Making machine tools traceable throughout the lifetime

By OEM Update Editorial May 12, 2017 12:59 pm IST

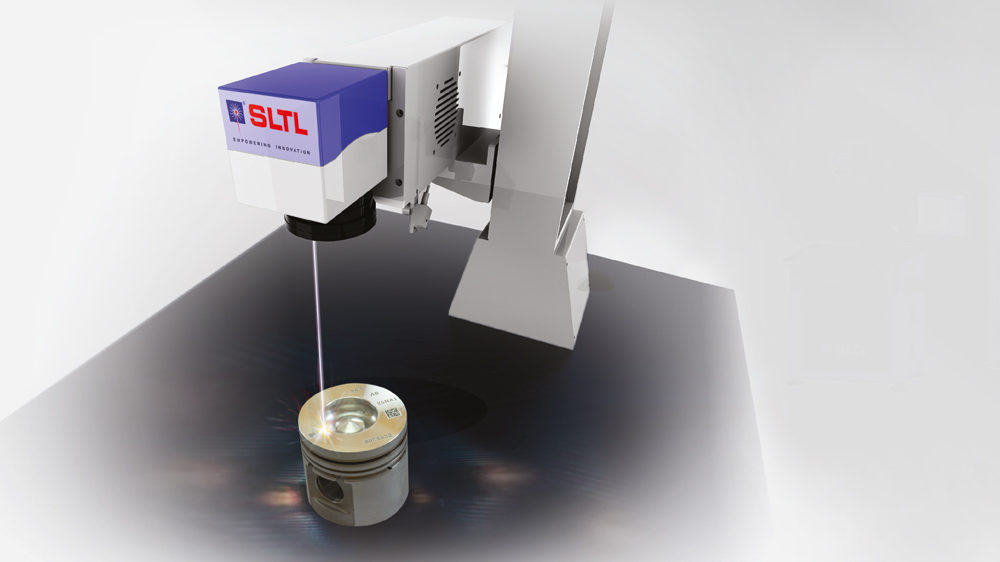

“Marking made by SLTL laser machine never fades away and remains crystal clear throughout the product life cycle”

India holds a great place in machine manufacturing industry; it stands at 13th rank in the production of machine tools and holds 10th position in its consumption according to the world survey conducted by Gardner Business Media in 2016. The country acquires top-notch machine tools manufacturing and it is on the verge of becoming a key player in the global machine tools manufacturing industry. The manufacturing industry is considered as mother industry, laying emphasis on ‘Make in India’ initiative.

With around 1,000 machine tool production units, the Indian Machine Tool Industry is flourishing at large scale. Almost, 75 per cent tool producers of India are ISO Certified and many manufacturers have also acquired CE Marking certifications for matching standards of European markets. Large-scale players serve to heavy and medium industries while the small-scale players cater the demand of ancillary and other units. Indian machine tool industry is developing at 12 per cent growth rate every year.

Further, machine tools industry in India also offers various opportunities for investment. In addition to that, there is still a requirement to increase the dimension of this sector. The industry has key user segments like automobiles, aerospace, consumer durables, machine manufacturing, etc. Tooling demand is at its top-level along with the high demand of plastic moulds followed by sheet metal dies and other types of dies.

Along with all these accomplishments, one of the most significant victories of machine tool manufacturing industry is that it plays a major role in government initiatives like ‘Make in India’ and ‘Skill India’. It is certain that machine tools industry has strategic worthiness for the Indian economy. Manufacturing segments like defence, railways, automobiles, plastic machinery, white goods and medical electronic cannot achieve high-level of innovation without strong machine tools manufacturing segment.

Machine tools sector is required to manufacture complicated tools in order to meet customised requirements of demanding user industries. Industry entails expanding investments in R&D, robust design, and innovation. Studies have indicated that India is comparatively more capable of manufacturing at large scale along with the availability of skilled engineers. Moreover, this industry holds a competitive advantage in terms of design strength and SPM tools. High demand for machine tools is estimated from intermediate goods sectors which include components like ball and roller bearing, auto, and electronic equipment production.

It is said that there are even opportunities in the ocean; inevitably countless opportunities are hidden in Indian manufacturing industry. With the right direction and appropriate investments, India has potential to become a manufacturing hub. As a matter of fact, a gradual hike is noticed in sectors like railways, defence, and aerospace. In order to remain in the competition and witness growth in manufacturing field, it is important to grab all spotted opportunities. We surely need to be much rapid along with one-stop clearance. With most reliable government policies and support, it is quite possible to do business in an efficient manner and transform ‘Make in India’ into reality. A glimpse of rising machine tools industry has been observed with an investment of Rs 100 crore by the department of heavy industries with the aim to boost the machine tools sector.

Maulik Patel,Executive Director,

Sahajanand Laser Technology Ltd.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.