh. Instead of India’s development, our IIMs, IITs and IT industry was busy since 1990s in further developing the advanced countries and the government was happy merely with our rising FE reserves.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.