Digitising oil health analysis

By OEM Update Editorial July 17, 2017 12:21 pm IST

Automation and its context in a digitally connected world to measure oil health analysis.

Industrial (R)-EVOLUTION and its journey since inception

Industrialisation has been an ever-evolving phenomenon and can be defined as a gradual progression where manufacturing and industrial capacity was created or augmented and which became a driver to economic growth.

The first industrial revolution began in Britain in the late 18th century, with the mechanisation of the textile industry. This gave birth to the factory system where hundreds of weavers came together under a single roof in a mill.

The second revolution followed with the age of mass production, pioneered by Henry Ford where the assembly line was conceptualised and technological developments made way for economic development. This industrialisation came to be a period of a paradigm shift towards factories and mass production, powered machinery from the rudimentary hand tools or home based manufacturing methods that existed. This gave birth to a modern era and led to large scale urbanisation and a tectonic shift in living standards owing to advancements in transportation, banking and communication as well as large scale manufactured goods.

Then came in the third revolution where technology played a key role with mechanics being converged with computers to build a digital world of robots and processes; therefore the intervention of information technology – a disruption which everyone had to take cognisance of as well as adopt. This was characterised by high end technology, intuitive systems and monitoring which brought about more precision and better performance in production etc.

The fourth revolution or as we now know it is Industry 4.0. This is the next phase of digitisation where manufacturing has seen a shift towards the development of ‘smart factories’. This evolution requires greater levels of integration among information, communication, and manufacturing processes that we’ve never seen before.

Today, the need for flexible solutions and customised products has led to rising complexities in production; at the same time the need to maintaining efficiency while not compromising in quality has led manufacturers to a point where being globally competitive as well as optimising on energy, materials consumption etc. is paramount to ensure and maintain overall profitability.

As industries have evolved, so have the need for reimagining and redesigning the working processes. Herein, to accelerate efficiency and productivity manufacturers will need to invest in efficient technologies and automation solutions. With the world becoming more linked than ever before, a connected industry environment is the new rule of the day which has brought about the emergence of cyber- physical systems coming into play, giving way to the Internet of Things (IoT) and cloud computing; This is the next industrial revolution, viz. Industry 4.0 or the Industrial Internet of Things, viz. IIoT.

So what is Industry 4.0 and how can it help?

The Industrial Internet of Things (IIoT) also known as Industry 4.0 is the latest buzzword in industrial revolution. It encompasses all processes such as product design, manufacturing, services and refurbishment which are completely integrated and exchange information in real time. This revolution will transform the manufacturing processes in sync with the speed of change in customer needs – which implies, making the production process flexible without taking excess time.

IIoT offers a chance to redefine many sectors and accelerate economic and employment growth. However, to seize these opportunities, businesses and governments must intensify their efforts and escalate investments. As India progresses in its pursuit to become a preferred manufacturing destination, current practices have to make way for adoption of IIoT to enable industrial transformation. A connected enterprise significantly enhances decision making, increases security and productivity as well as improves overall collaboration across the enterprise by providing the right information at the right time, to help optimise operations.

