Digitisation: A gradual step towards digital transformation

By OEM Update Editorial June 29, 2017 1:59 pm IST

Digitising processes at every level is improving the man-machine interface which increases overall productivity.

Ravichandran Purushothaman, President, Danfoss Industries shares his views on how well Indian players are empowered to design, modify and create products and solutions that customers are looking for which in further helps companies to explore new revenue opportunities.

Digital transformation: New future for the manufacturing industry

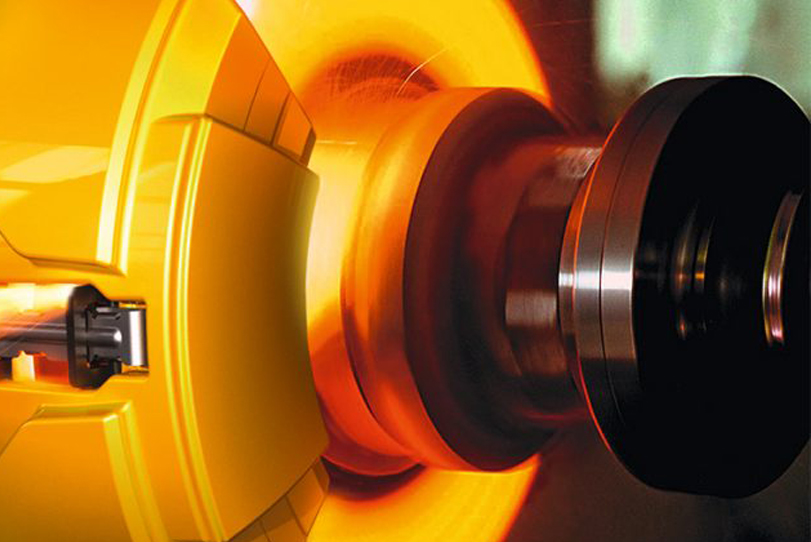

Digitisation is a gradual step towards digital transformation, which is the consequent goal. Digitisation to a large extent is blurring the lines between the physical and digital worlds, paving the way to a whole new future for the manufacturing industry; from the way in which products are designed, produced, shipped and finally, the way end-customers engage with brand, may it be B2B or B2C. Digitising processes at every level is improving the man-machine interface which increases overall productivity. This helps iron out all defects, delays and downtime and therefore, a dream come true to manufacturing players. In other words, this is the rise of the Industry 4.0 era in the making.

Here are some ways in which digitisation is transforming the manufacturing sector:

Flexible business model

While customers are becoming highly demanding and are asking for individualised, high quality products at a fast rate, it is important to manufacture as sustainably as possible. With digitisation, all departments are well integrated and the silos are broken while flexibility is retained.

Customer is king

The customer is always king. Whether one might be a B2B or a B2C business, Danfoss manufacture products to address certain pain points of customers. Digitisation makes this a lot more seamless by interconnecting all processes by simplifying man-to-machine communication.

Digitisation makes everything “smart”, paving the way to industry 4.0, where there are flexible business models; this means less waste and energy use, increased efficiency, fast turnaround, better quality, faster time-to-market, integrated supply chain and better security. In simple terms, one achieves operation excellence with smart manufacturing.

Scalability with innovation

With emerging and advanced technologies like Internet of Things, 3-D printing, big data and analytics, players are empowered to design, modify and create products and solutions that customers are looking for. This helps companies explore new revenue opportunities.

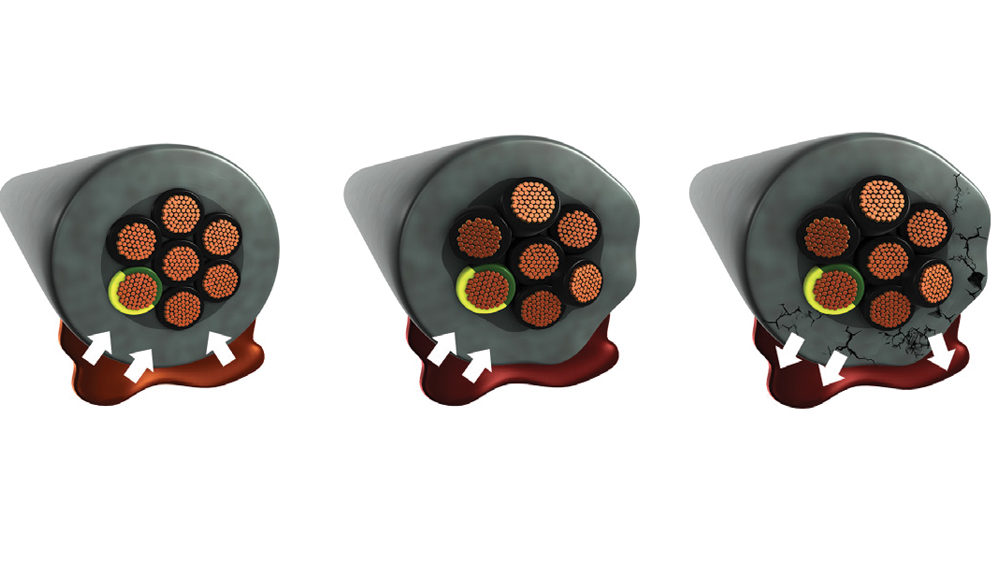

However, it is important to keep in mind that digitisation can be disruptive. It is fundamental that companies ensure that the golden triangle of change is ready to make the transition i.e. people (who are at the crux), processes (which require human intervention) and technologies (that help perform processes).

Principles for designing smart applications for user-friendly design

Danfoss products are designed for smart applications due to the user-friendly design focus that they have. This addresses the ease of use primarily. Customer-centric solutions have been the main architecture of the Danfoss design principles. The company has incorporated design thinking in its products

to ensure that helps customers connect to various devices and gain maximum value from our products and solutions.

Digitisation is a key transformational strategy

Danfoss is currently embarked upon over the last couple of years. Danfoss currently spend over 4.2 per cent of total sales as investments into R&D, under digitisation; they have several other initiatives where they are working towards providing the best-in-class digital customer experience for Danfoss customers worldwide. Moreover, Danfoss is also taking advantage of the digital technologies and some of the industry 4.0 focus areas to speed up and increase innovation and performance of the products. Digitisation has also helped them build capabilities in newer business models where they are able to add significant value to their customers, both from an energy-efficiency and safety perspective.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.