Effect of Industry 4.0

By OEM Update Editorial April 12, 2022 2:24 pm IST

Efficiently increase production while improving safety, which has become a more prominent factor when evaluating machine efficiency.

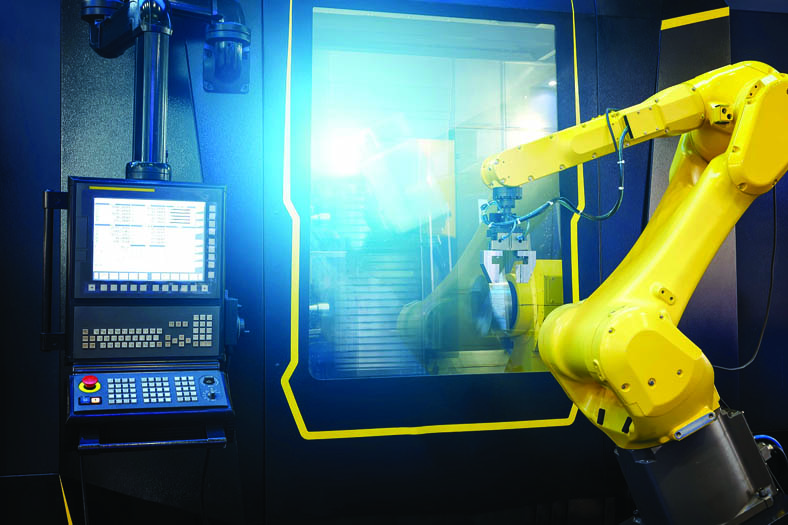

In the past the thought of integrating machine safety was not part of the initial machine design or manufacturing process considerations for many. Until recently, the advancements in automation technology have been centred on producing faster and more efficient equipment that will ultimately provide more output. Today safety has become a more prominent factor when evaluating machine efficiency, in many cases due to operator interaction with the machine. This can be seen with global adaptation of numerous harmonised international safety standards. The current manufacturing goal has shifted to producing a faster and more efficient output while maintaining the safest working environment for both operator and machine. Trying to combine cutting edge technology with rigorous safety requirements is the driving force behind what is known as Industry 4.0, a German concept with a global objective.

Technological advancements within the industrial world have continually changed the automation and safety aspect of the manufacturing process for the better. What a modern manufacturing plant is able to accomplish today is a drastic improvement from the capabilities of what the early production lines were able to achieve in the past. Engineering is constantly evolving and the ability of what can be offered within a manufacturing process today and in the near future is awe-inspiring.

The primary engineering questions to any process are generally (1) how can we make the process easier? and (2) how can we make the process more efficient? These questions are usually addressed by creative inventions and altering current technology to fulfil a new need. Gradually over time the new technology and the methods in which they are used lead to the improvement of a process, as in the case with the steam engine in the early to mid-1700’s. By the early 1780’s this technical marvel transformed into a vital component for the manufacturing plant and a key factor for the Industrial Revolution; what can be considered Industry 1.0. One question that we have yet to explore as it was not a primary focus at this time is how do we make the process safer?

Although the first industrial revolution changed the way production was accomplished it is not the template for what we know today. The second industrial revolution which started in 1870 was marked by the introduction of the electrical plant and machine tools for mass production. This Industry 2.0 format began the frame-work of the common production lines. It also provided early signs of a safer working environment by allowing machines to perform lifting and placement of material rather than manual operation.

Even with the technical achievements within Industry 2.0 the question of a more efficient process still existed and the answer this time led to the birth of the Programmable Logic Controller and Industry 3.0. In the late 1960’s the Programing Logic Controller (PLC) was implemented within the automotive industry to streamline hardwired logic relay systems.

The PLC, as well as the production lines from the second Industrial Revolution, has advanced dramatically along with the requirements for operator safety. A PLC is a staple in any automation process seen today, providing hundreds of inputs and outputs and executing hundreds of thousands of commands. A safety PLC incorporates these functions with redundant monitoring of safety systems. Safety functions and automation processes can coexist within one system communicating with various other systems plant-wide over a given network.

The concept of a smart factory is the framework behind Industry 4.0; a concept defined by a German work-shop revealed during the 2011 Hanover Fair by government officials and industrial leaders. Industry 4.0 is geared towards manufacturing and in essence will utilise parts of a similar concept named the internet of Things (IoT) which focuses on the overall cyber-physical systems (computation, networking, and physical processes).Industry 4.0 goes beyond just two pieces of machines communicating with each other. The overall vision embraces a production plant with limited human interaction. To achieve this, machine data of both automation and safety needs to be collected, stored, shared and manipulated through a centralised cloud point of Human Machine Interface, or HMI, operation. Expanding further on this computing power, the ability to assist the operator in decision making based on real time statistical data. How do we arrive at Industry 4.0 efficiently while complying with the rigorous requirements for operator safety? Today’s major safety component manufacturers offer electronic safety devices which feature many innovative benefits over traditional electromechanical devices such as network communication of its status. This can provide swift diagnoses when trouble-shooting resulting in decreased machine downtime. Most of these devices are designed to meet the highest stringent requirements of current international safety standards such ISO 13849, ISO 14119 and IEC 61508. Following these industrial consensus standards usually leads to fulfilling and even exceeding OSHA regulations. Furthermore, properly selected and installed electronic devices tend to have a higher life cycle due to the reduced wear and tear and typically offer easier wiring for reduced installation times and costs. Combined this with the monitoring and communication of a safety PLC and the safety aspect of Industry 4.0 can turn from a theory into a reality.

Industry 4.0 in its entirety is still taking shape as we are in the presence of this 4th Industrial Revolution. Only time will tell to what extent the smart factory will be realised. Based on previous revolutions and the current state of technology turnover, it is certain that tomorrow’s plant will be a transformation that will forever change the way we produce on a global scale. The main improvement with Industry 4.0 over the previous industries is that worker safety is now at the forefront; which already means we are moving in a better direction.

Contributed by:

Devin Murray

Functional Safety Engineer,

TÜV Rheinland ID-No. 4274/11 Machinery

Schmersal USA.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.