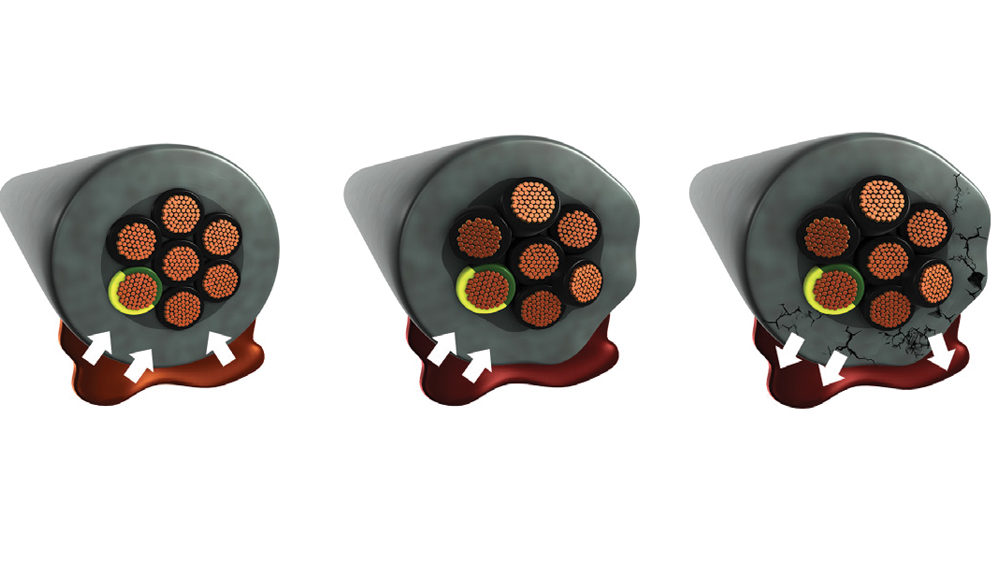

Digitising oil analysis data in manufacturing

Vertical system integration in Industry 4.0 digitises and integrates processes across the organisation. Data managed and analysed for operational planning, efficiency and quality management can be made available in real-time and optimised in an integrated network. Data analytics in vertical integration provides valuable insights that facilitates productivity and improves equipment maintenance. According to a PwC report, 82 per cent of companies in Asia Pacific expect data analytics to have a significant influence on their decision-making in five years’ time. This includes digitising oil analysis data to simplify and improve the paper-reliant process. The traditional oil analysis process is laborious and costly, and may cause unscheduled downtime and reduced operational efficiency. Companies unfamiliar with the testing process could encounter delays in production. Furthermore, the diagnosis from the analysis could also impact their productivity, safety, and environmental goals.

Industrial lubricant and greases makers have come to realise that their customers are shifting towards the Industry 4.0 model and are looking to help improve processes and increase efficiencies too. This is why companies such as ExxonMobil, who have a long history of working with equipment manufacturers, worked to develop a modern platform for an integral part of manufacturing: oil health and analysis.

Introducing Mobil Serv Lubricant AnalysisThe Mobil Serv Lubricant Analysis (MSLA) is a new mobile-enabled used oil analysis platform that was launched in Asia Pacific in July 2016. The new service is designed to enhance efficiency and simplify the oil healthy analysis process by replacing a paperwork-heavy approach with a simple, intuitive mobile-enabled service platform that reduces the number of steps involved in the used oil analysis process. MSLA is a solution manufacturers need to take to move towards Industry 4.0 and digitisation.

MSLA replaces ExxonMobil’s previous used oil analysis platform, Signum Oil Analysis, and is testament to the brand’s commitment to develop cutting-edge services that push the boundaries of efficiency and technology for customers.

The platform streamlines the entire oil analysis process – from initial sample gathering to final reporting, with QR coded scan-and-go sampling bottles that deliver used oil samples to ExxonMobil’s oil analysis laboratory. Customers can also leverage application-specific analysis options which allow them to access results and perform customised equipment recommendations directly on their mobiles or tablet devices, saving them from unnecessary downtime that could affect production output and delivery deadlines.

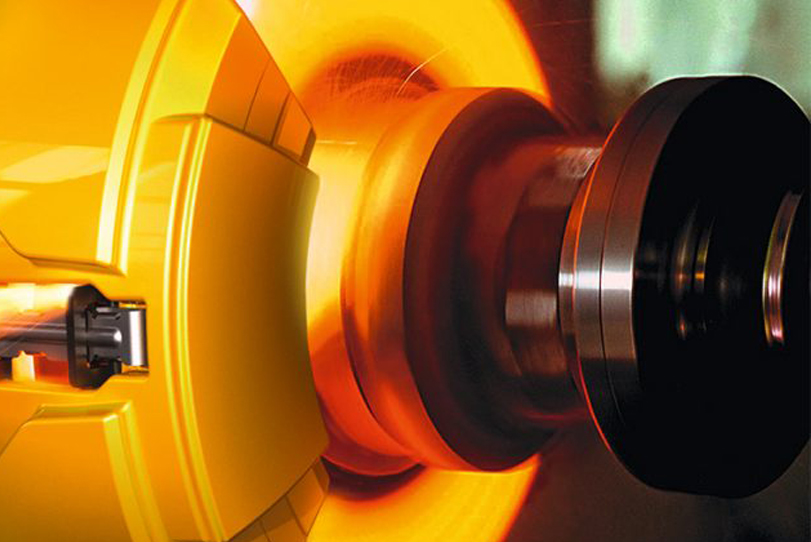

With the MSLA program, operators can look forward to increased productivity and performance from their equipment – the analysis helps identify issues that can be mitigated with minimal downtime, reduce the amount of lubricant needed to operate machinery, and improve and extend overall machine life.

