Treating metal with high-velocity abrasive strikes of shot blasting

By admin February 7, 2023 2:29 pm IST

Air-operated and airless blasting systems are the two operating principles on which the blasting machines are manufactured.

The shot-blasting process in India has grown by leaps and bounds over the last three decades. The process was only sometimes as well-established as it is now. The most important single factor is that quality consciousness in the engineering and automotive industries has improved immensely, with many foreign companies putting up joint ventures or independent manufacturing bases to capture the ever-expanding Indian automotive industry.

Multinational companies already have the norms for shot blasting to maintain the quality parameters usually associated with domestic industrial and automotive products. But most Indian manufacturers were obligated to use the refined process, particularly the preparation techniques in general and surface shot blasting.

In most cases, the old, trusted seven-tank surface preparation process was forced to be shifted to the shot blasting process to take up the pollution control needs of the country. It was also observed that the operating cost of shot blasting had given a clear edge to the established users of Indian Automotive Industries if parameters like space are required for putting up an ETP plant to support the seven-tank type. The very nature of the shot blasting process that keeps it in the category of the green process is yet another factor which keeps it moving ahead in the Indian industry at a faster pace.High-velocity abrasives strike

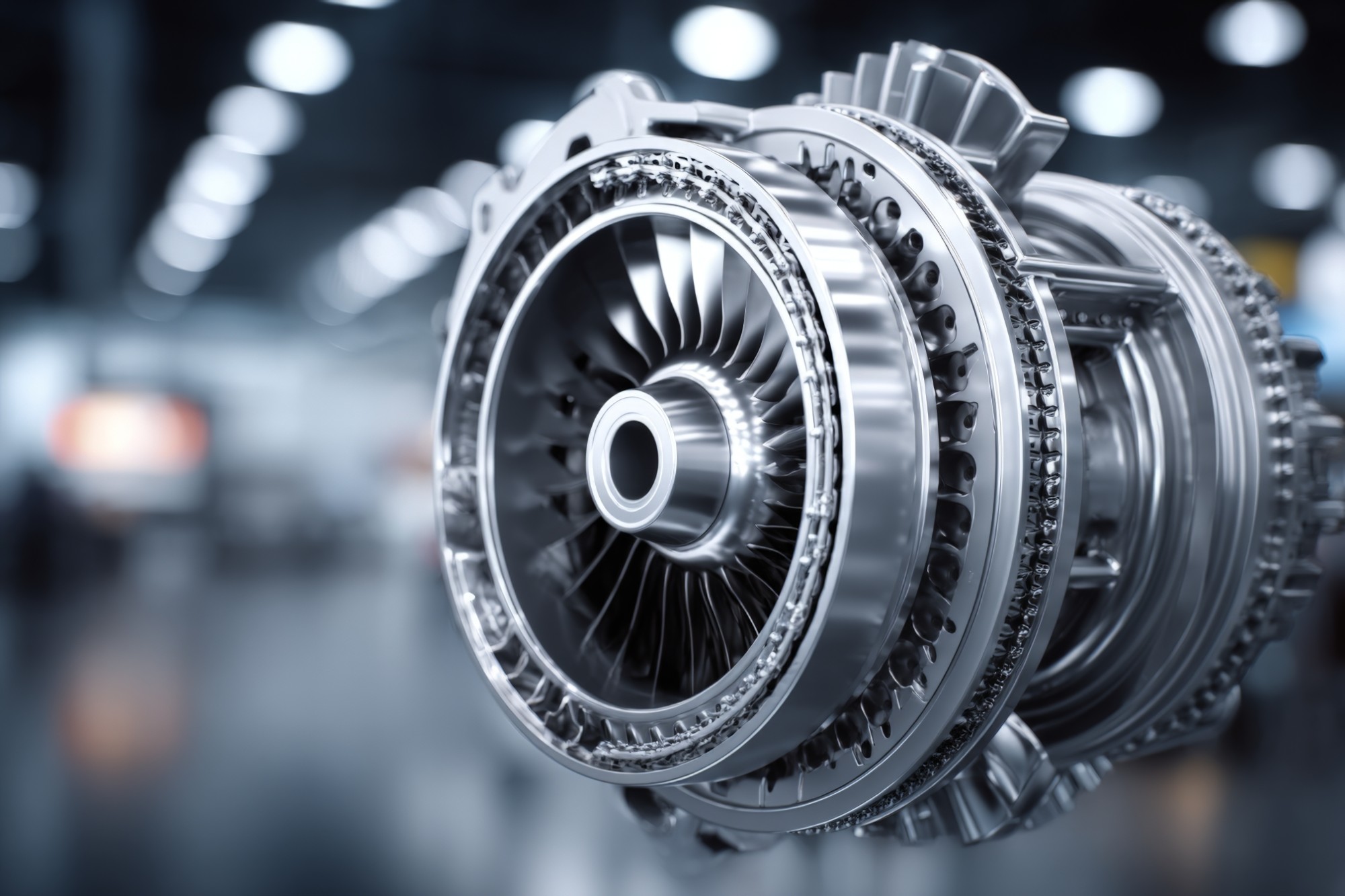

Shot blasting is an impact treatment process where high-velocity abrasives strike the substrate to remove the foreign material, scale, rust, etc., and produce a rust- free base metal. This is good for further surface coating processes like painting, powder coating, or passivation lines. The abrasives used are of various types like steel shots, steel grits, stainless steel shots and grits. Many non-ferrous abrasives, like alumina, copper slag, etc., are also used depending upon the component to be blast cleaned, its size and weight, the quantity of manufacturing material to be handled per shift and the final surface coating requirements.

