Evolving manufacturing trends: A glimpse into 2024

By OEM Update Editorial April 23, 2024 3:41 pm IST

According to Frans Van Neikerk, Managing Director, Atlas Copco (India), the year 2024 marks a convergence of technological advancements, the need for sustainability, and radical changes in manufacturing methodologies. He explains that this crucial point underscores a transition towards enhanced efficiency, creativity, and environmental consciousness within the industry.

Analysis of the prevailing trends in manufacturing during 2024 reveals that a new approach to production is being indicated during this period.

Rise of smart factories

The emergence of smart factories is reshaping traditional manufacturing practices. By 2024, these facilities will have integrated systems, artificial intelligence (AI), and the Internet of Things (IoT) to ensure smooth and autonomous operations. These factories enhance efficiency and minimise downtime by employing adaptive manufacturing methods, real-time data analysis, and predictive maintenance to optimise production.

Additive manufacturing advancements

In 2024, additive manufacturing—also called 3D printing—undergoes a revolution. The technique advances beyond its earlier constraints, enabling mass production of complex and robust components in addition to prototyping. Improved printing materials and quicker printing rates strengthen its viability across several industries, enabling on-demand, localised production and customisation.

Embrace of sustainable practices

In manufacturing, sustainability becomes a non-negotiable focal point. In 2024, companies will prioritise adopting circular economy models, optimising resource utilisation, integrating renewable energy sources, and adopting eco-friendly practices. Manufacturers respond to the growing demand for environmentally conscious products by aligning their operations with sustainable development goals, which include lowering carbon footprints and adopting recyclable materials.

Reshoring and localised production

Manufacturing strategies are being reevaluated globally, with a growing focus on localised production and reshoring. Companies are reevaluating outsourcing due to factors like supply chain interruptions, geopolitical concerns, and the value placed on agility. By locating their manufacturing facilities closer to consumer markets, manufacturers can reduce costs, shorten lead times, and better respond to shifting consumer demands.

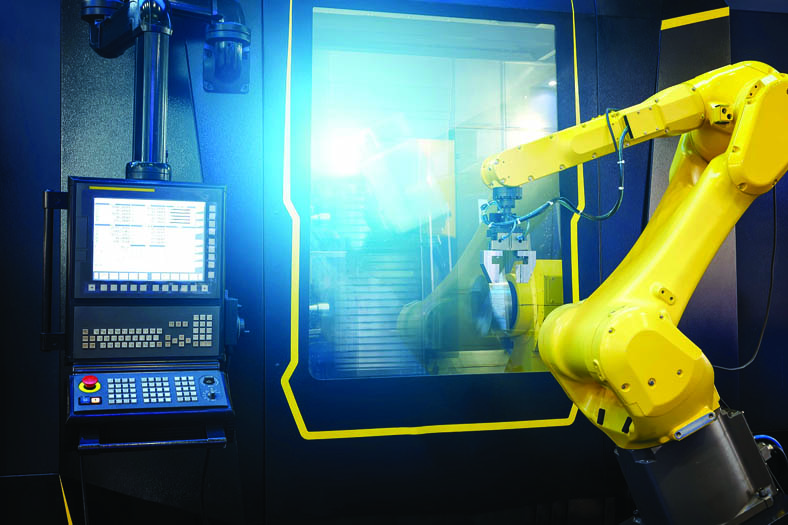

Human-Machine collaborationIn 2024, human-machine cooperation takes on a new significance. As automation becomes more widespread, there is a growing focus on enhancing the collaboration and synergy between humans and machines. Collaborative robotics, virtual reality (VR), and augmented reality (AR) promote safer and more productive work environments. Employees are more proficient in managing, programming, and working with intelligent equipment, which boosts output quality and productivity.

Data security and digital resilience

As digital technology becomes increasingly intertwined with everyday activities, cybersecurity and digital resilience become more important. By 2024, manufacturers will have significantly invested in strong cybersecurity defences to protect intellectual property, production systems, and sensitive data. Utilising AI-powered threat detection and response systems alongside a proactive cybersecurity strategy enhances the industry’s ability to defend against evolving cyber threats.

Personalisation and customer-centric manufacturing

The shift towards customer-centric manufacturing models emphasises the prominence of the era of mass customisation. By utilising advanced analytics and artificial intelligence (AI), businesses are empowered to produce personalised products on a large scale, leveraging a comprehensive comprehension of consumer preferences. Manufacturing practices in 2024 are geared towards catering to specific consumer demands, ranging from personalised clothing to tailored electronics, thereby bolstering brand loyalty and establishing a competitive edge.

Biotechnology integration in manufacturing

In 2024, traditional industrial methods will be disrupted by biotechnology integration. The combination of biotechnology and manufacturing is revolutionising material supply and production processes, from bio-fabrication for textiles to bioengineered materials. Bio-based manufacturing methods and sustainable biomaterials emerge as workable substitutes that minimise environmental impact and depend less on conventional resources.

In 2024, manufacturing will be shaped by technological advancement, sustainability requirements, and adaptable strategies. This transformative phase is defined by smart factories’ emergence, additive manufacturing advancements, sustainability initiatives, reshoring efforts, and the harmonious integration of humans and robots. Adopting these trends propels the industry towards a more sustainable and consumer-centric trajectory, enhancing operational efficiency and productivity. These developments pave the way for a future reimagined and vibrant industrial environment as manufacturing continues to evolve.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.