For more than 150 years, ExxonMobil has delivered an extensive range of leading technical services to help customers optimise their maintenance programs, enhance equipment performance and ensure safety, all of which have been brought together under the Mobil Serv brand to help deliver these services to customers more efficiently.

This in line with Industry 4.0, where companies need to understand its technological implications on their businesses and be prepared to adapt and leverage on these technologies to their advantage. The industrial revolution might take a few decades to be fully realised but with key technological advances like MSLA being rolled out and adopted in the next few years, companies can look towards making significant progress toward building and operating smart factories.

With Industry 4.0 being all about a connected world, one cannot rule out the intervention of social media. ExxonMobil continues to strive towards product and service excellence, keeping abreast of the best and the next practices. It leverages LinkedIn to connect with industry and customers at large through digital engagement campaigns to share content relevant to industry, in the form of articles. It is also used for product and service communication and well as content placement via partner messages and other properties to the sector specific customers.

In addition to the MSLA program and LinkedIn, ExxonMobil has created interactive platforms such as the Mobil SHC Club, which is an online community to connect with lubrication experts from around the world. It is an interactive platform where registered users can ask questions on lubrication industry and seek responses from experts, participate in quiz, listen to industry talks and attend webinars. Opinion leaders from the industry share lubrication insights and tips, which are share with registered users on weekly basis. It has a connection to a network of 2,000 industry professionals.

One can ask as well as connect on topics ranging from water contamination to the importance of viscosity in grease selection or even whether synthetic ester-based hydraulic fluids are the best eco-friendly choice. So, if customers want to know how lubricants can enhance safety at an Italian steel mill or why mines should continue to invest in equipment maintenance or even what are the impacts of natural refrigerants on lubricants? All this and more can be availed of through the Mobil SHC Club.

Lastly, with mobile interface as a key interactive platform today, ExxonMobil Fuels & Lubricants has also rolled out the Mobil Performance app, which is an insightful app that has been developed to highlight ExxonMobil’s work from around the world, developing some of the world’s most recognised synthetic oil brands. Invited users can view additional materials based on their preferences.

For more information about Mobil Serv, visit mobilindustrial.com, and for more information about Mobil Serv Lubricant Analysis, visit mobilserv.mobil.com.

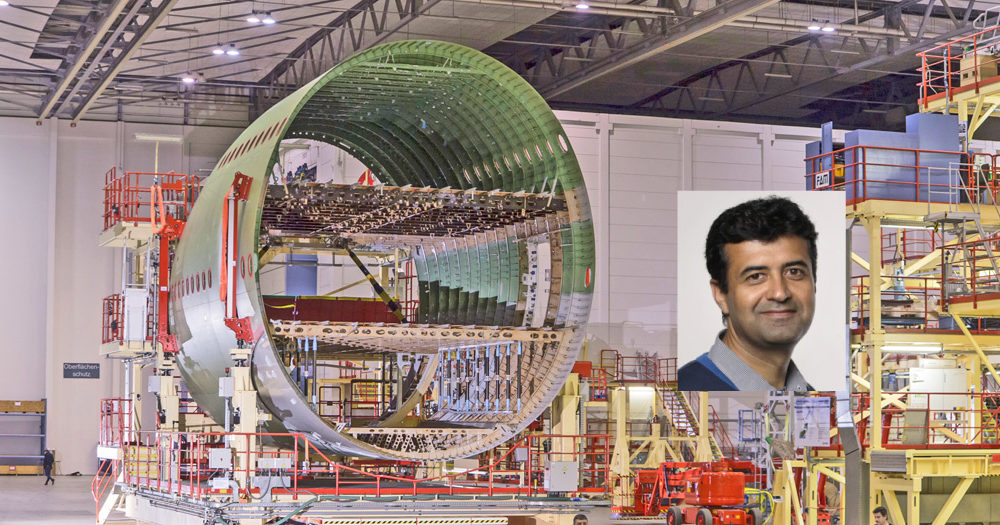

Authored by:

Imtiaz Ahmed,

Asia Pacific Mobil SHC Brand Manager,

ExxonMobil Lubricants Pvt Ltd

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.