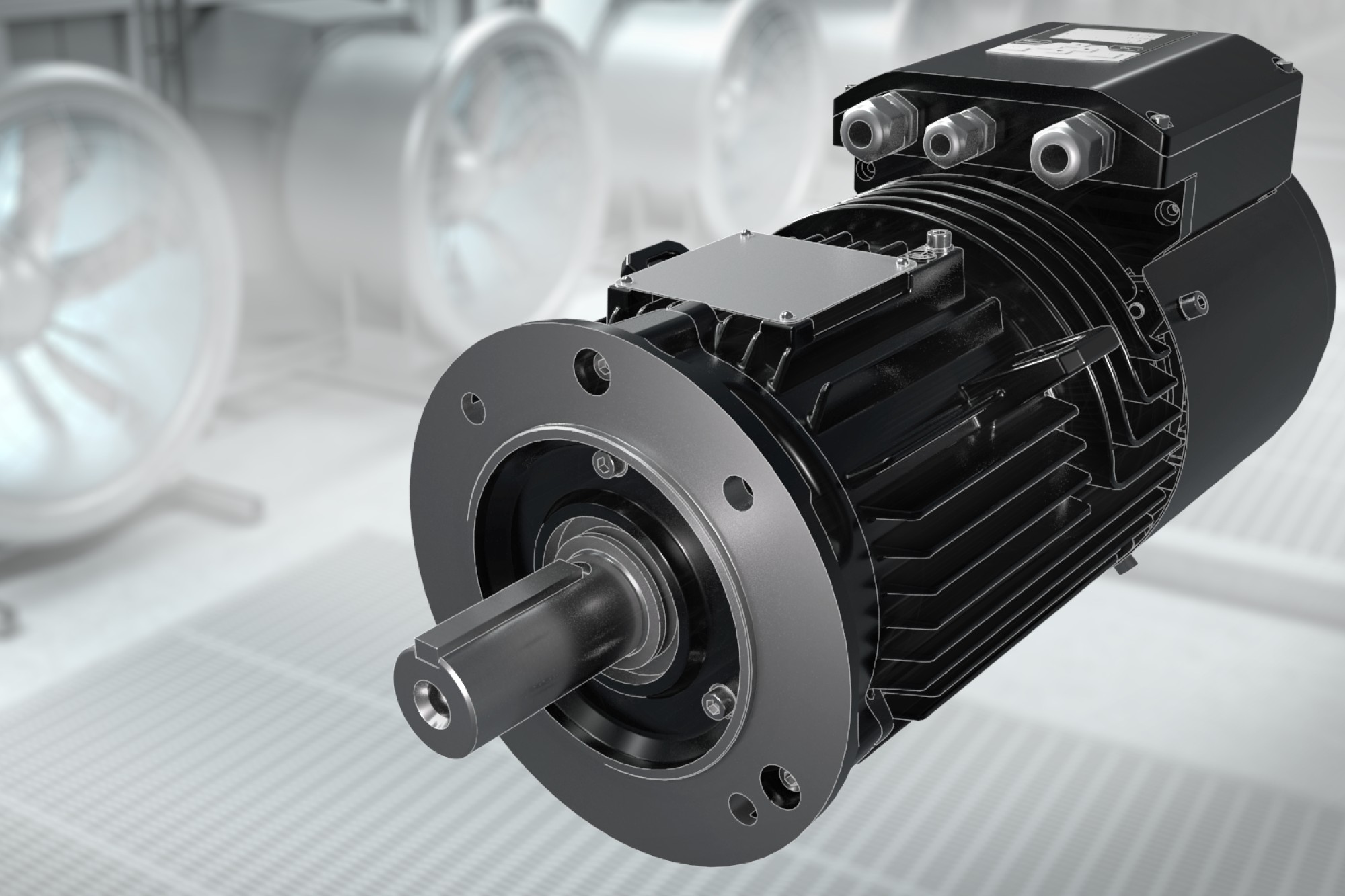

Air-operated and airless blasting systems are utilised to achieve this target. These are the two operating principles on which the blasting machines are manufactured. The air-operated system uses air pressure to propel the abrasive, whereas the airless blasting machine uses centrifugal blast wheels to propel the blasting media.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.